Revolutionizing Prototyping: How 3D Systems Printers Are Transforming Manufacturing Efficiency

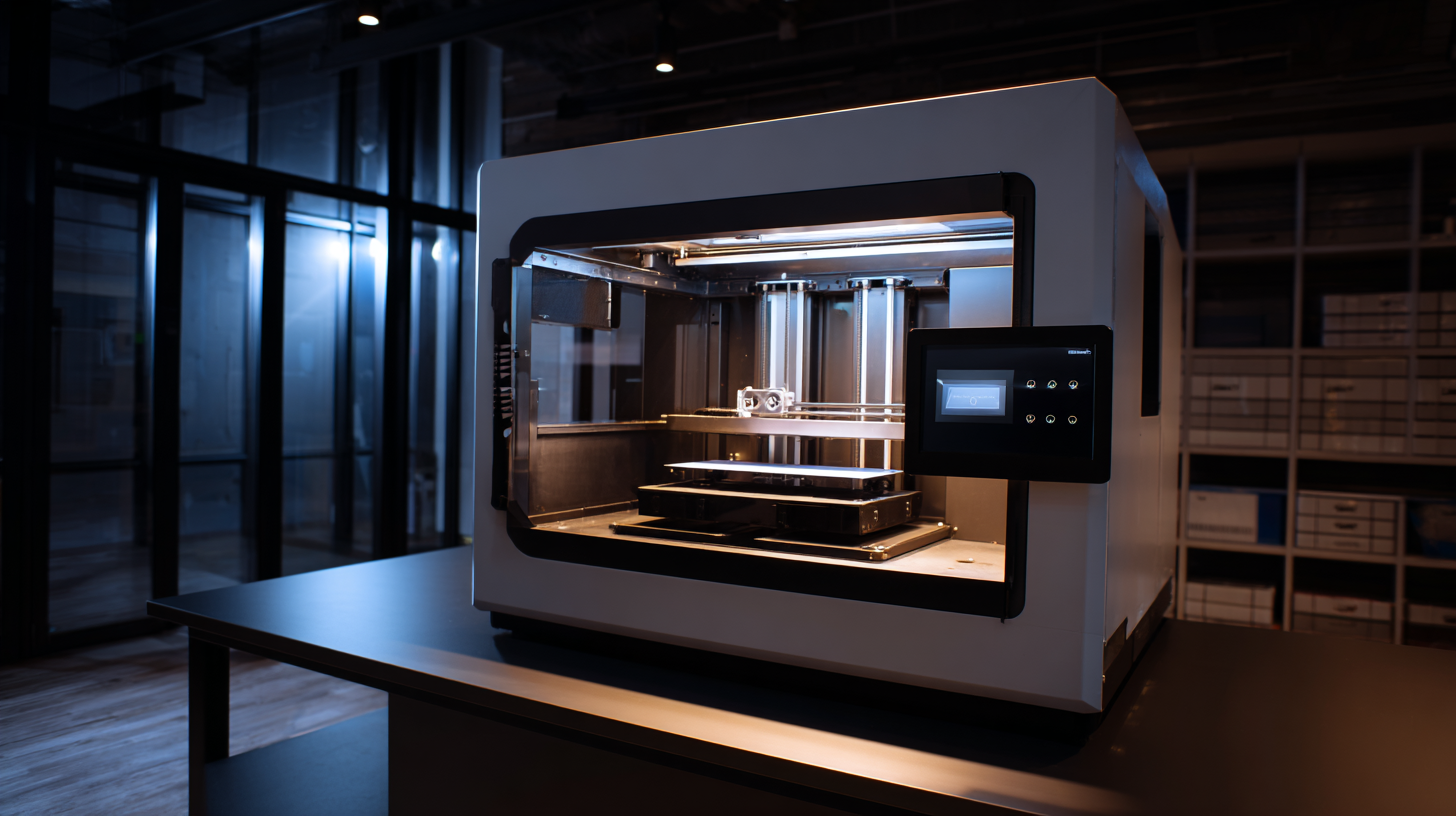

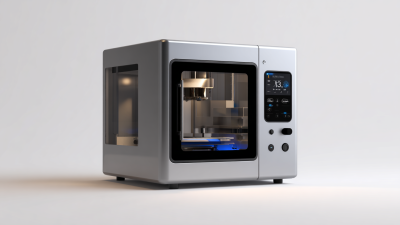

As industries increasingly seek to improve manufacturing efficiency and reduce time-to-market, 3D Systems printers have emerged as pivotal tools in this transformative journey. According to a recent report by Wohlers Associates, the additive manufacturing market is projected to grow to $35.6 billion by 2024, underscoring the rising adoption of advanced 3D printing technologies across various sectors. 3D Systems printers, known for their precision and versatility, enable rapid prototyping and iteration of designs, significantly streamlining the production process. Moreover, these printers facilitate the creation of complex geometries that traditional manufacturing methods struggle to achieve, offering manufacturers a competitive edge. As companies increasingly recognize the cost-saving and efficiency-enhancing benefits of 3D Systems printers, their integration into manufacturing workflows is not just advantageous but essential for staying ahead in a fast-evolving marketplace.

The Role of 3D Printing in Streamlining Manufacturing Processes

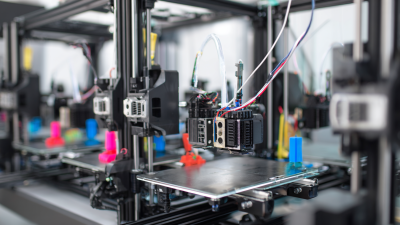

The integration of 3D printing technology into manufacturing processes is revolutionizing efficiency across various industries. By leveraging advancements in artificial intelligence, manufacturers can streamline production workflows, reduce waste, and enhance customization capabilities. AI-driven 3D printing solutions are particularly transformative in sectors like automotive manufacturing, where precision and speed are crucial. Predictive maintenance and autonomous robotic systems are paving the way for more adaptable manufacturing environments, ensuring that processes are not only faster but also smarter.

