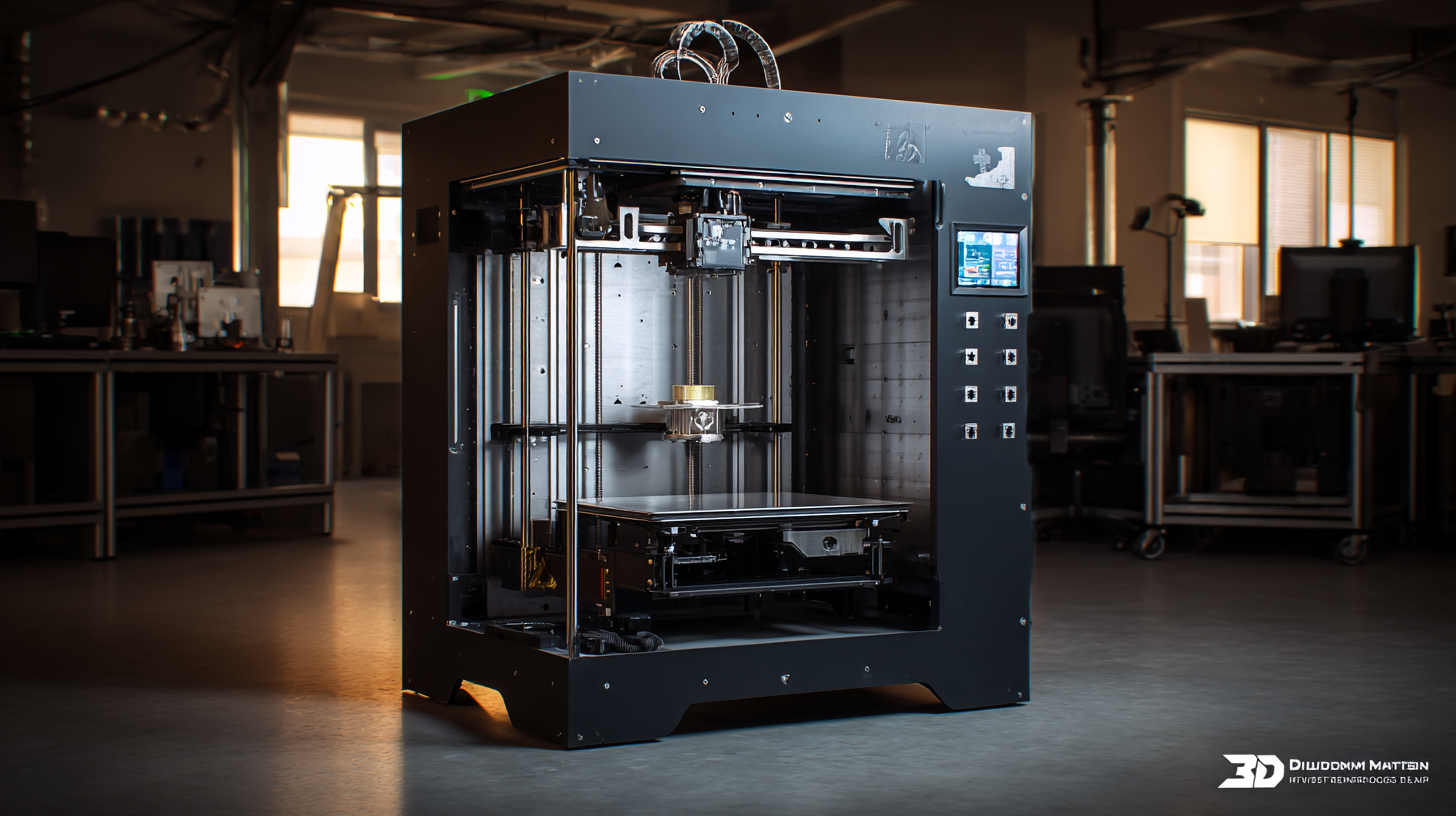

What is the Ultimate 3D Printing Solution for Metal Manufacturing

In recent years, the aerospace, automotive, and medical industries have increasingly turned to additive manufacturing as a revolutionary approach to metal production. According to a report by Wohlers Associates, the global metal 3D printing market is projected to grow from $1.6 billion in 2021 to over $4 billion by 2026, demonstrating strong demand for advanced technologies like the 3D printer for metal. This growth is fueled by the ability of metal 3D printing to create complex geometries that are often impossible with traditional manufacturing methods. As industries seek more efficient and cost-effective solutions, the ultimate 3D printing technologies are pivotal in simplifying the production process, enhancing material utilization, and reducing lead times, signifying a transformative shift in the way we manufacture metal components.

