Why Choose a High Volume 3D Printer for Your Business?

In today's competitive market, choosing the right equipment is essential for business growth. A high volume 3D printer can be a game changer. This technology stands tall among traditional methods. It offers speed and efficiency for large-scale production. Many businesses have witnessed significant transformations with this tool.

Imagine producing hundreds of prototypes overnight. A high volume 3D printer makes this possible. It reduces lead times and enhances productivity. As a result, companies can meet market demands quickly. However, not all businesses have embraced this technology. Some may hesitate due to initial costs or technical learning curves. Investing in a high volume 3D printer requires evaluation and commitment.

Yet, the potential rewards are tempting. Enhanced capabilities lead to innovative designs and customization at scale. This is crucial in a world where consumer needs change rapidly. A business must weigh these factors carefully. Embracing a high volume 3D printer could unlock new opportunities. However, reflection on its practicality is necessary.

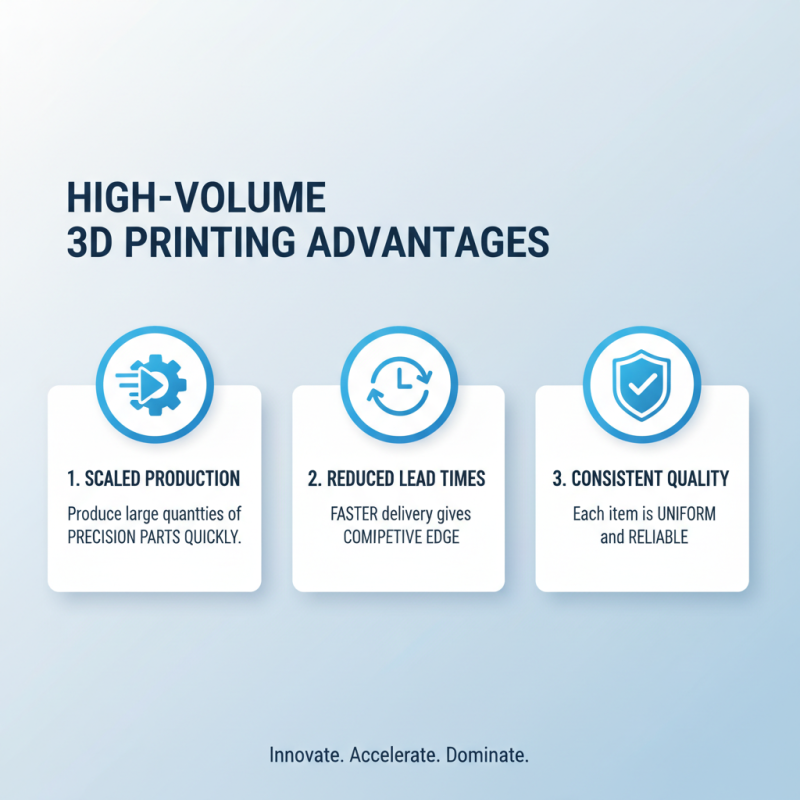

Benefits of High Volume 3D Printing for Businesses

High volume 3D printing offers significant advantages for businesses seeking to scale production. It allows companies to produce large quantities of precision parts quickly. This speed can dramatically reduce lead times, giving businesses an edge in competitive markets. More importantly, it ensures consistency in quality for each printed item.

Tips: Consider your production needs thoroughly. Identify which parts benefit most from 3D printing. Not all items require high volume production. Reflect on current workflows. Are there bottlenecks that high volume printing could alleviate?

Sustainability is also a key benefit. High volume 3D printers often use less material than traditional methods. This can lead to reduced waste and lower costs. Companies can optimize their resources better and establish a more sustainable production process. However, it's vital to assess the quality of materials used. Poor quality can lead to more waste in the long run.

Tips: Regularly evaluate the performance of your 3D printer. Are you satisfied with the output quality? Don't overlook maintenance. Keeping your machine in top shape is crucial for consistent performance.

Key Features to Look for in a High Volume 3D Printer

When considering a high volume 3D printer for your business, key features are crucial. Build size is one of the most important aspects. A larger build size means you can print bigger parts or multiple pieces at once. This can dramatically reduce production time and increase efficiency.

Print speed is another essential factor. High volume printers should have faster print speeds without sacrificing quality. Look for models that can operate continuously with minimal downtime. This is vital for businesses aiming to scale production.

Tips: Always check user reviews on print reliability. Explore technologies like dual extrusion for complex builds. Don’t overlook maintenance ease; a user-friendly design can save time and boost productivity.

Material versatility also matters. A printer that supports multiple materials can expand your design possibilities. It’s essential to evaluate whether the printer can handle different filament types. Some materials may warp or require specific conditions. This can lead to wasted resources and frustration.

Remember, select a printer that aligns with your specific needs. It's worth considering your future production goals. A model that seems perfect now might become a limitation later. Aim for flexibility to adapt as your business evolves.

