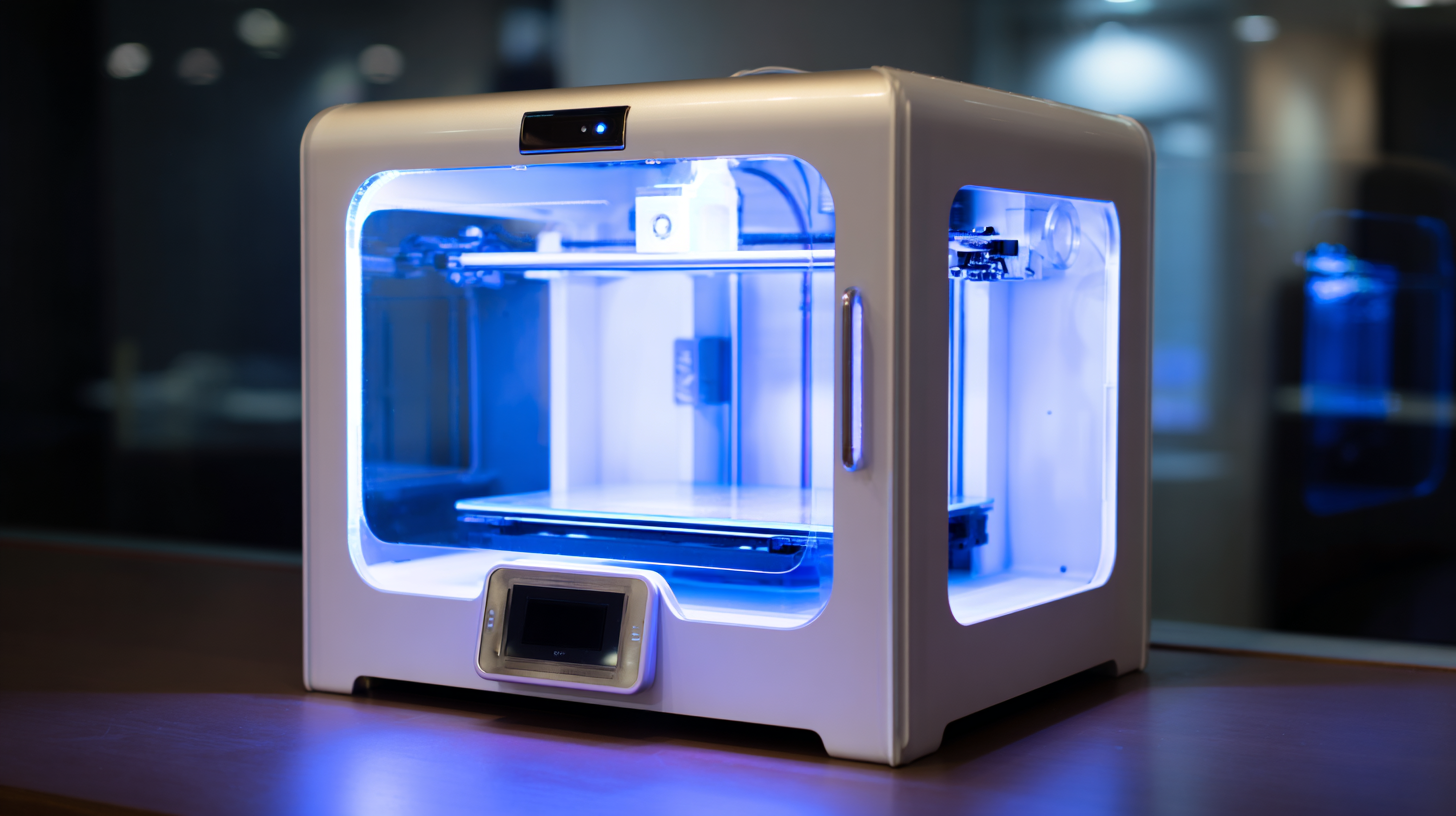

Market Forecast for High End 3D Printers in 2025 and How to Choose the Right One for Your Business

As the world embraces advanced manufacturing technologies, the demand for high end 3D printers is expected to surge by 2025, particularly in China, where top-notch manufacturing prowess has set the stage for global exports. These sophisticated machines are not only transforming traditional production methods but also enabling businesses to innovate and create customized solutions at an unprecedented scale.

However, with a plethora of options available in the market, choosing the right high end 3D printer tailored to your business needs can be a daunting task. In this blog, we will explore market forecasts for high end 3D printers, highlighting key trends and innovations, while providing insights on how businesses can effectively select the perfect machine to enhance their manufacturing capabilities and remain competitive in a rapidly evolving landscape.

Market Trends and Predictions for High-End 3D Printers by 2025

As we approach 2025, the high-end 3D printer market is set to experience substantial growth, fueled by advances in technology and increasing demand across various industries. Projections indicate that the market will witness a significant rise, reaching approximately $31.85 billion, a notable escalation from the estimated $30.52 billion in 2024. This upward trend is expected to continue, with the market potentially expanding further to $44.88 billion by 2033, highlighting the robust interest in additive manufacturing solutions.

