Why Your Business Needs a 3D Printer: Unlock New Possibilities Today

In today's fast-paced business environment, innovation is key to staying competitive, and one of the most transformative technologies driving this innovation is the 3D printer for business applications. Industry expert Dr. Alan Smith, a recognized leader in additive manufacturing technologies, emphasizes the potential of this tool by stating, "3D printing allows businesses to prototype and produce products faster and more economically than traditional methods, unlocking new realms of creativity and efficiency."

By integrating a 3D printer into their operations, companies can streamline their design processes, reduce production costs, and ultimately create customized solutions that meet the specific needs of their customers. This technology enables businesses not only to enhance their product offerings but also to respond swiftly to market demands and shifts. As such, investing in a 3D printer for business becomes not just a choice, but a strategic move to foster innovation, enhance productivity, and stay ahead of the competition in a rapidly evolving market landscape.

With the ability to print complex geometries and reduce lead times, the 3D printer for business is revolutionizing industries from manufacturing to healthcare, making it an essential tool for modern enterprises looking to thrive in the 21st century.

The Rise of 3D Printing in Modern Business: A Statistical Overview

The rise of 3D printing technology in modern business has transformed various industries by enabling unprecedented levels of innovation and efficiency. Statistics reveal a significant surge in the adoption of 3D printing, with more than 75% of manufacturers reporting that they have implemented this technology into their operations. This surge is driven by factors such as reduced lead times, lower costs for prototype development, and the ability to create highly customized products that meet specific consumer demands.

Moreover, the economic impact of 3D printing is hard to overlook. A recent report indicated that the global 3D printing market is expected to grow to over $34 billion by 2024, marking a compound annual growth rate of over 25%. This growth underscores the potential for businesses to leverage 3D printing to streamline production processes, enhance product offerings, and gain a competitive edge. Industries ranging from automotive to healthcare are increasingly capitalizing on these capabilities to improve supply chain efficiency and deliver high-quality products at a lower cost, making 3D printing an essential component of contemporary business strategy.

Understanding the Cost-Effectiveness of 3D Printing for Small Enterprises

The cost-effectiveness of 3D printing is increasingly making it an attractive option for small enterprises looking to innovate and streamline their operations. One of the primary benefits is the reduction of production costs associated with traditional manufacturing methods. With 3D printing, businesses can create prototypes and final products on demand, minimizing the need for large inventory investments and reducing waste. This approach not only saves money but also allows for quicker iterations, enabling small businesses to respond rapidly to market needs.

Tips for small enterprises considering 3D printing include starting with a clear project goal to identify how 3D printing can best serve your needs. This might involve mapping out the design process and understanding the specific requirements of the printed object. It’s also important to evaluate materials and technologies available within the realm of 3D printing to ensure that your chosen method aligns with your business model and budget.

Moreover, investing in 3D printing not only streamlines production but can also open the door to unique customization opportunities. Enterprises can leverage this technology to offer personalized products that stand out in a crowded marketplace. By thinking creatively about how to incorporate 3D printing into your business strategy, you can enhance your product offerings while controlling costs effectively.

Exploring Industry Applications: From Prototyping to Production

3D printing technology is revolutionizing various industries, paving the way for enhanced creativity and efficiency in product development. One of the most significant applications is prototyping, where businesses can rapidly produce physical models of their designs. This ability to create tangible prototypes allows companies to test form, fit, and function at an early stage, reducing the risk of costly errors in later production phases. Designers and engineers benefit from the iterative nature of 3D printing, making adjustments and improvements in real-time based on feedback and testing results.

Beyond prototyping, 3D printing extends its capabilities into full-scale production, enabling businesses to manufacture customized products on demand. This adaptability helps companies meet specific customer needs without the constraints of traditional manufacturing methods, which often involve long lead times and large minimum order quantities. Industries such as healthcare, automotive, and aerospace utilize 3D printing to create complex parts, improve designs, and even produce end-use products. By embracing 3D printing, businesses can not only streamline their production processes but also explore innovative designs that were previously impossible, unlocking new possibilities in their sectors.

Why Your Business Needs a 3D Printer: Unlock New Possibilities Today - Exploring Industry Applications: From Prototyping to Production

| Application | Description | Benefits | Industry |

|---|---|---|---|

| Prototyping | Rapid development of prototypes to test ideas. | Faster feedback, reduced costs, and improved designs. | All Industries |

| Manufacturing | Production of complex parts with minimal waste. | Cost savings, flexibility in design, and less material waste. | Aerospace, Automotive, Healthcare |

| Custom Products | Personalized items tailored to customer specifications. | Enhanced customer satisfaction and unique offerings. | Fashion, Gadgets, Home Decor |

| Medical Devices | Creation of bespoke implants and prosthetics. | Improved fit and function for patients, faster production. | Healthcare |

| Architecture | Building physical models from digital designs. | Enhanced presentations and client engagement. | Construction, Real Estate |

Enhancing Customization Capabilities with 3D Printing Technology

Customization has become a cornerstone for businesses aiming to stand out in today's competitive market, and 3D printing technology has revolutionized this capability. With the ability to produce unique designs on demand, companies can tailor their offerings to meet the specific needs and preferences of their customers. This not only enhances customer satisfaction but also fosters a deeper emotional connection with the brand, as consumers feel that their individual needs are being addressed.

