Unlocking the Future of Manufacturing Through 3D Machine Printing Innovations and Industry Transformations

In an era marked by rapid technological advancements, the manufacturing industry stands at the precipice of a revolutionary shift driven by the innovations in 3D machine printing. As industry experts note, the integration of 3D machine printers into production processes not only enhances efficiency but also fosters unprecedented creativity in design and material usage. Renowned figure in additive manufacturing, Dr. Jennifer Lewis, states, "3D machine printing is not just a tool; it is a transformative force that is reshaping how products are conceived and realized."

With the emergence of sophisticated 3D machine printers, manufacturers are finding opportunities to streamline operations while reducing material waste and costs. The ability to produce complex parts on demand eliminates the traditional constraints associated with mass production, allowing for greater customization and flexibility in the market. As we delve into the top five innovations and transformations within the 3D machine printing domain, it becomes clear that these advancements are not merely technological; they represent a paradigm shift in how industries will adapt to meet future challenges.

The potential of 3D machine printing extends beyond the confines of traditional manufacturing, touching various sectors including aerospace, healthcare, and automotive. As we unlock the future of manufacturing, it is essential to explore these breakthroughs and understand how they will redefine the landscape of production and supply chains in the years to come.

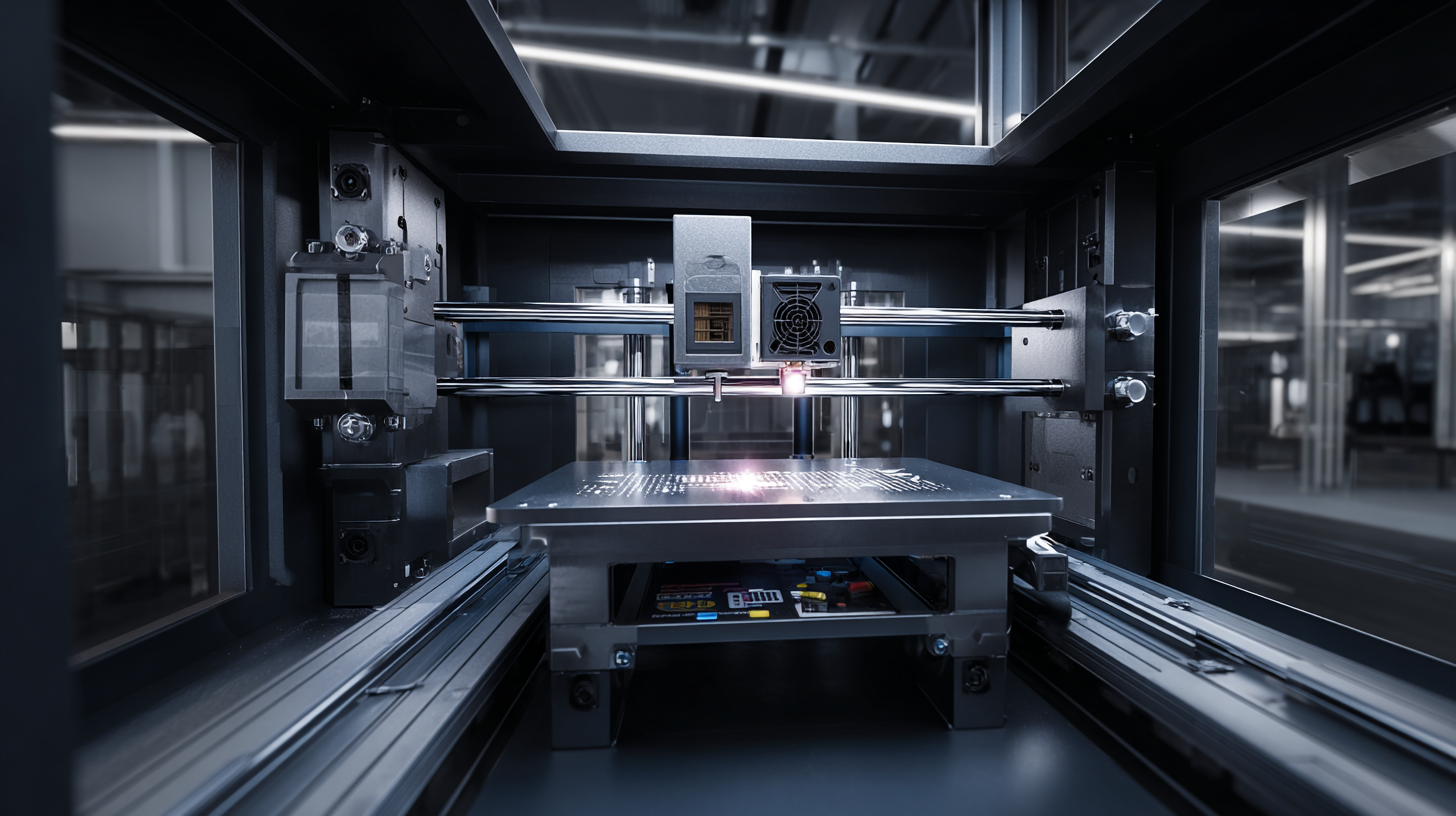

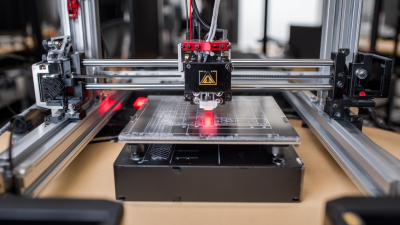

The Rise of 3D Machine Printing in Modern Manufacturing

The rise of 3D machine printing in modern manufacturing marks a transformative shift in how products are designed and produced. According to a report by Wohlers Associates, the global 3D printing market was valued at approximately $12.6 billion in 2020 and is projected to reach $34.8 billion by 2026, growing at a compounded annual growth rate (CAGR) of 22.5%. This rapid expansion highlights the increasing acceptance of additive manufacturing techniques across various sectors, including aerospace, automotive, and healthcare.

One of the key benefits driving this growth is the technology's ability to streamline production processes, reduce waste, and enable rapid prototyping. For instance, a study from the Boston Consulting Group found that companies adopting 3D printing can reduce the cost of traditional manufacturing methods by up to 50% in certain applications. This capability not only enhances efficiency but also encourages innovation, as design teams can quickly iterate on prototypes and bring products to market faster than ever before. As manufacturing continues to embrace these advancements, the capabilities of 3D machine printing will undoubtedly unlock new opportunities for businesses and reshape the future of the industry.