When selecting the right high-end 3D printer for your business, several key factors should be taken into account. First, evaluate the specific applications you intend to support; different printers excel in producing various materials and resolutions. Additionally, consider the machine's scalability—does it support future expansion of your business needs? Lastly, factor in operational costs like maintenance and material supplies, as these will significantly impact the overall investment in 3D printing technology. By aligning your choices with market trends and your business objectives, you can strategically position your operations for success in this evolving landscape.

Key Features to Look for When Selecting a High-End 3D Printer

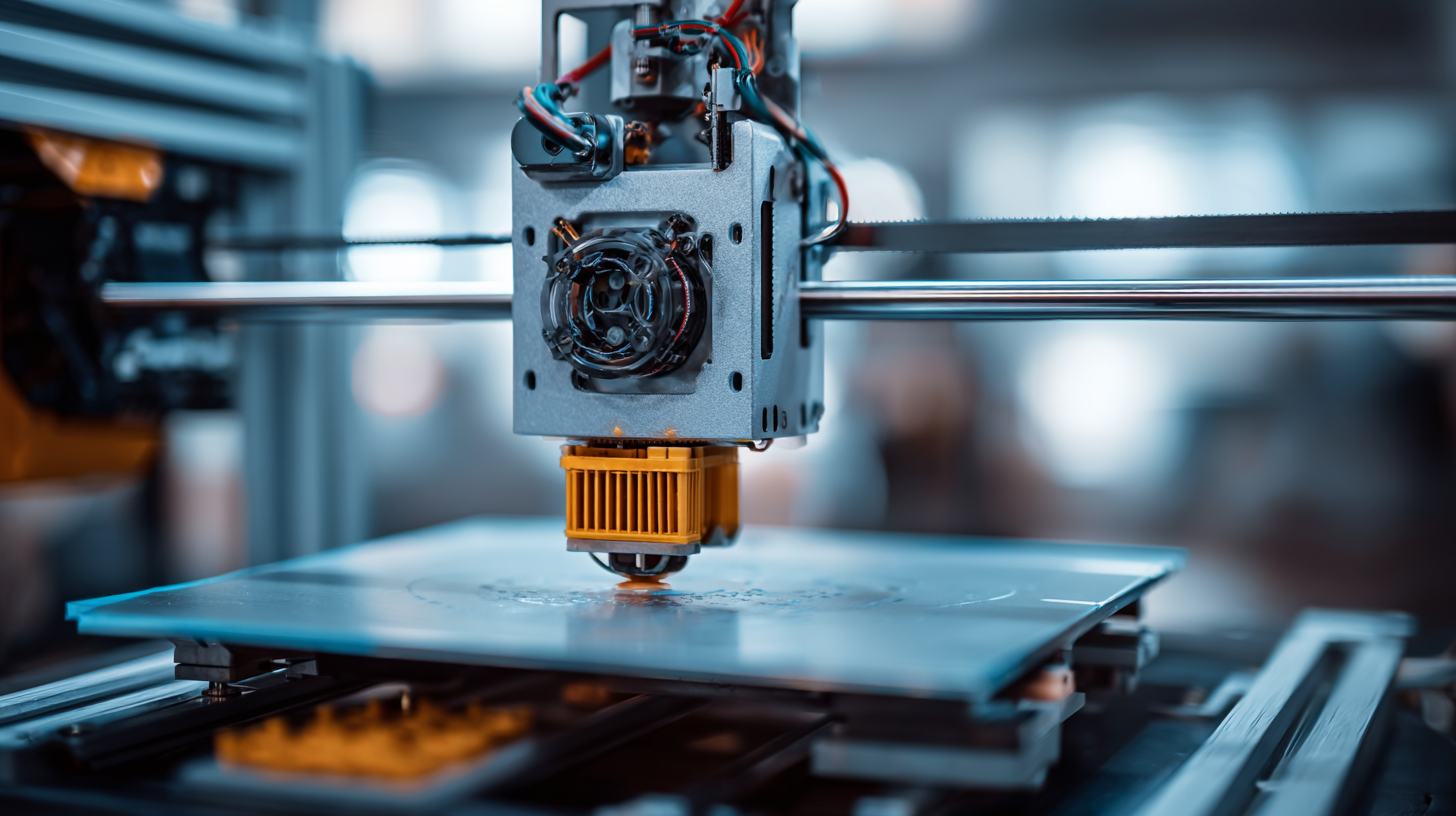

When selecting a high-end 3D printer for your business, it's crucial to focus on key features that can significantly impact your production capabilities. One of the primary factors to consider is the print resolution. High resolution ensures that your prints have fine details and smooth finishes, which is essential for applications in industries like aerospace and healthcare. Additionally, consider the build volume. A larger build volume allows for printing bigger parts or multiple items at once, enhancing efficiency.

