Exploring the Revolution of 3D Machine Printers for Custom Manufacturing Solutions

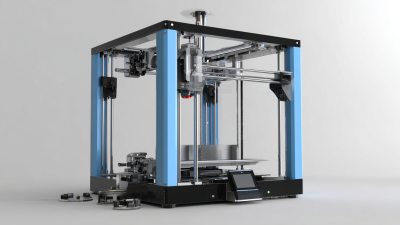

In recent years, the revolution of 3D machine printers has transformed the landscape of custom manufacturing solutions, paving the way for unprecedented innovation and creativity across various industries. As these advanced additive manufacturing technologies continue to evolve, they offer unparalleled flexibility, enabling designers and engineers to produce intricate and bespoke components that were previously unimaginable. The versatility of 3D machine printers allows for rapid prototyping, customization, and the efficient use of materials, significantly reducing waste and production time. This introduction to the world of 3D machine printers not only highlights their capacity to meet the growing demand for tailored solutions but also emphasizes their potential to disrupt traditional manufacturing processes.

As we delve deeper into this exploration, we will uncover the key benefits, applications, and future implications of integrating 3D machine printers into custom manufacturing practices.

The Transformation of Manufacturing: A Deep Dive into 3D Printing Technology

The manufacturing landscape is undergoing a remarkable transformation driven by the advancements in 3D printing technology. This innovative approach allows for the creation of complex geometries and customized designs that were once deemed impossible or too costly with traditional manufacturing methods. By utilizing additive manufacturing, companies can significantly reduce material waste and lead times, enabling a more sustainable and efficient production process. The ability to produce intricate parts on demand not only enhances flexibility but also fosters creativity within engineering and design teams.

Moreover, 3D printing is democratizing manufacturing by lowering entry barriers for small businesses and startups. With the availability of affordable 3D printers and user-friendly software, entrepreneurs can quickly prototype their ideas and bring them to market without the extensive capital investment typically required for traditional manufacturing setups. This shift empowers innovators from various industries to experiment and iterate rapidly, paving the way for groundbreaking products and solutions tailored to specific consumer needs. As 3D printing continues to evolve, it promises to redefine manufacturing practices and consumer experiences alike, showcasing the potential of customized production in a fast-paced, ever-changing economy.

Types of 3D Printing Technologies: Understanding FDM, SLA, and SLS

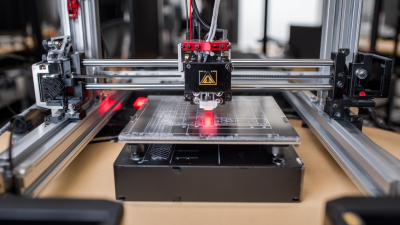

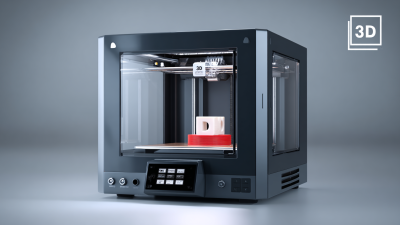

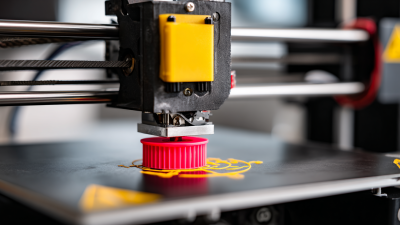

The advent of 3D printing technologies has revolutionized custom manufacturing, enabling rapid prototyping and unique designs. Among the most popular methods are Fused Deposition Modeling (FDM), Stereolithography (SLA), and Selective Laser Sintering (SLS). FDM works by melting thermoplastic filaments, making it ideal for functional prototypes and lower-cost production. Its accessibility has made it a favorite among hobbyists and small businesses alike.

SLA, on the other hand, employs a laser to cure liquid resin into hardened plastic, creating highly detailed and smooth finishes. This method is perfect for intricate designs and applications such as dental molds or jewelry prototypes. For those looking to work with metal or nylon, SLS utilizes a laser to fuse powdered materials layer by layer, offering greater strength and durability, ideal for industrial applications.

