10 Essential Tips for Choosing the Best 3D Printing Machine for Your Needs?

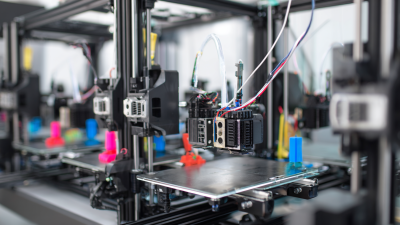

As the world of manufacturing evolves, the demand for a reliable 3D printing machine is on the rise. Industry expert Dr. Lisa Martinez, a leading figure in 3D printing technology, once stated, "The right 3D printing machine can revolutionize your creative process and production efficiency." This highlights the importance of making a well-informed choice when selecting a printer that meets your specific needs.

Choosing the right 3D printing machine involves understanding your goals and capabilities. It’s not simply about price; consider features like material compatibility, build size, and resolution. Each machine has its strengths and weaknesses. Sometimes, a high-end model may not suit your project. Reflecting on your experiences with different technologies can also guide your decision-making.

Mistakes in selection can lead to frustration. For instance, purchasing a machine ill-equipped for your projects can waste both time and resources. Awareness of your unique requirements and thorough research can help prevent these pitfalls. By considering these factors, you can find a 3D printing machine that not only meets your expectations but also enhances your work.

Understanding Your 3D Printing Requirements: Applications and Materials

When choosing a 3D printing machine, understanding your needs is crucial. Start by identifying your applications. Are you creating prototypes, models, or functional parts? Each use demands different materials and precision levels. For example, prototypes may need quick prints, while end-use products require durability.

Next, consider the materials you'll be using. Plastics, metals, and resin each have unique properties. Plastics are versatile and widely used, but they may lack strength. Resins can provide fine details but may not be suitable for large prints. Metal is strong, yet often requires specialized equipment and technology. Reflect on your specific requirements and limitations.

Finally, think about your skill level. Some machines are user-friendly, ideal for beginners. Others offer advanced features suitable for experts. Choosing a machine that matches your skills will prevent frustration down the line. Being aware of your capabilities will help you select the right tool for your projects.

10 Essential Tips for Choosing the Best 3D Printing Machine for Your Needs

| Feature | Description | Recommended for |

|---|---|---|

| Print Volume | The maximum dimensions of the objects you can print. | Large models, prototypes |

| Material Compatibility | Types of materials the printer can use (e.g., PLA, ABS, resin). | Diverse applications, different needs |

| Print Speed | How quickly the printer can produce items. | Rapid prototyping |

| Layer Resolution | The thickness of each layer of material. | Fine detail requirements |

| User Interface | Ease of use and navigation options available. | Beginners, educational use |

| Price | Total cost and budget considerations for the machine. | Hobbyists, professionals on a budget |

| Support and Community | Availability of support and resources for troubleshooting. | All users |

| Safety Features | Features that ensure safe operation of the printer. | Educational institutions, home use |

| Portability | Weight and ease of moving the machine. | Traveling professionals, demos |

| Connectivity Options | Ways to connect the printer (USB, Wi-Fi, Ethernet). | Tech-savvy users, networked environments |

Key Features to Look for in a 3D Printing Machine: A Technical Overview

When selecting a 3D printing machine, key features can significantly impact your experience. It's vital to focus on print volume, accuracy, and material compatibility. A report from Market Research Future highlights that nearly 40% of users prioritize print size when choosing a printer. Larger machines allow for larger projects, which can be essential for specific applications.

Look for the resolution specifications, often measured in microns. Lower microns indicate finer detail. A printer capable of achieving 50 microns can produce highly intricate designs. Remember, while high resolution is important, it might lead to slower print times. Balance is crucial.

Consider software compatibility as well. Some machines offer user-friendly interfaces. Others may require technical expertise. A user survey showed that 35% of users faced challenges with complex software. This can be frustrating and affect your workflow. Always test the software if possible.

In your decision-making, think about the intended use. Will you be printing prototypes, functional parts, or artistic pieces? Each requires different capabilities. Reflect on your needs and the trade-offs of each feature.

Comparing Different 3D Printing Technologies: FDM, SLA, and SLS Explained

When choosing a 3D printing machine, understanding different technologies is crucial. Fused Deposition Modeling (FDM) is the most common. It heats thermoplastic filaments to create layers. This method is generally affordable and user-friendly. However, the surface finish may not be the best. You might notice stringing or minimal detail in complex designs. It's great for prototypes, but not perfect for high-detail models.

Stereolithography (SLA) offers higher detail. It uses a resin that hardens with UV light. This process creates smooth finishes and intricate details. Yet, SLA printers can be costly and messy. Resins may have unpleasant odors and require careful handling.

You might struggle with post-processing, as models need curing and often support removal.