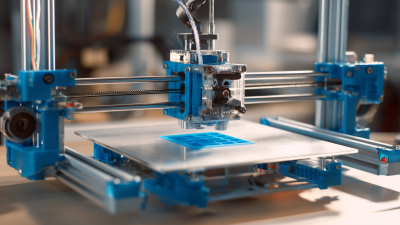

Moreover, the potential of additive manufacturing extends beyond traditional industries. The clothing industry, for instance, is witnessing a fundamental shift as 3D printing allows for innovative designs while addressing sustainability concerns. By utilizing 3D printing, manufacturers can significantly cut down on material usage and energy consumption, aligning with global sustainability goals. Automation solutions, such as those enabling fully integrated production lines, further emphasize the role of technology in optimizing the manufacturing landscape. This synergy between 3D printing and advanced technologies is not just a trend, but a pivotal movement towards the future of efficient and sustainable manufacturing practices.

Revolutionizing Prototyping: How 3D Systems Printers Are Transforming Manufacturing Efficiency

| Dimension | Description | Impact on Manufacturing |

|---|---|---|

| Speed | Rapid prototyping allows for quicker production cycles. | Decreases time-to-market for new products. |

| Cost Efficiency | Reduces material waste through precise additive manufacturing. | Lowers overall production costs. |

| Customization | Allows for personalized designs tailored to specific customer needs. | Increases customer satisfaction and market competitiveness. |

| Material Variety | Utilizes a wide range of materials suitable for various applications. | Enhances product performance and durability. |

| Complexity | Enables the creation of intricate designs that are difficult to achieve with traditional methods. | Fosters innovation in product design and functionality. |

