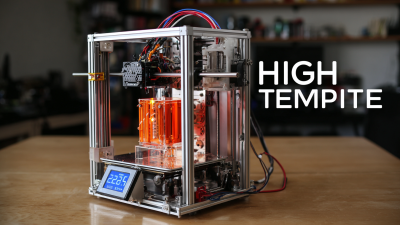

10 Essential Tips for Mastering High Temperature 3D Printing Success

As the demand for advanced manufacturing techniques grows, high temperature 3D printers are becoming indispensable tools in various industries, including aerospace, automotive, and medical sectors. According to a report by SmarTech Analysis, the market for high-temperature materials in 3D printing is projected to reach USD 1.3 billion by 2025, reflecting a compound annual growth rate (CAGR) of over 25% from 2020 to 2025. This significant growth highlights the increasing adoption of high performance polymers and composites that can withstand extreme conditions.

However, mastering the nuances of high temperature 3D printing requires a strategic approach to ensure successful outcomes. In this blog, we will explore 10 essential tips that will help you harness the full potential of your high temperature 3D printer, enabling you to produce robust and precise parts that meet the stringent demands of today's engineering challenges.

Understanding the Unique Challenges of High Temperature 3D Printing

High temperature 3D printing presents unique challenges that require a nuanced understanding of materials and processes.

Unlike traditional printing methods, high temperature 3D printing involves materials that can endure substantial thermal stress, making it essential to choose the right materials that not only adhere well but also retain their mechanical properties at elevated temperatures.

This can significantly impact the print quality and the durability of the final product.

Recent advancements highlight the importance of these considerations. In a notable application, innovative digital manufacturing techniques have enabled the creation of complex components for cutting-edge aerospace designs.

By utilizing advanced printing technology, engineers were able to produce 21 hardware components for an aircraft, showcasing how precision and reliability in high temperature 3D printing can lead to groundbreaking developments in industries where failure is not an option.

Understanding and mastering the intricacies of high temperature 3D printing can open up new frontiers in manufacturing and design, where performance and resilience are paramount.

Selecting the Right Materials for Enhanced Performance

When it comes to high-temperature 3D printing, selecting the right materials is crucial for achieving enhanced performance and durability. High-temperature thermoplastics, like PEEK, ULTEM, and Nylon, are designed to withstand extreme conditions without compromising the structural integrity of your prints. Each of these materials offers unique benefits; for example, PEEK offers exceptional mechanical properties and chemical resistance, while ULTEM is known for its excellent thermal stability and dimensional accuracy. Understanding the specific requirements of your application will guide you in choosing the most suitable material.

Additionally, consider the printing process and the equipment available when selecting your materials. Not all 3D printers are equipped to handle high-temperature filaments, so it’s essential to match your material choice with a compatible printer that can reach the necessary print temperatures. This harmony between material and machinery not only enhances print quality but also ensures optimal adhesion, reducing the risk of warping or delamination. Thorough testing and experimenting with different combinations can lead to discovering the material that best meets your project’s demands, ensuring reliable and robust outcomes.

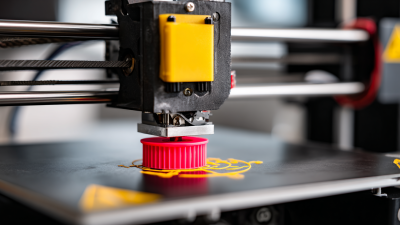

Optimizing Printer Settings for High Temperature Filaments

When it comes to high temperature 3D printing, optimizing printer settings is crucial for achieving successful prints. One of the first adjustments you should make is to increase the nozzle temperature. High temperature filaments, such as polycarbonate or nylon, require higher extrusion temperatures to ensure proper flow and adhesion. Start by consulting the filament manufacturer's recommendations, and incrementally increase the temperature until you find the sweet spot that yields smooth extrusions and a clean finish.

In addition to temperature, bed adhesion is another critical factor. High temperature filaments can be prone to warping, making it essential to use the right build surface and adhesive. A heated bed set to the appropriate temperature not only helps maintain a stable first layer but also increases the chances of successful layer adhesion throughout the print. Experiment with different surfaces like glass or PEI and consider using adhesives like PVA glue or specialized sprays to enhance grip. By meticulously tweaking these settings, you’ll pave the way for a more reliable and successful high temperature 3D printing experience.

High Temperature 3D Printing - Material Performance Comparison

Implementing Effective Cooling Strategies During Printing

Effective cooling strategies are crucial for achieving success in high temperature 3D printing. As filament materials such as nylon and polycarbonate require elevated extrusion temperatures, managing temperature control during the printing process can make a significant difference in print quality. According to a study by 3D Printing Industry, improper cooling can lead to warping and layer adhesion issues in prints, which can reduce structural integrity by up to 30%.

One practical tip is to utilize active cooling systems, such as part cooling fans or external cooling rigs, to maintain optimal temperatures. Aim for a targeted airflow of 20–30 CFM for the cooling requirements, as reported by the Journal of Additive Manufacturing. This helps prevent overheating and ensures even temperature distribution throughout the print.

Another effective strategy is to adjust the print speed and layer height accordingly. Slower printing speeds allow for better cooling between layers, helping maintain dimensional accuracy. Research indicates that decreasing the print speed by 20% can improve layer bonding and reduce warping issues significantly. By implementing these cooling strategies, you can enhance the overall performance and reliability of your high temperature 3D prints.

Post-Processing Techniques to Achieve Ideal Finishes and Strength

Post-processing plays a crucial role in achieving optimal finishes and enhanced strength in high-temperature 3D printing. Techniques such as sanding, polishing, and chemical smoothing are essential to refine the surface quality of printed parts. A study published by the Additive Manufacturing journal indicates that proper post-processing can improve the tensile strength of nylon-based materials by up to 30%. This enhancement is critical for applications in aerospace and automotive sectors, where mechanical integrity is paramount.

In addition to traditional methods, heat treatment and annealing processes are increasingly being adopted to relieve internal stresses and enhance material properties. According to research from the Journal of Materials Science, parts subjected to post-annealing exhibit significant improvements in dimensional stability and impact resistance. For instance, polyether ether ketone (PEEK) samples saw a 40% increase in fracture toughness post-annealing. By incorporating these post-processing techniques, manufacturers can ensure that their high-temperature 3D printed components not only meet but exceed industry standards for durability and performance.

Related Posts

-

7 Essential Tips for Choosing the Best High Temperature 3D Printer

-

Market Forecast for High End 3D Printers in 2025 and How to Choose the Right One for Your Business

-

Unlocking the Future: Top 5 Digital Innovations in High-End 3D Printing

-

Ultimate Guide to Choosing the Best Enclosed 3D Printer for Your Business Needs

-

Ultimate Checklist for Choosing the Best Enclosed 3D Printer for Your Business Needs

-

Navigating Export Certifications for the Best Home 3D Printer and What You Need to Know