Selective Laser Sintering (SLS) is another option. It uses laser technology to fuse powder materials. This method creates durable parts with complex geometries. However, SLS printers tend to be the most expensive. Supplies can also be costly. There's a steep learning curve to master this technology. Each type of 3D printing has its flaws and advantages, requiring careful consideration of your specific needs.

Budget Considerations: Cost of Ownership vs. Initial Investment in 3D Printers

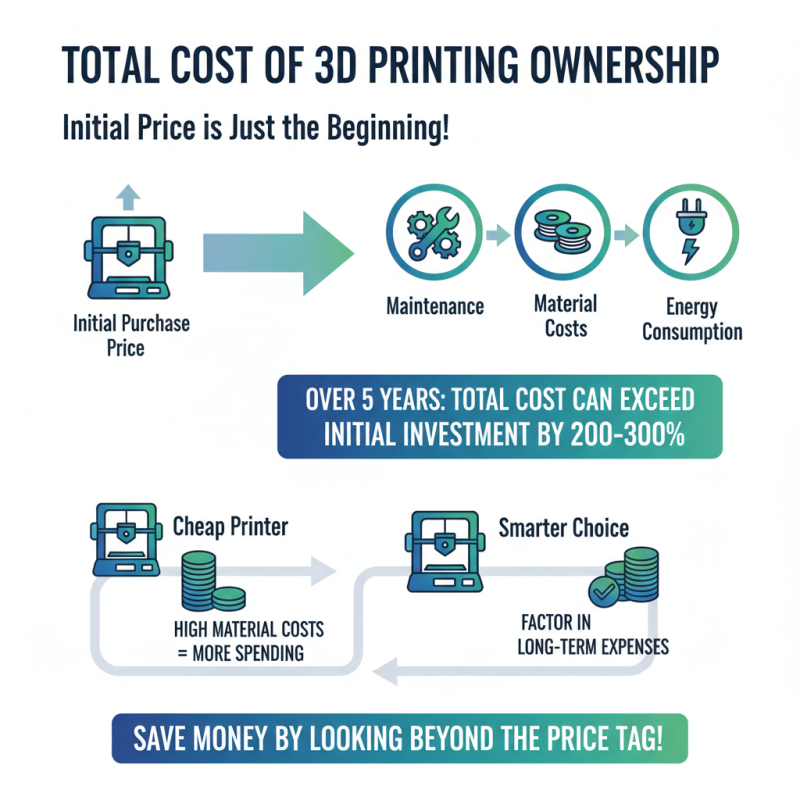

Choosing the right 3D printer involves understanding not just the initial purchase price but also the long-term costs. According to studies, the total cost of ownership can exceed the initial investment by 200% to 300% over five years. This includes maintenance, material costs, and energy consumption. It’s crucial to factor in these expenses early on. Cheap printers might save money initially, but high material costs can lead to more spending.

Tip: Always compare material prices. Some printers consume more filament or resin, affecting your budget significantly over time. Additionally, consider the reliability of the machine. Breakdowns can lead to unexpected costs and delays.

When assessing budget, reflect on your print volume. A low-cost printer may not meet your needs if you plan to produce numerous items. A reputable report indicates that printing costs vary widely; some users spend less than $1 per print, while others may exceed $25 due to inefficient setups.

Tip: Look for user reviews regarding ongoing expenses. Past users can offer insights into the hidden costs of ownership. Sometimes, a more expensive printer is cost-effective in the long run if it operates efficiently. This is a critical aspect often overlooked by first-time buyers.

Evaluating Brand Reliability and Customer Support in 3D Printer Selection

When choosing a 3D printing machine, brand reliability and customer support are critical factors. Research shows that around 68% of users prioritize support services when purchasing a printer. The complexity of 3D printing technology demands effective assistance. Having strong customer support can make or break your user experience. Many users reported being frustrated when they could not get timely help.

A study found that reliable brands significantly reduce downtime. On average, reliable brands offer 30% faster response times compared to lesser-known manufacturers. This proves advantageous, especially for businesses reliant on 3D printing. A dependable animal shape printer's user recounted how they faced operational halts due to poor support from an unknown brand. Such experiences highlight the risks of cutting corners on brand reputation.

Moreover, checking for warranties and service packages is vital. Some brands offer extensive support, covering technical issues and maintenance. Others fall short, leading to unexpected repairs. Customers should weigh these factors carefully. A solid reputation can save you from future hassles. Ignoring brand reliability may lead to regret. In the end, a little research goes a long way. Are you ready to invest wisely?

Related Posts

-

Best Professional 3D Printers for Every Business Need?

-

China Leading the World with the Best 3D Printing Machines

-

Quality Enclosed 3D Printers from China: Your Trusted Partner for Global Success

-

How to Choose the Best Professional 3D Printer for Your Business Needs

-

How to Choose the Right 3D Printer for Your Business Needs Based on Industry Trends

-

What is a High End 3D Printer and How It Transforms Your Creations