Key Advantages of 3D Systems Printers for Rapid Prototyping

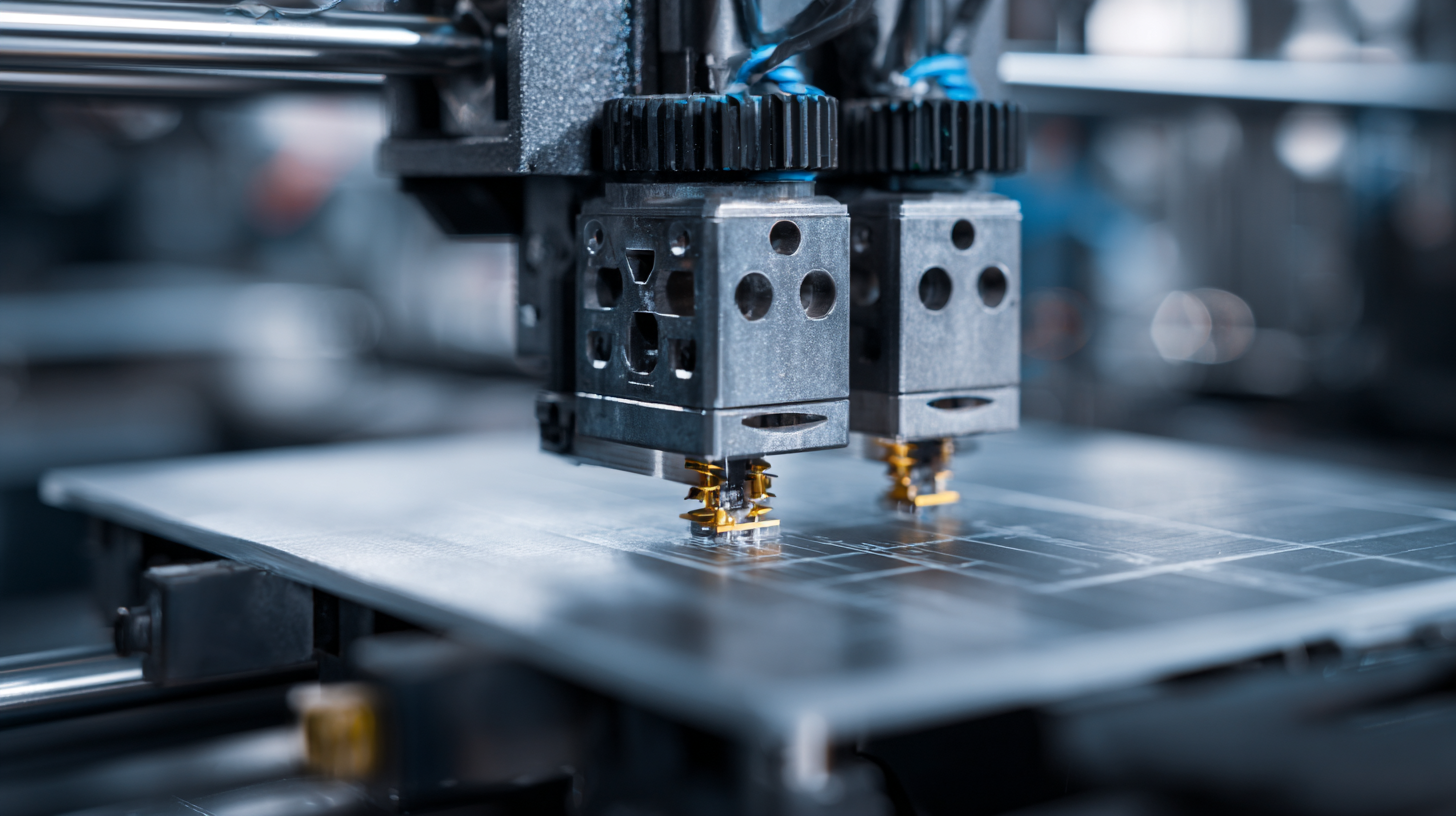

3D printing technology is rapidly revolutionizing the prototyping landscape, offering significant advantages that are reshaping manufacturing efficiency. With an industry projected to reach a market value of **$35.79 billion by 2030**, up from **$16.16 billion in 2025**, the adoption of 3D Systems printers is becoming increasingly vital for industries looking to enhance their production capabilities. Key advantages of these printers include the ability to create complex geometries that traditional manufacturing methods cannot achieve, thereby reducing material waste and increasing design flexibility.

Moreover, advancements in 3D printing processes like Fused Deposition Modeling (FDM), Stereolithography (SLA), and Selective Laser Sintering (SLS) allow manufacturers to utilize a variety of materials, from metals to polymers, tailored to specific applications. For instance, **volumetric 3D printing** has emerged as a groundbreaking approach that produces objects significantly faster than conventional techniques, further driving down lead times. As industries continue to recognize these benefits, the integration of 3D printing technology in sectors such as healthcare, automotive, and mining is expected to flourish, making rapid prototyping a cornerstone of modern manufacturing strategies.

