The Future of Creating Innovative Solutions with the Best 3D Machine Printer

The emergence of the 3D machine printer has revolutionized the landscape of product design and manufacturing, providing unprecedented opportunities for innovation across various industries. According to a report by SmarTech Analysis, the global 3D printing market is projected to reach $34.8 billion by 2024, expanding at a CAGR of over 25%. This growth reflects the increasing adoption of 3D printing technology in sectors such as aerospace, healthcare, and automotive, where rapid prototyping and custom solutions are critical. The ability to create complex designs with reduced production time and cost has made the 3D machine printer an essential tool for engineers and designers. As we delve into the technical specifications that define these machines and explore practical applications, we will uncover how they can pave the way for future innovations, ultimately reshaping the manufacturing landscape and enhancing productivity.

The Evolution of 3D Printing Technology: A Key Driver for Innovation

The rapid evolution of 3D printing technology has positioned it as a key driver for innovation across various industries. According to a report from MarketsandMarkets, the global 3D printing market is expected to reach $34.8 billion by 2024, reflecting a compound annual growth rate (CAGR) of 21%. This explosive growth highlights the increasing reliance on 3D printing for producing innovative solutions that were previously unimaginable. As the technology continues to advance, we see significant improvements in materials, speed, and precision, making 3D printing an integral part of product development and prototyping.

Tip: To harness the full potential of 3D printing, businesses should invest in employee training programs that focus on design software and printing techniques. This empowerment is essential for driving creative solutions and maximizing the value derived from 3D printing technologies.

Moreover, with the advent of new materials like carbon fiber and bio-materials, industries are opening doors to sustainable and durable products. A report by Wohlers Associates indicates that 3D printing could reduce material waste by up to 90%, presenting a compelling case for its adoption in environmentally conscious manufacturing.

Tip: Companies looking to innovate should keep an eye on emerging trends and technologies in 3D printing, as staying ahead of the curve can facilitate quicker adaptation and greater competitiveness in their respective markets.