One of the key advantages of integrating 3D printing into your business is the reduction of lead times for custom products. Traditional manufacturing methods often require extensive tooling and setup, leading to delays. In contrast, 3D printing allows rapid prototyping, enabling businesses to iterate designs quickly and deliver customized products faster. This agility can give companies a significant edge, allowing them to respond to market trends and customer requests with unprecedented speed.

Tips for implementing 3D printing in your business include starting small with prototypes to test design ideas before full-scale production. This minimizes risk and investment. Additionally, consider utilizing design software that eases the transition into 3D modeling, making it accessible even to those without extensive engineering backgrounds. Embrace feedback from your customers on designs created, as this input can inform future iterations and further enhance the customization capabilities of your offerings.

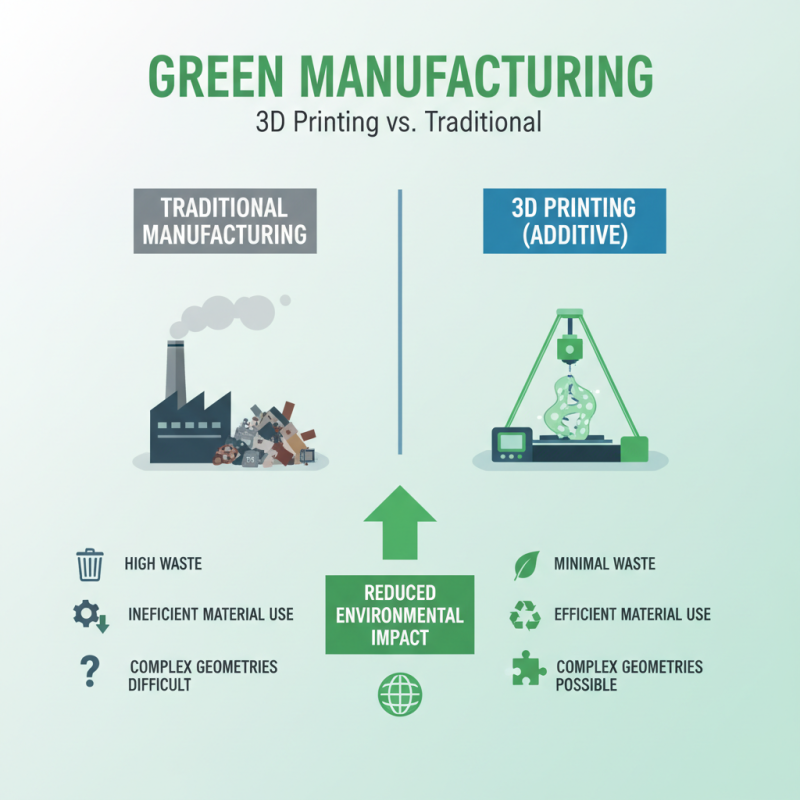

Evaluating the Environmental Impact of 3D Printing in Manufacturing

As businesses look for innovative solutions to streamline production and reduce costs, the environmental impact of manufacturing processes becomes increasingly critical. 3D printing, or additive manufacturing, offers a compelling alternative by minimizing waste and utilizing materials more efficiently. Traditional manufacturing often results in substantial scrap material, while 3D printing typically uses only the materials necessary to create a part, significantly reducing the volume of waste generated. This shift not only lessens the environmental footprint but also allows for the production of complex geometries that are often impossible with conventional methods.

Moreover, 3D printing promotes sustainability through the potential use of recycled materials and bio-based filaments. Companies can develop products that leverage these eco-friendly materials, thus further contributing to a circular economy. Additionally, localized production enabled by 3D printing can diminish the need for extensive shipping and transportation, effectively cutting down carbon emissions associated with logistics. By investing in 3D printing technology, businesses can not only innovate their product lines but also align themselves with environmentally responsible practices that resonate with today’s conscientious consumers.

Related Posts

-

Ultimate Guide to the Most Efficient High Volume 3D Printers in 2023

-

Unlocking Industry Standards for 3D Printers How to Choose the Best Fit for Your Business Needs

-

Digital Insights and Tips for Choosing the Best Industrial 3D Printer

-

Unlocking the Competitive Edge in Manufacturing with the Best High End 3D Printer Benefits for Global Buyers

-

How to Choose the Right 3D Printer for Your Business Needs Based on Industry Trends

-

Unlocking the Future of Manufacturing Through 3D Machine Printing Innovations and Industry Transformations