Impact of 3D Printing on Manufacturing Efficiency

Innovative Applications of 3D Printing Across Various Industries

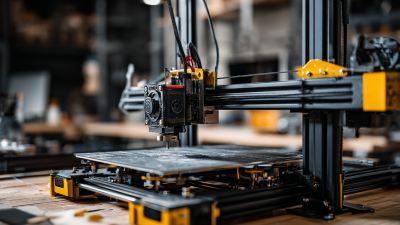

The innovative applications of 3D printing are making significant waves across multiple industries, driving efficiency and creativity in manufacturing processes. In the automotive sector, for instance, 3D printing is being utilized to produce complex components that were previously cumbersome to create. Technologies such as additive manufacturing are enabling manufacturers to reduce material waste and speed up production times. This transformation is reflected in the growing market for 3D printed plastics, which is projected to expand significantly over the next decade, particularly in applications involving aerospace and defense, where precision and performance are crucial.

Additionally, the healthcare industry is witnessing a remarkable shift due to 3D printing, with tailored medical devices and prosthetics becoming a reality. The desktop 3D printing market alone is anticipated to grow from $3.0 billion in 2023 to an impressive $9.5 billion by 2032, showcasing the increasing accessibility of this technology for small-scale production and prototyping. As 3D printing continues to evolve, its role in revolutionizing traditional manufacturing methods becomes more pronounced, indicating a future where innovation is not just a possibility but a standard.

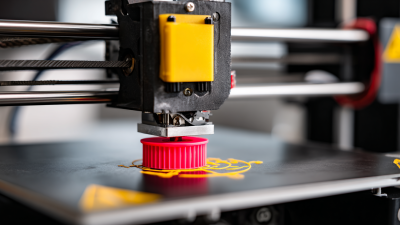

Essential Tips for Integrating 3D Printing into Your Production Line

Integrating 3D printing into your production line can significantly enhance manufacturing efficiency. According to a recent report, companies that have adopted 3D printing technologies have experienced up to a 70% reduction in lead times and a 50% decrease in material costs. This transformative approach allows for rapid prototyping, enabling manufacturers to iterate designs quickly and reduce waste significantly. In an industry increasingly shaped by artificial intelligence and the Internet of Things, the synergy created by combining these technologies with 3D printing can lead to smart, efficient production processes.

To successfully integrate 3D printing into your workflows, it is essential to evaluate your current manufacturing processes critically. Begin by identifying components that could benefit from rapid prototyping or are low-volume but high-margin. Additionally, leverage data analytics to monitor the performance of your 3D printers and optimize their operation. Embracing a modular approach allows for easy scaling and adaptation as your production needs evolve. As companies increasingly adopt these advanced technologies, staying informed about the latest trends and innovations is crucial to maintaining a competitive edge in the market.

Future Trends: 3D Printing's Impact on Manufacturing Efficiency and Cost Reduction