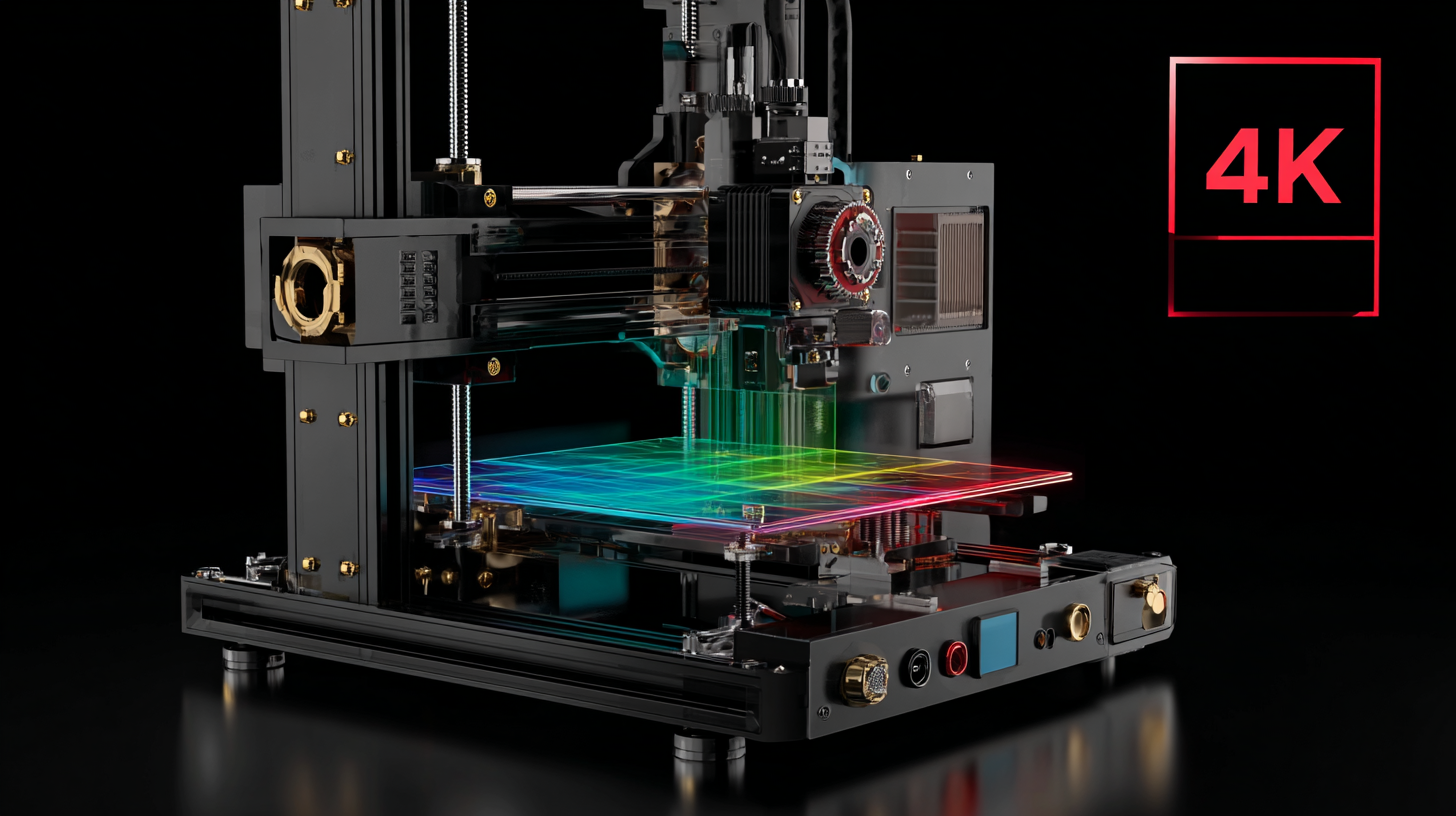

Understanding the Different Types of 3D Printers and Their Unique Features

3D printing technology has revolutionized the way we approach innovation, providing endless possibilities for creating unique solutions across various industries. Understanding the different types of 3D printers is crucial for harnessing their potential. Fused Deposition Modeling (FDM) printers, for instance, are widely popular due to their affordability and ease of use. They work by extruding thermoplastic filaments layer by layer, making them ideal for prototyping and producing functional parts.

On the other hand, Stereolithography (SLA) printers offer high precision and smooth finishes, utilizing a laser to cure liquid resin into solid layers. This technology is perfect for detailed models and intricate designs, often found in industries such as jewelry and dentistry. Lastly, Selective Laser Sintering (SLS) printers employ a laser to fuse powdered materials, enabling the creation of complex geometries that would be impossible with traditional manufacturing methods. By exploring these various printer types and their unique features, innovators can select the right tools to bring their groundbreaking ideas to life.

Exploring the Applications of 3D Printing Across Various Industries

3D printing technology is rapidly becoming a cornerstone in various industries, from healthcare to manufacturing. In the medical field, it enables the creation of customized implants and prosthetics, enhancing patient outcomes. Furthermore, innovative bioprinting techniques allow for the development of tissues and organ models, paving the way for breakthroughs in regenerative medicine. In manufacturing, 3D printing streamlines production processes, reducing waste and allowing for rapid prototyping, which significantly speeds up the development cycle of new products.

**Tip:** When implementing 3D printing in your business, consider starting with a small project that allows you to test the technology and understand its potential without overwhelming your resources.

In the aerospace sector, 3D printing is revolutionizing the way aircraft components are designed and produced. Lightweight parts that are both durable and efficient can be printed on-demand, trimming down manufacturing times and costs. The automotive industry also benefits from this technology, using it for everything from parts testing to creating intricate designs that previously would have required complex assembly.

**Tip:** Foster collaboration across departments to explore innovative applications of 3D printing and leverage insights from different perspectives to maximize its potential in your projects.

The Applications of 3D Printing Across Various Industries

Comparative Analysis: FDM, SLA, and SLS 3D Printing Methods

The 3D printing market is experiencing remarkable growth driven by technological advancements and the rising demand for personalized and complex solutions. This evolution in manufacturing is largely attributed to the emergence of various printing methods, which include Fused Deposition Modeling (FDM), Stereolithography (SLA), and Selective Laser Sintering (SLS). Each of these technologies brings unique advantages to the table—FDM is celebrated for its affordability and ease of use, while SLA provides exceptional resolution, and SLS excels in producing durable and functional parts.

A comparative analysis of these printing methods showcases the diverse applications across industries. FDM is often the go-to choice for prototyping and educational purposes, while SLA is preferred for intricate designs in sectors like jewelry and dental. SLS, on the other hand, is revolutionizing aerospace and automotive industries with its ability to create lightweight and robust components. As these technologies continue to mature, the potential for innovation in creating tailored solutions is boundless, paving the way for a new era in manufacturing that aligns with the future's demand for customization and efficiency.

Future Trends in 3D Printing: What to Expect in Coming Years

The future of 3D printing holds immense potential, with the global market projected to soar from $23.41 billion in 2025 to $100.17 billion by 2032, reflecting a remarkable compound annual growth rate of 23.4%. As industries increasingly adopt this innovative technology, we can expect to see significant advancements in 3D printed materials and applications. Leaders in the field are emphasizing the need to diversify and innovate, highlighting the importance of staying ahead of trends to leverage new opportunities.

**Tips:** Consider exploring partnerships with tech companies to enhance the integration of AI in 3D printing processes. Automating preparation and printing tasks can streamline production and reduce errors. Additionally, focus on developing eco-friendly materials to meet growing environmental concerns, as sustainability becomes a crucial factor in consumer preferences.

As we look towards 2025 and beyond, the rise of polymer materials for 3D printing is notable. The market for these materials is expected to reach $6.68 billion by 2032, with a compound annual growth rate of 13.15%. This trend showcases the shift towards more specialized and diverse applications, encouraging businesses to invest in research and development to remain competitive. Embracing these innovations will be key to thriving in the evolving 3D printing landscape.

The Future of Creating Innovative Solutions with the Best 3D Machine Printer

| Dimension | Trend | Expected Impact | Year of Expected Change |

|---|---|---|---|

| Material Usage | Biodegradable Materials | Reduction of plastic waste | 2025 |

| Technology | Metal 3D Printing | Increased production of complex parts | 2024 |

| Applications | Healthcare Solutions | Custom prosthetics and implants | 2026 |

| Market Growth | Personal 3D Printers | Rise in home manufacturing | 2023 |

| Software Integration | AI and Automation | Enhanced design and efficiency | 2025 |