Ultimate Guide to Top 3D Machine Printers: A Comprehensive Comparison for Global Buyers

As the demand for additive manufacturing continues to surge, the global market for 3D machine printers has seen exponential growth, projected to reach $35.4 billion by 2025 according to a recent market research report. With advancements in technology and materials, businesses across various industries are increasingly relying on 3D machine printers for rapid prototyping, production, and even custom manufacturing. However, purchasing a 3D machine printer involves more than just the initial investment; the importance of post-sale service advantages and maintenance costs cannot be understated. This comprehensive guide will delve into the top 3D machine printers available today, providing buyers with a critical comparison that highlights not only performance metrics but also the long-term operational costs associated with each model. Whether you're a seasoned professional or a newcomer to the world of 3D printing, understanding these factors can empower you to make an informed decision that aligns with your specific needs.

Understanding Industry Standards for 3D Printing Machines: What Buyers Need to Know

When navigating the world of 3D printing, understanding industry standards is crucial for buyers looking to invest in reliable machines. These standards encompass various factors such as print quality, speed, material compatibility, and safety regulations. By familiarizing themselves with these benchmarks, buyers can make informed decisions that align with their specific needs and applications. For example, the resolution of print layers is a significant metric; higher resolutions deliver finer details but may also increase print time and material usage.

Moreover, different industries have distinct requirements which influence the choice of a 3D printer. For instance, the aerospace and medical sectors typically demand machines that can work with high-performance materials and maintain stringent compliance with safety and quality standards. Conversely, hobbyists may prioritize affordability and ease of use.

Understanding these industry-specific standards not only enhances a buyer's ability to select a suitable 3D printer but also ensures that it adheres to safety and performance guidelines, ultimately leading to more successful and efficient production processes.

