What is a High Volume 3D Printer and Why is it Essential for Businesses?

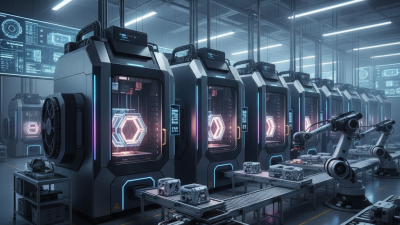

In today's rapidly evolving manufacturing landscape, businesses are constantly seeking innovative solutions to meet the demands of their production processes. One such solution that has garnered significant attention is the high volume 3D printer. These advanced machines enable companies to produce large quantities of parts and prototypes quickly and cost-effectively, making them essential tools in various industries, from automotive to aerospace and beyond. With the ability to create complex geometries and reduce material waste, high volume 3D printers not only streamline production but also enhance the overall efficiency of operations.

As industries face increasing pressure to minimize lead times and adapt to changing market needs, the importance of high volume 3D printers cannot be overstated. They empower businesses to harness the benefits of additive manufacturing, allowing for greater flexibility in design and the rapid iteration of products. This capability opens up new avenues for innovation, enabling companies to stay competitive in a fast-paced environment. By integrating high volume 3D printing into their workflows, organizations can not only meet customer demands more effectively but also drive down costs and optimize their supply chains. Thus, the high volume 3D printer emerges as a crucial asset for businesses looking to thrive in the modern economy.

What Defines a High Volume 3D Printer in Today's Market?

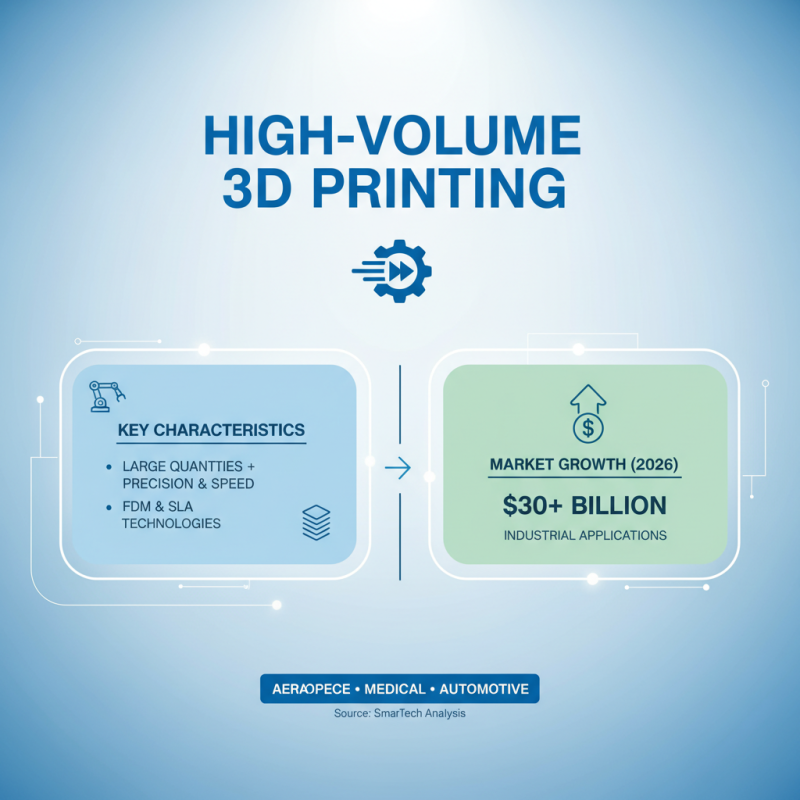

In today's rapidly evolving market, a high-volume 3D printer is characterized by its ability to produce large quantities of parts with high precision and speed. According to a recent market analysis by SmarTech Analysis, the global 3D printing market for industrial applications is expected to exceed $30 billion by 2026, with high-volume additive manufacturing solutions driving a significant portion of this growth. These printers commonly utilize advanced technologies such as Fused Deposition Modeling (FDM) and Stereolithography (SLA) to deliver consistent, repeatable results, making them ideal for industries ranging from aerospace to medical device manufacturing.