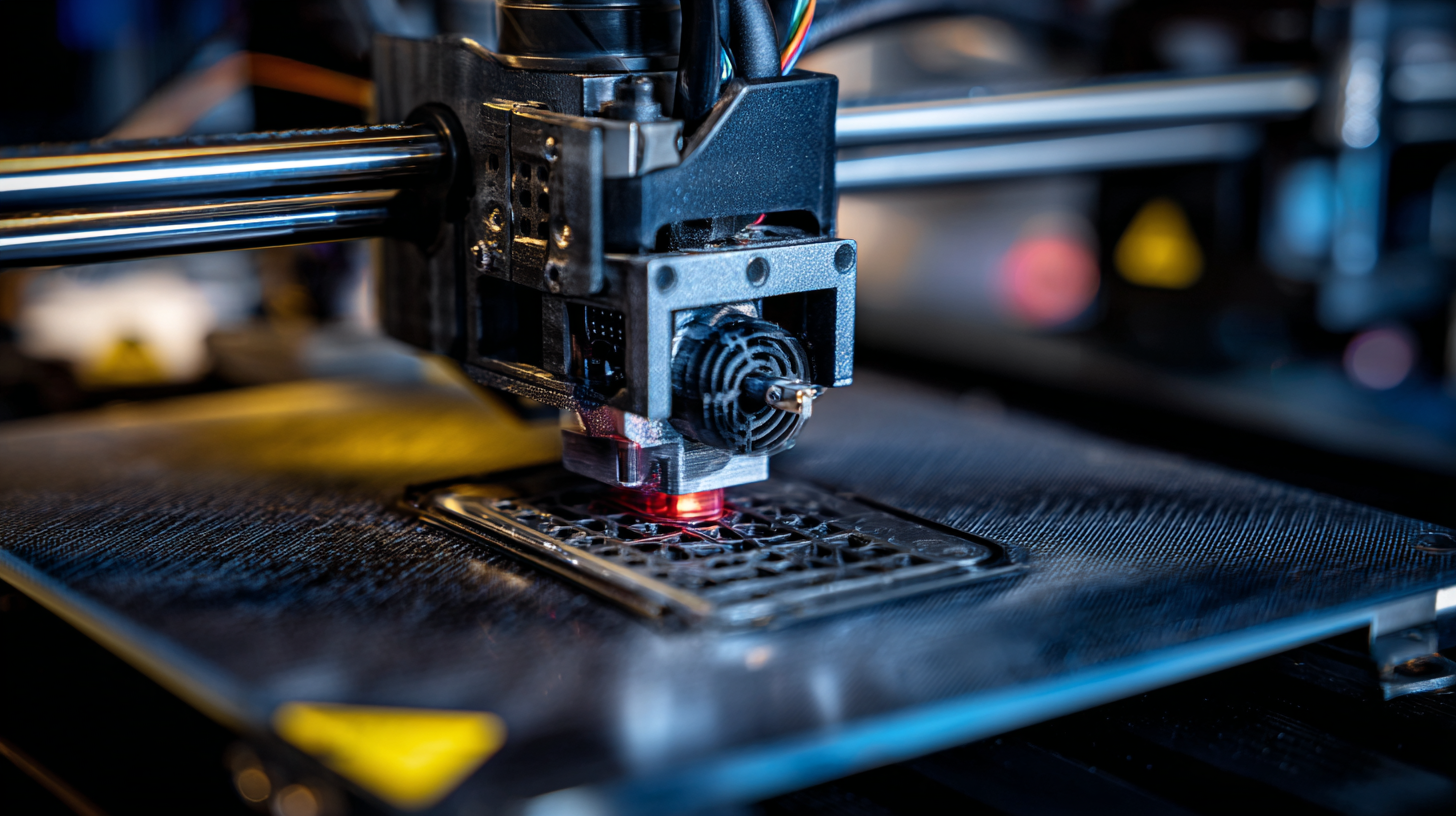

Key Innovations Revolutionizing the Manufacturing Process

The manufacturing landscape is undergoing a profound transformation with the advent of 3D machine printing innovations. These technologies not only streamline production processes but also allow for unprecedented design flexibility. One of the critical innovations is the use of advanced materials such as composites and bio-materials, which enhance product performance while reducing waste. This capability enables manufacturers to create complex geometries that were once deemed impossible, pushing the boundaries of traditional manufacturing.

**Tip:** When considering 3D printing for your manufacturing needs, evaluate the specific materials and technologies that align with your product requirements. Investing in the right capabilities from the beginning can save both time and resources in the long run.

Another exciting development is the integration of smart manufacturing techniques with 3D printing. Utilizing data analytics and IoT (Internet of Things) technology enables manufacturers to optimize production schedules and predict maintenance needs. This synergy not only maximizes efficiency but also reduces downtime, leading to quicker turnaround times for customers.

**Tip:** Keep an eye on industry trends related to smart manufacturing. Integrating data-driven decision-making into your operations can enhance productivity and provide a competitive edge in the rapidly evolving market.