Key Features to Consider When Choosing the Right 3D Printer for Your Needs

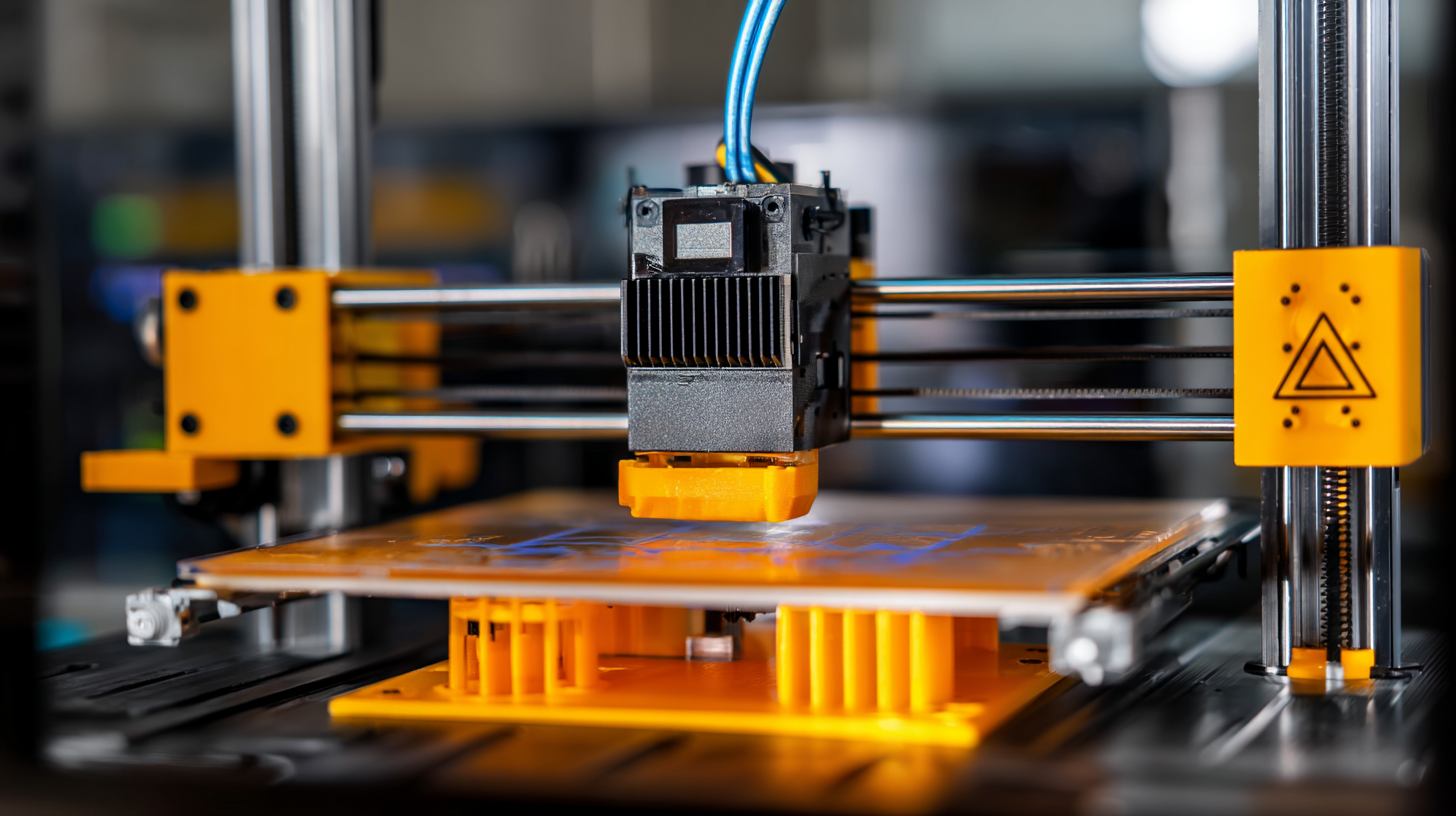

When exploring the world of 3D printing, selecting the right printer to suit your unique needs can be a daunting task. To make an informed choice, consider key features such as build volume, print quality, and material compatibility. The build volume determines the maximum size of your creations; larger volumes are essential for ambitious projects, while smaller ones may suffice for detailed miniatures. Moreover, a printer’s resolution plays a crucial role in the quality of the final prints. A higher resolution often translates to finer details and smoother finishes, making it a vital specification to compare during your selection process.

Another important factor to consider is material compatibility, as different printers support various filaments and resins. If you plan to work with specific materials, such as PLA, ABS, or flexible filaments, ensure the printer you choose can accommodate them. Additionally, user-friendly features such as touchscreen interfaces, connectivity options, and reliable customer support can enhance your 3D printing experience. As technology evolves, staying updated with the latest advancements and user reviews can also aid in making the best decision for your 3D printing endeavors.

Ultimate Guide to Top 3D Machine Printers: A Comprehensive Comparison for Global Buyers