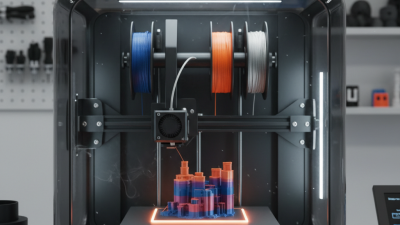

The defining features of high-volume 3D printers include larger build volumes, faster printing speeds, and enhanced material capabilities. As outlined in the 2021 Wohlers Report, the ability to print large geometries in one go not only reduces production time but also minimizes material waste—critical factors for businesses looking to optimize their manufacturing processes. Furthermore, these printers often come equipped with sophisticated software for real-time monitoring and controls, ensuring quality assurance throughout the production cycle. Ultimately, the integration of high-volume 3D printing capabilities is becoming essential for businesses aiming to maintain competitiveness and respond swiftly to market demands.

Key Benefits of High Volume 3D Printing for Modern Businesses

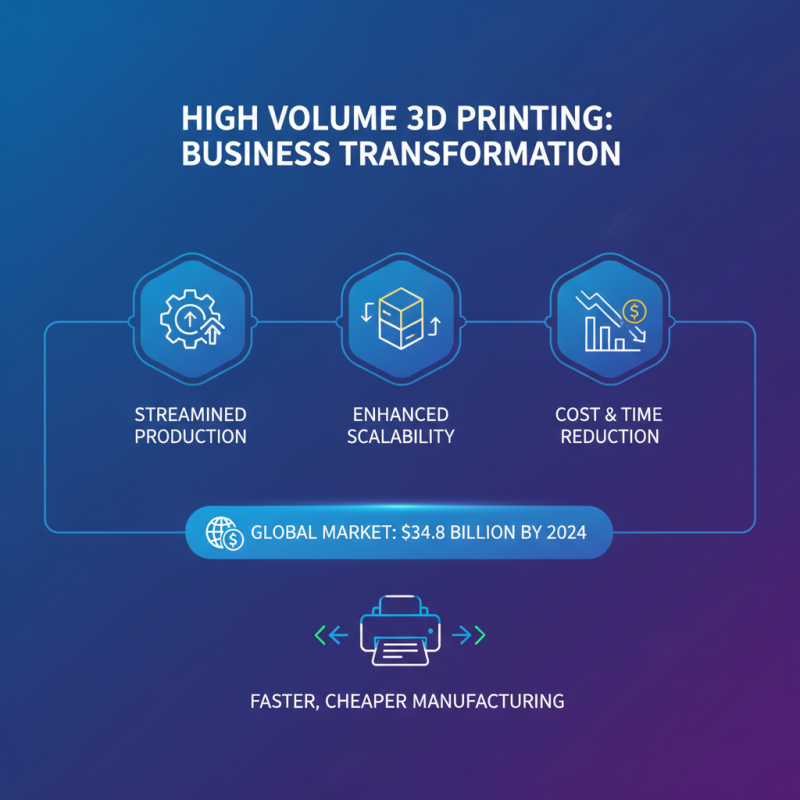

High volume 3D printing represents a transformative trend for modern businesses, enabling them to streamline production processes and enhance scalability. As reported by industry experts, the global 3D printing market is expected to reach $34.8 billion by 2024, with significant contributions from high volume technologies. These advanced printers allow companies to produce large quantities of parts in a fraction of the time and cost associated with traditional manufacturing methods.

One of the key benefits of high volume 3D printing is its ability to facilitate rapid prototyping. A study by Wohlers Associates indicates that the time-to-market for new products can be reduced by as much as 75% when utilizing high volume additive manufacturing techniques. This efficiency not only shortens development cycles but also supports the agile adaptation of products to meet shifting consumer demands, giving businesses a competitive edge in fast-paced markets.

Moreover, high volume 3D printing promotes significant cost savings. According to a recent report from Gartner, organizations that implement high volume 3D printing can cut production costs by up to 40%. This reduction is largely attributed to decreased material waste and lower labor expenses, as automated printing processes require minimal human intervention. By integrating high volume 3D printing into their operations, businesses can not only improve their bottom line but also enhance their sustainability efforts, making it a vital investment for the future.