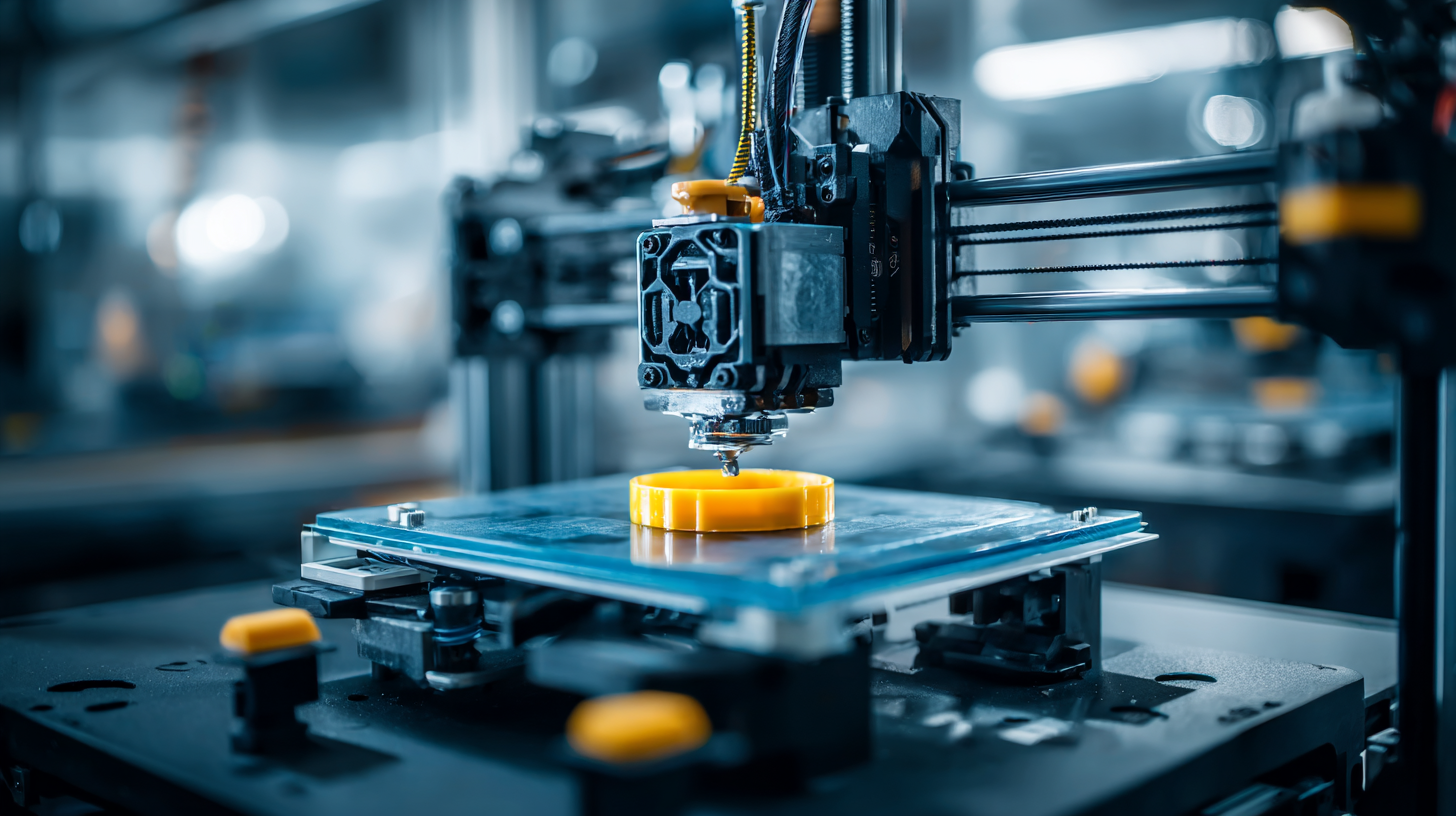

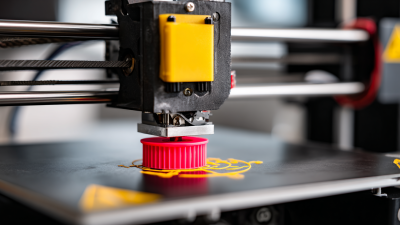

Impact of 3D Printing on Supply Chain Dynamics

The advent of 3D printing technology has significantly transformed supply chain dynamics across various sectors. According to a report by Gartner, the global 3D printing market is expected to reach $34.8 billion by 2024, reflecting a CAGR of 23.5%. This rapid growth indicates that manufacturers are increasingly adopting 3D printing not just for prototyping, but for mass production of components, enabling them to respond swiftly to market changes while reducing lead times.