| Feature | Printer A | Printer B | Printer C |

|---|---|---|---|

| Build Volume | 230 x 230 x 250 mm | 300 x 300 x 400 mm | 250 x 250 x 200 mm |

| Layer Resolution | 0.1 mm - 0.3 mm | 0.05 mm - 0.4 mm | 0.1 mm - 0.2 mm |

| Printing Speed | 60 mm/s | 80 mm/s | 50 mm/s |

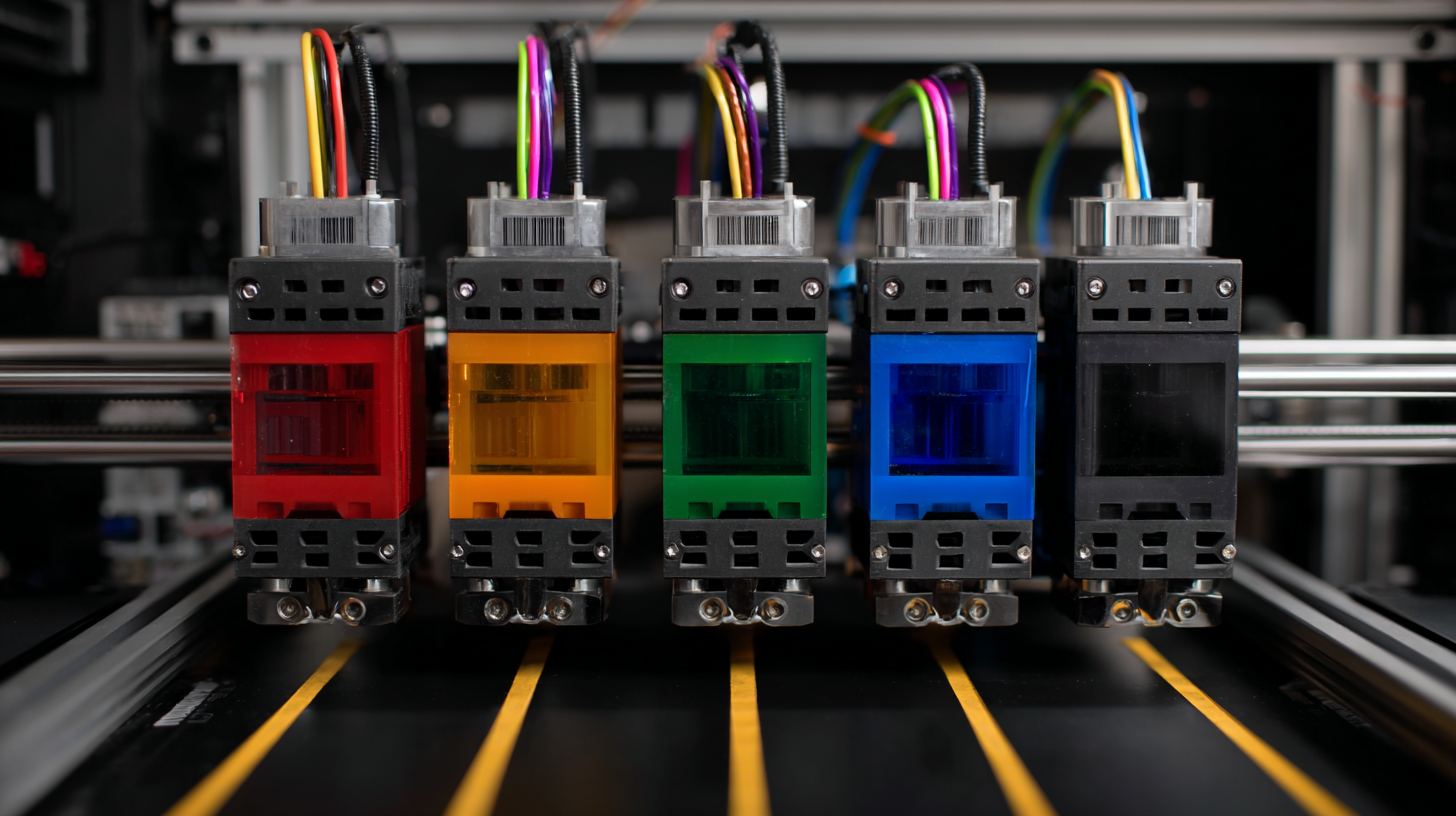

| Extruder Type | Single | Dual | Single |

| Filament Compatibility | PLA, ABS, PETG | PLA, ABS, TPU, PETG | PLA, ABS |

| Connectivity Options | USB, SD Card, Wi-Fi | USB, SD Card, Ethernet | USB, SD Card |

| Price Range | $300 - $400 | $500 - $700 | $250 - $350 |

Comparative Analysis of the Top 3D Printers: Performance, Cost, and Reliability

The 3D printer market is rapidly evolving, driven by a growing demand for efficient, flexible, and high-quality production solutions. As enterprises embrace Industry 4.0, comparative analyses of top 3D printers become crucial for buyers globally. A focus on performance, cost, and reliability helps potential customers make informed decisions in a competitive landscape.

When considering a 3D printer, it is essential to assess the specific application needs. For instance, in the dental sector, printers designed for in-office use or lab environments cater to distinct requirements. Additionally, different technologies like Stereolithography (SLA) and Fused Deposition Modeling (FDM) offer varying levels of precision and material compatibility.

Tips: First, identify the materials you'll be using and ensure the printer supports them. Second, evaluate the total cost of ownership, including maintenance and material costs, in addition to the initial purchase price. Lastly, check for customer support options and warranty services, as reliable assistance can significantly impact your long-term satisfaction with your investment.