Industry Statistics on the Growth of High Volume 3D Printing Applications

The high volume 3D printing market is witnessing remarkable growth, driven by advancements in manufacturing technologies and increasing demand across various industries. According to a report by MarketsandMarkets, the global 3D printing market is projected to reach USD 34.8 billion by 2026, growing at a compound annual growth rate (CAGR) of 23%. This surge can be attributed to the expanding applications of high volume 3D printing in sectors such as automotive, aerospace, healthcare, and consumer goods, where speed and customization are becoming essential.

Moreover, the adoption of high volume 3D printing processes is transforming traditional manufacturing paradigms. A survey conducted by Deloitte found that 61% of manufacturers expect significant growth in additive manufacturing applications in their production lines over the next few years. This transition is not only optimizing production efficiency but also reducing material waste, a key factor in sustainability efforts. As companies strive to meet the rising consumer expectations for personalized products without sacrificing production speed, high volume 3D printing stands out as an innovative solution that enables businesses to stay competitive in an evolving marketplace.

Comparative Analysis: High Volume vs. Standard 3D Printers in Production

High volume 3D printers, distinct from standard models, are designed to produce large quantities of parts within shorter timeframes. According to industry reports, high volume printers can operate 24/7, achieving production rates up to 400% faster than their standard counterparts. This efficiency makes them crucial for businesses aiming to meet increasing demand without sacrificing quality. High volume printers also offer improved material utilization, reducing waste and lowering production costs, which is essential for maintaining profit margins in a competitive landscape.

When considering high volume vs. standard 3D printers, it's vital to recognize the trade-offs in versatility and precision. While standard printers are more suited for complex designs and prototyping, high volume printers excel in producing uniform items such as components and housings. They often incorporate multiple extruders or larger build volumes, enabling businesses to manufacture more parts in a single print cycle. This comparative advantage is why industries like aerospace and automotive are increasingly adopting high volume 3D printing technologies.

Tips: When selecting a high volume 3D printer, consider your specific production needs such as the type of materials you'll use and the desired finish of the parts. Additionally, investing in a printer with advanced software capabilities can significantly enhance your workflow efficiency. Finally, don’t overlook the importance of post-processing options, as these can further improve the consistency and quality of your final products.

Production Comparison: High Volume vs. Standard 3D Printers

Future Trends in High Volume 3D Printing and Their Business Impacts

The landscape of high volume 3D printing is evolving rapidly, with several future trends that have significant implications for businesses. One of the most notable trends is the integration of advanced materials into high volume production processes. As innovative materials improve in strength, flexibility, and sustainability, companies can expand their product offerings while maintaining cost efficiency. This shift towards specialized materials not only enhances product performance but also allows businesses to meet diverse customer needs more effectively.

Moreover, AI and automation are transforming how high volume 3D printers operate. These technologies streamline production lines by optimizing printing processes and reducing human error. As a result, businesses can achieve faster turnaround times and higher productivity levels. Companies adopting these advancements will likely see a significant competitive edge, particularly in industries such as automotive and aerospace, where precision and efficiency are critical.

Tips: When considering adopting high volume 3D printing, businesses should invest in employee training to ensure all team members are proficient with the new technology. Additionally, regularly evaluate material options to stay aligned with industry advancements. This proactive approach to innovation can greatly enhance overall efficiency and product quality in the long run.

What is a High Volume 3D Printer and Why is it Essential for Businesses?

| Feature | Description | Benefits for Businesses |

|---|---|---|

| Build Volume | Large printing area to create multiple items in one run. | Increases production capabilities and reduces lead times. |

| Print Speed | Faster layer curing and material extrusion methods. | Enables rapid prototyping and quicker time-to-market. |

| Material Versatility | Compatibility with a wide range of thermoplastics and composites. | Supports a variety of applications and customizations. |

| Cost Efficiency | Reduced waste through additive manufacturing processes. | Lower production costs and improved profit margins. |

| Automation and Integration | Ability to integrate with manufacturing systems for automation. | Streamlines production workflows and enhances efficiency. |

Related Posts

-

Navigating Export Certifications for the Best Home 3D Printer and What You Need to Know

-

20 Essential Tips for Selecting the Best Professional 3D Printer

-

Market Forecast for High End 3D Printers in 2025 and How to Choose the Right One for Your Business

-

Envisioning the Future of 3D Printing: Why the Best Desktop Models Will Lead Innovation

-

Top 10 High Volume 3D Printers for Efficient Large-Scale Production

-

What is an Enclosed 3D Printer and Why You Should Consider One