Introduction to 3D Printing Technologies for Metal Manufacturing

The advancement of 3D printing technologies for metal manufacturing has gained significant momentum, driven by innovations in techniques and materials. Recent developments highlight the large-scale potential for this sector, with projections estimating the global metal 3D printing market will grow from USD 12.04 billion in 2025 to a staggering USD 87.33 billion by 2034. This remarkable growth reflects the industry's accelerating demand for metal printing hardware and advanced materials, opening new avenues for production efficiency and material utilization.

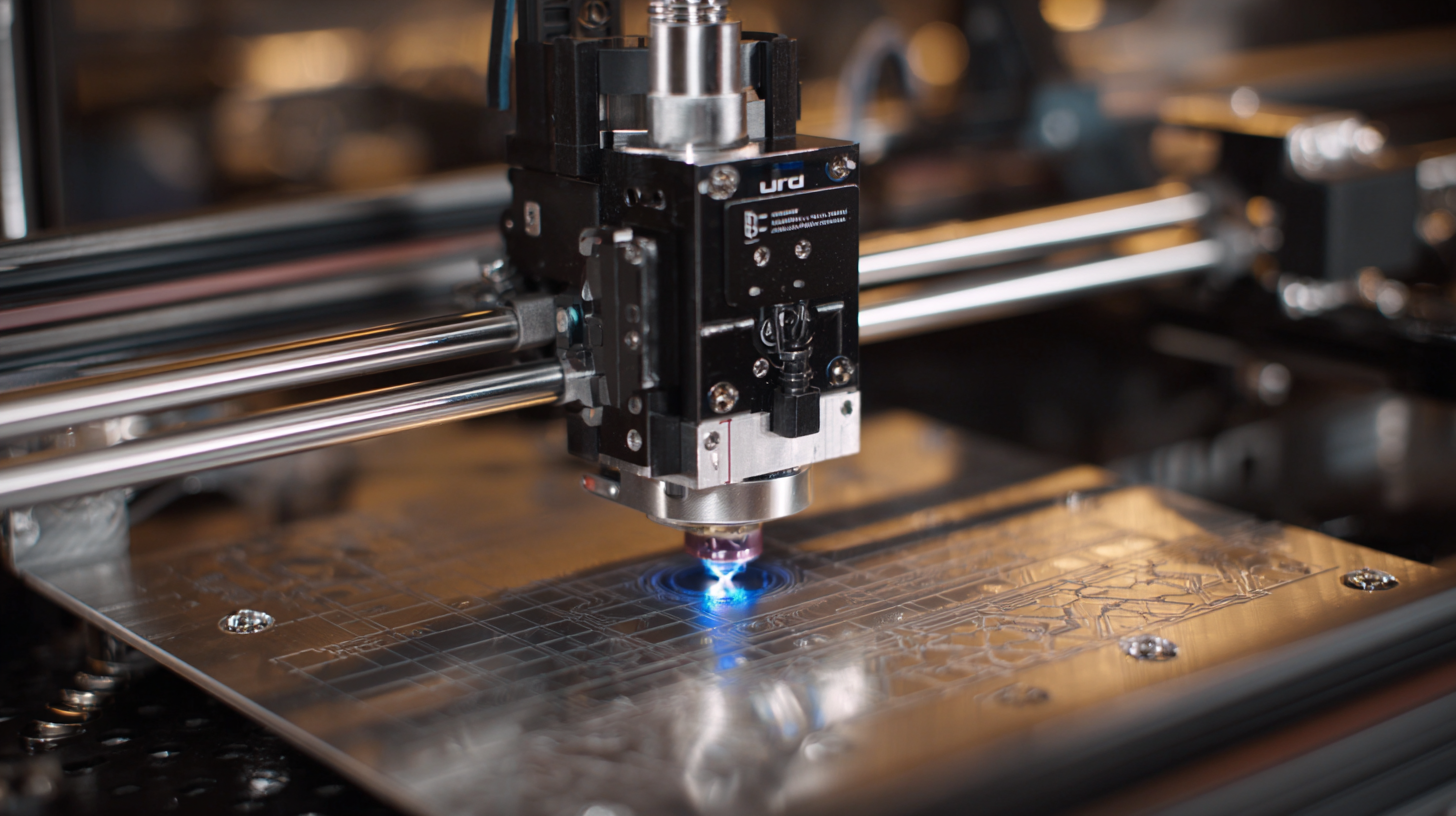

Innovative companies are at the forefront of this transformation. For instance, the introduction of lithography-based metal manufacturing technology has enabled the rapid production of small, high-resolution parts, with lead times reduced to just 5 to 7 days. This not only enhances manufacturing capabilities but also positions companies to meet the increasing needs of various industries, including aerospace and healthcare. Moreover, the strategic expansion efforts by leading firms signal a concerted push towards establishing global dominance in the metal 3D printing space, facilitating the integration of additive manufacturing in mission-critical applications.