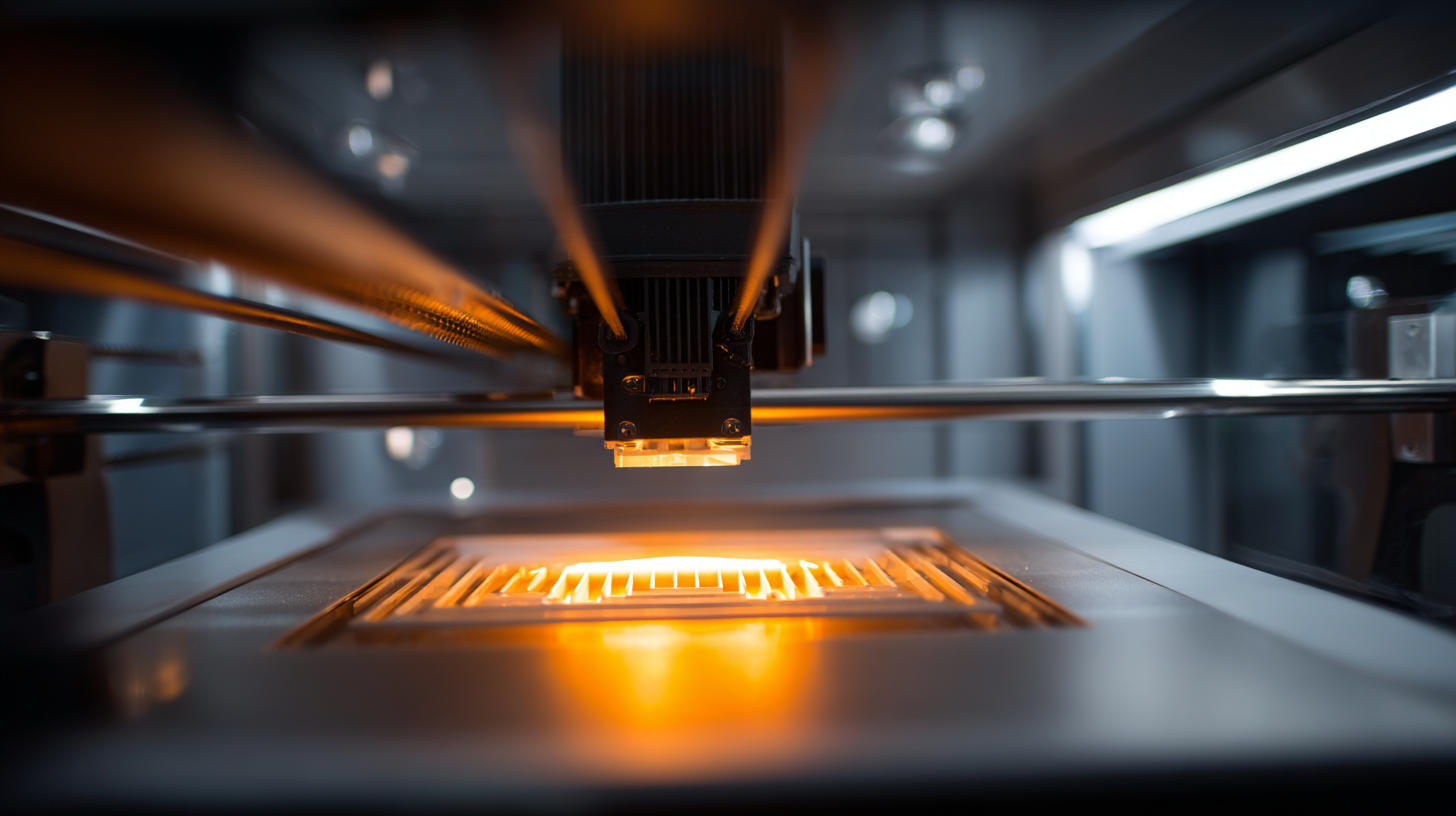

The future of manufacturing is being significantly reshaped by advancements in 3D printing technology. With the advent of specialized dental 3D printers, the market for creating dental prosthetics has witnessed a rapid expansion. The global value of this market is projected to rise dramatically from $1.543 billion in 2024 to an estimated $4.318 billion by 2033. This surge highlights the profound impact of 3D printing on efficiency and cost reduction within the dental industry, allowing for rapid prototyping and personalized solutions tailored to individual patient needs.

Moreover, the SLS (Selective Laser Sintering) 3D printer market is also experiencing robust growth, with forecasts indicating an increase from $1.353 billion in 2023 to approximately $2.812 billion by 2032. The compound annual growth rate of 8.5% reflects the increasing adoption of 3D printing technologies across various sectors, underpinning its potential to streamline manufacturing processes and reduce operational costs. As manufacturing models evolve towards greater integration of additive manufacturing, the implications for efficiency and economic viability are substantial, setting a new standard for production practices in the digital economy.

Related Posts

-

The Future of Creating Innovative Solutions with the Best 3D Machine Printer

-

Navigating Export Certifications for the Best Home 3D Printer and What You Need to Know

-

Unlocking the Secrets to the Best 3D Systems Printers for Your Business Needs

-

How to Choose the Right 3D Printer for Your Business Needs Based on Industry Trends

-

Exploring the Revolution of 3D Machine Printers for Custom Manufacturing Solutions

-

Ultimate Guide to Finding the Best Professional 3D Printer for Your Business Needs