**Tips:** When choosing a 3D printing technology, consider your specific project needs—detail versus speed and cost can greatly influence your choice. Additionally, always factor in post-processing requirements, as some methods may need more cleanup than others. Exploring these technologies can lead you to find the perfect solution tailored for your manufacturing challenges.

Applications of 3D Printing in Custom Manufacturing Across Industries

The application of 3D printing in custom manufacturing has transformed various industries, particularly aerospace. At Materialise's headquarters, insights revealed how additive manufacturing serves as an "unsung hero" in the aerospace sector. This technology facilitates the production of complex geometries that are often impossible with traditional manufacturing methods. The ability to create lightweight, high-strength components not only enhances performance but also contributes to significant cost savings and faster production times.

Beyond aerospace, the impact of 3D printing extends into automotive and medical sectors, with companies leveraging advanced technologies to produce bespoke parts at scale. Innovations such as those in metal 3D printing are driving the demand for customized solutions, enabling businesses to meet specific design requirements swiftly. As the industry evolves, the widespread adoption of 3D printing will continue to revolutionize custom manufacturing, making it a pivotal player in the global market by 2030.

Advantages of 3D Printing: Cost Efficiency and Design Flexibility

The rise of 3D printing technology has fundamentally transformed custom manufacturing solutions, particularly highlighted by its cost efficiency and design flexibility. As the market for 3D printing is projected to expand significantly, reaching an estimated USD 35.79 billion by 2030 from USD 16.16 billion in 2025, industries are increasingly recognizing the pivotal advantages of additive manufacturing. This growth underlines a relentless innovation pace firsthand experienced in product prototyping, where new offerings now flutter into the market with unprecedented rapidity, often eclipsing established benchmarks.

In the construction field, the deployment of 3D-printed buildings showcases how this technology addresses pressing challenges like housing shortages while promising reduced costs and enhanced sustainability. Australia’s first multi-storey 3D-printed concrete home stands as a testament to this innovation, particularly important amid labor shortages and escalating construction expenses. Furthermore, research from various institutions indicates that 3D printing methods yield superior results for applications like headlight lens production, outperforming traditional manufacturing processes by providing enhanced precision and design versatility. Such developments not only demonstrate the flexibility of 3D printing but are also setting the stage for broader applications, potentially revolutionizing industries from construction to automotive design.

Advantages of 3D Printing in Custom Manufacturing

Challenges and Future Trends in 3D Printing for Custom Manufacturing Solutions

The landscape of custom manufacturing has been significantly transformed by the advent of 3D printing technology. However, despite its revolutionary potential, several challenges remain that hinder broader adoption in the industry. One of the primary obstacles is the material limitations associated with 3D printing. While advancements have been made in developing diverse materials, certain high-performance applications still rely on traditional manufacturing methods due to the inability to produce parts with the required mechanical properties or thermal resistance.

Moreover, the scalability of 3D printing processes poses another challenge. Most current 3D printing methods are not yet optimized for mass production, which is essential for meeting consumer demands at competitive prices. As businesses aim to implement 3D printing for custom solutions, they must navigate the complexities of integrating these technologies into existing production systems. Furthermore, the industry faces a skills gap, as the workforce requires specialized training to operate and maintain advanced 3D printing equipment. Addressing these challenges is crucial for realizing the full potential of 3D printing in custom manufacturing and ensuring its sustained growth in the future.

Related Posts

-

Ultimate Guide to Top 3D Machine Printers: A Comprehensive Comparison for Global Buyers

-

The Future of Creating Innovative Solutions with the Best 3D Machine Printer

-

Unlocking the Secrets to the Best 3D Systems Printers for Your Business Needs

-

Exploring the Industry Standards for the Best 3D Printer and Their Impact on Your Business

-

Navigating Export Certifications for the Best Home 3D Printer and What You Need to Know

-

Innovative Solutions for Optimizing Your Best 3D Printing Machine Performance