What is the Ultimate 3D Printing Solution for Metal Manufacturing

| Technology | Material Compatibility | Build Volume (mm) | Layer Thickness (μm) | Applications |

|---|---|---|---|---|

| Selective Laser Melting (SLM) | Stainless Steel, Aluminum, Titanium | 250 x 250 x 300 | 20 - 100 | Aerospace, Medical, Automotive |

| Direct Metal Laser Sintering (DMLS) | Titanium, Inconel, Stainless Steel | 300 x 300 x 400 | 20 - 100 | Tooling, Prototyping, Aerospace |

| Binder Jetting | Aluminum, Stainless Steel, Bronze | 500 x 250 x 200 | 50 - 200 | High volume production, Art, Jewelry |

| Electron Beam Melting (EBM) | Titanium, Cobalt Chrome | 250 x 250 x 300 | 50 - 100 | Medical implants, Aerospace parts |

Overview of Key Benefits of Metal 3D Printing Solutions

Metal 3D printing has transformed the manufacturing landscape, offering unparalleled benefits that make it an ultimate solution for various industries. One of the primary advantages of this technology is its ability to produce complex geometries that are often impossible to achieve with traditional methods. This flexibility allows engineers and designers to innovate without the constraints of conventional machining, leading to lighter, stronger parts optimized for performance.

Additionally, the cost-effectiveness of metal 3D printing has improved significantly with recent advancements. Companies are now able to access more affordable metal printers that integrate seamlessly into existing workflows. For instance, new collaborations in the industry have focused on developing comprehensive solutions that streamline the metal printing process, making it accessible to small and medium-sized manufacturers. This democratization of technology not only reduces production costs but also shortens lead times, enabling quicker iterations and faster time to market for new products.

Step-by-Step Guide to Choosing the Right Metal 3D Printer

When considering a metal 3D printer, one must begin by evaluating key factors that align with your manufacturing goals. Consider the materials you intend to use. Different printers support various metal filaments and powder types, so it's essential to select a printer that accommodates your specific needs. Additionally, think about the scale of your production; a larger build volume could be beneficial for creating bigger parts but may require additional investment.

Tip: Research the compatibility of various metal materials with potential printers. Understanding their properties will help you choose a machine that can produce durable, high-quality parts tailored to your industry.

Next, evaluate the technologies available in the market. Common methods include Direct Metal Laser Sintering (DMLS) and Electron Beam Melting (EBM). Each has its own advantages concerning precision, speed, and cost efficiency. Selecting the right technology is crucial as it directly impacts the overall success of your metal manufacturing process.

Tip: Review several printer models and their specifications to find the optimal balance between speed and quality—sometimes investing in a slightly more advanced machine can save costs in the long run due to fewer post-processing requirements.

Common Materials Used in Metal 3D Printing and Their Applications

In the realm of metal 3D printing, selecting the appropriate materials is crucial for achieving optimal performance and application suitability. Commonly used materials include stainless steel, titanium, aluminum, and cobalt-chrome. Stainless steel is favored for its excellent strength and corrosion resistance, making it ideal for industrial applications where durability is paramount. On the other hand, titanium is renowned for its lightweight and high strength-to-weight ratio, which is why it is extensively used in aerospace and medical implants.

Aluminum, with its outstanding thermal conductivity and low density, is increasingly popular in automotive and aerospace sectors, wherein weight reduction is critical without compromising structural integrity. Additionally, cobalt-chrome alloys are used in precision applications, especially in medical implants, due to their biocompatibility and exceptional wear resistance. Each of these materials brings unique properties that, when paired with advanced 3D printing techniques, can lead to unprecedented design freedom and performance enhancements in metal manufacturing.

Best Practices for Post-Processing Metal 3D Printed Parts

Post-processing is a critical step in the metal 3D printing workflow, significantly influencing the final properties and appearance of printed parts. Techniques such as machining, heat treatment, and surface finishing are essential to enhance strength, reduce residual stresses, and improve surface quality. Each method has unique advantages, and selecting the best practice depends on the specific requirements of the application.

One effective post-processing tip is to utilize heat treatments tailored to the material being printed. For instance, aging treatments can optimize the mechanical properties of aluminum alloys, while stress relief treatments are crucial for stainless steel parts to minimize warping. Additionally, ensure that the parameters are fine-tuned for each batch of prints to achieve consistent results.

Another valuable practice involves surface finishing techniques, which can significantly enhance the aesthetic and functional qualities of the part. Techniques such as bead blasting or chemical polishing can remove unwanted layers or imperfections, leading to smoother surfaces. Always consider the intended use of the part when deciding on the level of finishing required, as it directly impacts performance and durability in practical applications.