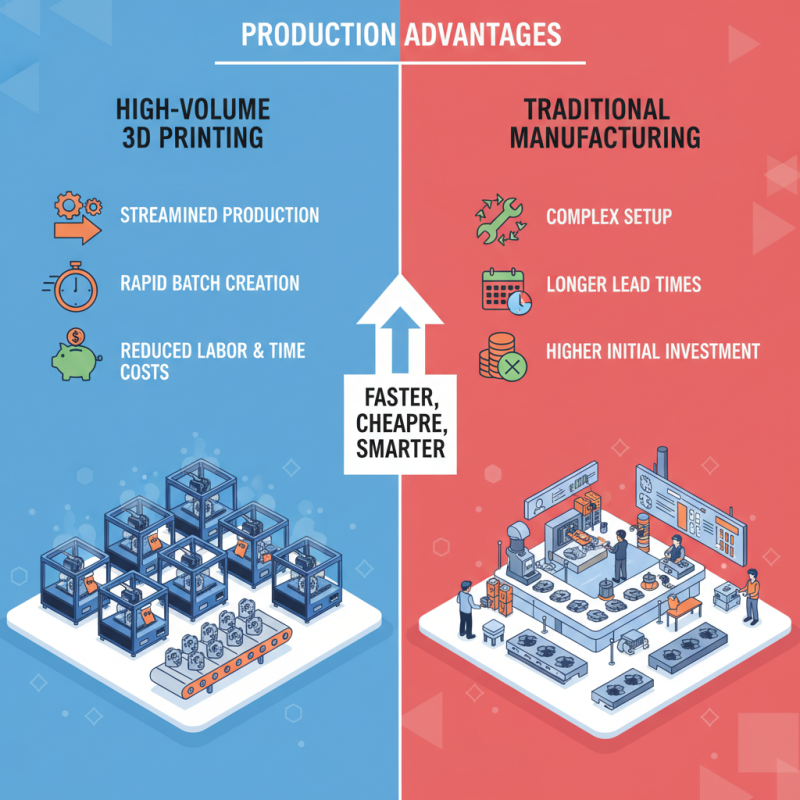

Comparing High Volume 3D Printers to Traditional Manufacturing Methods

High volume 3D printers offer unique advantages over traditional manufacturing methods. They streamline production processes. Unlike conventional methods, which often require extensive setup, 3D printing can create large batches quickly. This saves time and reduces labor costs.

For businesses, the flexibility of 3D printing is a game changer. Designers can easily modify digital files. This adaptability allows companies to respond quickly to market demands. Traditional manufacturing methods might struggle with changes, leading to delays and wasted materials.

Tips: Consider your production needs. Assess the volume and complexity of parts you require. A detailed evaluation can save costs. Also, think about material options. Different materials can affect the final product's quality and functionality. A mix of materials may enhance performance.

Remember, transitioning to 3D printing has challenges. Initial costs can be high. Staff might need training. Reflect on these factors before making a decision. Despite the hurdles, the potential for innovation is vast. Embracing 3D printing could redefine your business's future.

Cost Efficiency: Understanding the ROI of High Volume 3D Printing

Investing in a high-volume 3D printer can significantly enhance your business's cost efficiency. The return on investment (ROI) often becomes evident after just a few production runs. By reducing material waste and speeding up production times, companies can save money long-term. High-volume printers allow for the rapid creation of prototypes or end-use parts, which can streamline the manufacturing process.

Tips for maximizing ROI with 3D printing include understanding your material costs. Some materials are more economical for high-volume production. On top of that, consider the maintenance of your equipment. Regular upkeep prevents downtime, which can be costly. Predicting your production needs can also lead to better budgeting.

It's essential to reflect on the learning curve associated with new technology. Adaptation requires time and training. Ensure your team is prepared to handle this shift. Challenges will arise, and you’ll need to address them swiftly. Continuous improvement in processes will lead to better financial outcomes.

Cost Efficiency: Understanding the ROI of High Volume 3D Printing

Real-World Applications and Success Stories in High Volume 3D Printing

High volume 3D printing is transforming industries. Companies are embracing this technology for faster production rates. Customization is another key benefit. For example, in the medical field, high volume 3D printers can create patient-specific implants quickly. One company produced hundreds of surgical guides in weeks, not months. This not only saved time but also improved patient outcomes.

In the automotive sector, manufacturers are using these printers for rapid prototyping. They can experiment with designs without the long lead times of traditional methods. This has led to innovative solutions. However, challenges remain. Not all materials are suitable for high volume printing. Some require refinement to enhance strength and durability. Companies are learning to navigate these complexities to maximize their output. High volume 3D printing is certainly promising, but it still demands careful consideration.

Why Choose a High Volume 3D Printer for Your Business? - Real-World Applications and Success Stories in High Volume 3D Printing

| Application Area | Industry | Material Used | Production Volume | Notable Benefits |

|---|---|---|---|---|

| Prototyping | Automotive | PLA | 1000 units/month | Reduced time to market |

| Customized Tools | Manufacturing | Nylon | 500 units/month | Cost savings on tooling |

| Medical Devices | Healthcare | TPU | 2000 units/month | Personalized solutions |

| Architectural Models | Construction | ABS | 300 units/month | Enhanced client presentations |

| Consumer Products | Retail | PETG | 1500 units/month | Faster inventory turnover |

Related Posts

-

7 Digital Innovations Transforming the Professional 3D Printer Industry

-

Addressing Common Issues with Enclosed 3D Printers: A Comprehensive Guide

-

20 Essential Tips for Selecting the Best Professional 3D Printer

-

What is a High End 3D Printer and How It Transforms Your Creations

-

Top 10 High Volume 3D Printers for Efficient Large-Scale Production

-

Best Professional 3D Printers for Every Business Need?