One of the most profound impacts of 3D printing on supply chains is the shift towards localized production. By allowing manufacturers to produce parts closer to the end-user, transportation costs and lead times can be drastically reduced. A study by Deloitte estimates that 3D printing could reduce supply chain costs by as much as 30% while improving product customization. This level of flexibility means businesses can adapt their supply strategies more efficiently, leading to greater resilience and competitiveness in today’s fast-paced market. The integration of 3D printing into supply chains not only fosters innovation but also creates opportunities for sustainable practices, promoting a circular economy model where waste is minimized and resources are reused effectively.

Impact of 3D Printing on Supply Chain Dynamics

Sustainability Benefits of Additive Manufacturing Techniques

The sustainability benefits of additive manufacturing (AM) techniques are gaining recognition as the industry shifts towards greener practices. According to a report by the Ellen MacArthur Foundation, transitioning to a circular economy could yield a reduction of up to 70% in raw material consumption within the manufacturing sector.  3D printing minimizes waste by employing a layer-by-layer production method, which uses only the material necessary for the final product. This reduction in waste aligns with global sustainability goals and helps companies meet regulatory standards while improving their environmental footprint.

3D printing minimizes waste by employing a layer-by-layer production method, which uses only the material necessary for the final product. This reduction in waste aligns with global sustainability goals and helps companies meet regulatory standards while improving their environmental footprint.

Another notable advantage of AM is its ability to localize production, thereby reducing transportation emissions. A study by Wohlers Associates highlights that localized 3D printing can decrease supply chain costs and lead times significantly, as products can be manufactured closer to the end users. Additionally, the customization capability of 3D printing allows for products to be tailored to specific needs, further reducing excess inventory and waste.

Tips: To maximize the sustainability benefits of 3D printing, manufacturers should invest in training their workforce on AM technologies and best practices. Regularly reviewing and optimizing the materials used in the printing process can also lead to significant reductions in waste and energy consumption. Lastly, sharing insights and strategies with industry peers can foster a collaborative approach to sustainability, driving innovation across the sector.

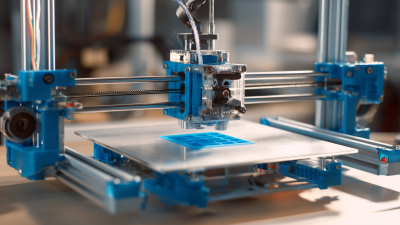

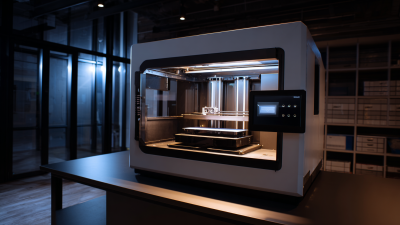

Future Trends: What’s Next for 3D Machine Printing in Industry?

The future of 3D machine printing is poised for significant advancements, driven by continuous innovations and evolving industry needs. The SLS (Selective Laser Sintering) 3D printing market, valued at $1.353 billion in 2023, is expected to reach $2.8118 billion by 2032, reflecting a robust compound annual growth rate (CAGR) of 8.5%. This growth indicates a promising trend where companies increasingly adopt 3D printing technologies to enhance production efficiency and reduce costs.

As industries recognize the advantages of 3D printing, such as rapid prototyping and customization, the technology is likely to find applications beyond traditional manufacturing. Emerging sectors, including medical devices, aerospace, and automotive, are expected to become major beneficiaries of these innovations.

The integration of advanced materials and smart manufacturing processes will further unlock new possibilities, allowing for greater design freedom and improved product functionality, indicating that the trajectory of 3D machine printing will continue to reshape the landscape of modern manufacturing in the years to come.

Related Posts

-

Exploring the Revolution of 3D Machine Printers for Custom Manufacturing Solutions

-

Ultimate Guide to Top 3D Machine Printers: A Comprehensive Comparison for Global Buyers

-

Revolutionizing Prototyping: How 3D Systems Printers Are Transforming Manufacturing Efficiency

-

Unlocking the Secrets to the Best 3D Systems Printers for Your Business Needs

-

The Future of Creating Innovative Solutions with the Best 3D Machine Printer

-

Navigating Export Certifications for the Best Home 3D Printer and What You Need to Know