Another important feature is the material compatibility. High-end 3D printers should support a wide range of materials, including advanced filaments and resins. This flexibility can expand your product offerings and help you cater to various customer needs. Lastly, ease of use and software integration should not be overlooked. User-friendly interfaces and compatibility with existing software can streamline your workflow and reduce operational downtime.

**Tips:** When evaluating potential printers, request a demo or sample prints to assess quality. Make sure to consider after-sales support and warranty options, as these can be invaluable in maintaining your equipment for long-term use.

Understanding the Different Types of High-End 3D Printing Technologies

The high-end 3D printing market is poised for substantial growth, with a significant demand for various printing technologies, each catering to distinct industry needs. Understanding the array of high-end 3D printing technologies is crucial for businesses looking to incorporate 3D printing into their production processes. For instance, Stereolithography (SLA) and Selective Laser Sintering (SLS) are popular for their precision and ability to create complex geometries, making them ideal for industries like aerospace and medical devices. On the other hand, Fused Deposition Modeling (FDM) is widely used for prototyping due to its cost-effectiveness and ease of use.

When selecting the right 3D printer, companies should assess their specific requirements, including print material compatibility, production speed, and part accuracy. The ability to produce functional prototypes quickly can greatly enhance a company's design iteration process. Furthermore, businesses should consider the level of technical support offered by manufacturers, as this can significantly affect the smooth operation of their printing technologies. With the market forecast predicting remarkable expansion by 2025, investing in the appropriate high-end 3D printer can set up companies for long-term success in a rapidly evolving manufacturing landscape.

Market Forecast for High End 3D Printers in 2025

| Technology Type | Estimated Market Share (%) | Key Features | Applications | Estimated Price Range (USD) |

|---|---|---|---|---|

| FDM (Fused Deposition Modeling) | 35% | Affordable, easy to use, versatile materials | Prototyping, low-volume production | $3,000 - $10,000 |

| SLA (Stereolithography) | 30% | High-resolution prints, smooth finishes | Jewelry, dental models, prototypes | $5,000 - $20,000 |

| SLS (Selective Laser Sintering) | 25% | Strong parts, no support structures needed | Functional prototypes, small batch production | $10,000 - $50,000 |

| DMLS (Direct Metal Laser Sintering) | 10% | Metal parts, intricate designs, high strength | Aerospace, automotive, medical implants | $100,000 - $1,000,000 |

| PolyJet | 5% | Multimaterial printing, high detail | Prototyping, medical models, multi-material parts | $20,000 - $200,000 |

Evaluating the Cost-Benefit Ratio of High-End 3D Printers for Your Business

When considering the acquisition of high-end 3D printers for your business, evaluating the cost-benefit ratio is crucial. High-end printers, while initially more expensive, offer advanced features such as superior print resolution, faster production speeds, and a wider range of materials. These capabilities can translate into greater efficiency and the ability to produce high-quality prototypes or products that can give your business a competitive edge. Furthermore, the longevity and durability of high-end machines often lead to lower operational costs in the long run, making them a worthwhile investment.

Additionally, it's essential to assess your specific business needs when choosing a high-end 3D printer. Factors such as the types of materials you intend to use, the desired speed and volume of production, and the complexity of your designs all play a significant role in determining the best fit for your operations. By conducting a thorough analysis of these elements alongside the upfront costs, businesses can make informed decisions that not only enhance productivity but also align with their financial strategies. In this way, you can ensure that your investment in high-end 3D printing technology truly benefits your business bottom line.

Market Forecast for High-End 3D Printers in 2025

This chart illustrates the projected increase in market value for high-end 3D printers from 2021 to 2025. By evaluating this forecast, businesses can make informed decisions regarding investment in high-end 3D printing technology.

Case Studies: Successful Implementation of High-End 3D Printers in Various Industries

High-end 3D printers are transforming various industries, driving innovation and efficiency. A recent report from Wohlers Associates highlighted that the global 3D printing market is expected to exceed $35 billion by 2025, with high-end printers playing a crucial role in this growth. For instance, in the aerospace sector, companies like Boeing have successfully implemented high-end 3D printing technologies to produce lightweight components, significantly reducing manufacturing times and costs. Boeing reported that using 3D printing can cut the weight of certain aircraft parts by 15%, enhancing fuel efficiency.

In the medical field, high-end 3D printers are revolutionizing prosthetics and implants. A study from SmarTech Analysis noted that the healthcare segment is projected to grow to $2.8 billion by 2025, with 3D printing driving personalized solutions. Companies like Materialise have been at the forefront, utilizing advanced 3D printing techniques to create customized dental implants that fit individual patient anatomies perfectly, improving patient outcomes and satisfaction.

As these case studies illustrate, selecting the right high-end 3D printer tailored to specific industry needs can yield remarkable advantages in productivity and innovation.