Insights into 3D Printing Technologies: FDM, SLA, and SLS Explained

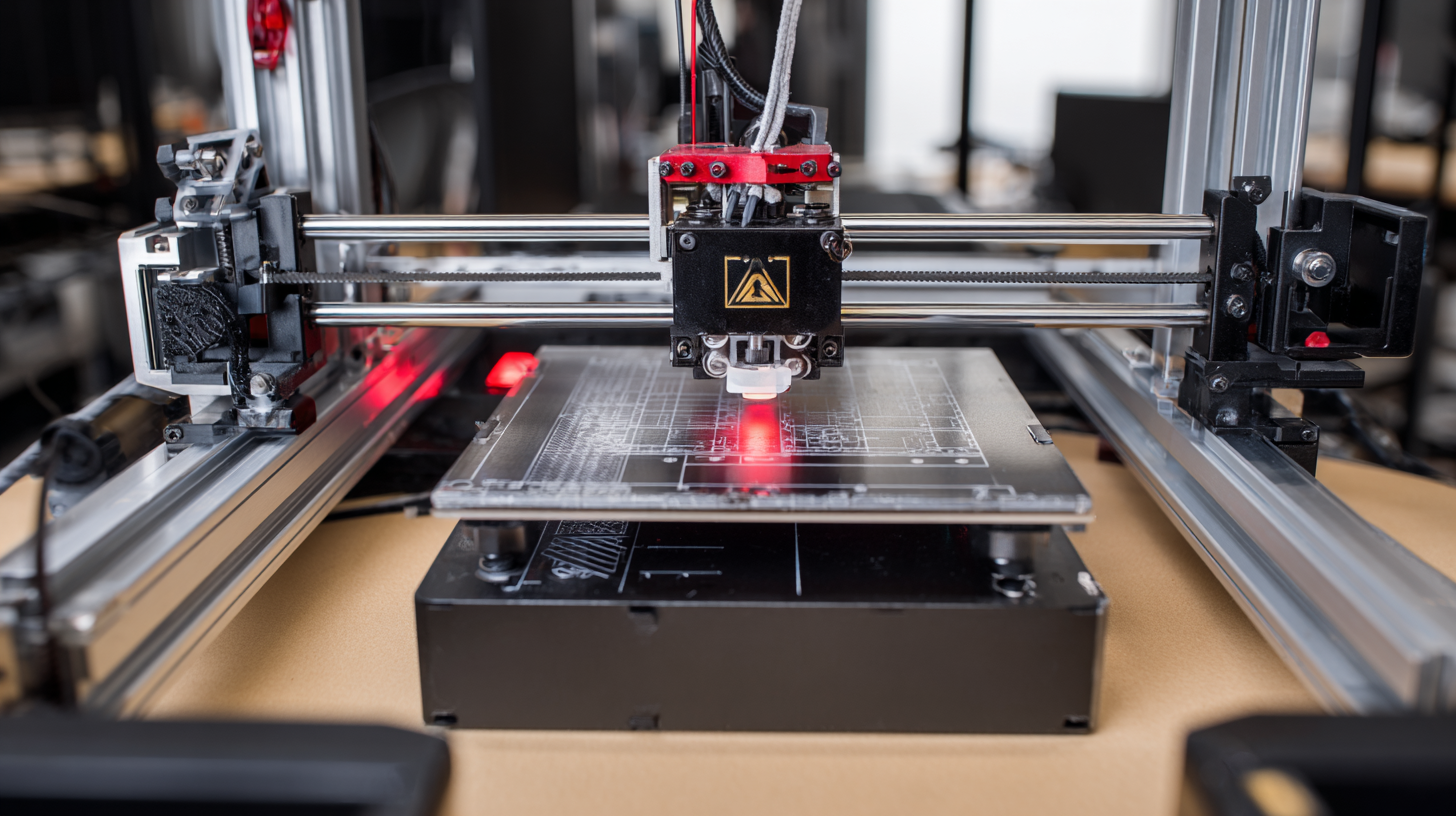

3D printing technology has evolved significantly, with three primary methods dominating the landscape: Fused Deposition Modeling (FDM), Stereolithography (SLA), and Selective Laser Sintering (SLS). FDM is well-known for its accessibility and cost-effectiveness, making it an ideal choice for hobbyists and small businesses. This technology uses thermoplastic filaments, enabling a vast range of materials to be utilized, though it may sacrifice some mechanical properties.

SLA, on the other hand, excels in producing high-resolution prints with intricate details, owing to its layer-by-layer curing of liquid resin using a laser. This method is particularly favored in industries like dental and jewelry, where precision is paramount. Recent studies, including a systematic review, illustrate how SLA and SLS provide superior flexural strength in applications such as dental prostheses, enhancing durability and fracture resistance.

SLS operates differently by using a laser to fuse powdered materials, resulting in robust, fully functional parts ideal for industrial applications. The growth of the industrial 3D printing market, projected to reach significant valuations by 2031, underscores the importance of these technologies in modern manufacturing. As advancements continue to optimize the performance of 3D-printed materials, the future of additive manufacturing looks promising, presenting new opportunities across various sectors.

How to Maintain Your 3D Printer: Tips for Longevity and Optimal Performance

Maintaining your 3D printer is crucial to ensuring its longevity and optimal performance. Regular maintenance involves a few key practices that every printer owner should adopt. Start by keeping the printer clean; dust and debris can affect the quality of your prints and the printer's inner workings. Use a soft brush or a can of compressed air to keep the nozzle and build plate free from particles. Additionally, lubricate moving parts such as rods and rails periodically to prevent wear and tear, ensuring smoother operation.

Another important aspect of maintenance is monitoring the software and firmware of your 3D printer. Regular updates can fix bugs and improve functionality, which ultimately enhances print quality. It's also wise to keep an eye on the condition of your print bed and nozzle; replacing worn-out components can make a significant difference in print accuracy and surface finish. By incorporating these maintenance tips into your routine, you can prolong the life of your 3D printer and enjoy consistently high-quality prints.