How Best Enclosed 3D Printers Will Transform the Market by 2025 with Key Insights and Strategies

The rapid evolution of technology has propelled enclosed 3D printers into the spotlight, promising to revolutionize the manufacturing landscape by 2025. As industries increasingly seek precision, reliability, and enhanced safety in additive manufacturing, the advantages of these enclosed systems become even more apparent. With their ability to maintain consistent temperature, reduce warping, and eliminate exposure to environmental contaminants, enclosed 3D printers are poised to meet the growing demands of both hobbyists and professionals alike. This article delves into key insights and strategies that highlight how these innovative machines will transform the market landscape, addressing current challenges and embracing future opportunities. By understanding the pivotal role enclosed 3D printers will play, stakeholders can better prepare for a new era of manufacturing that emphasizes efficiency and quality.

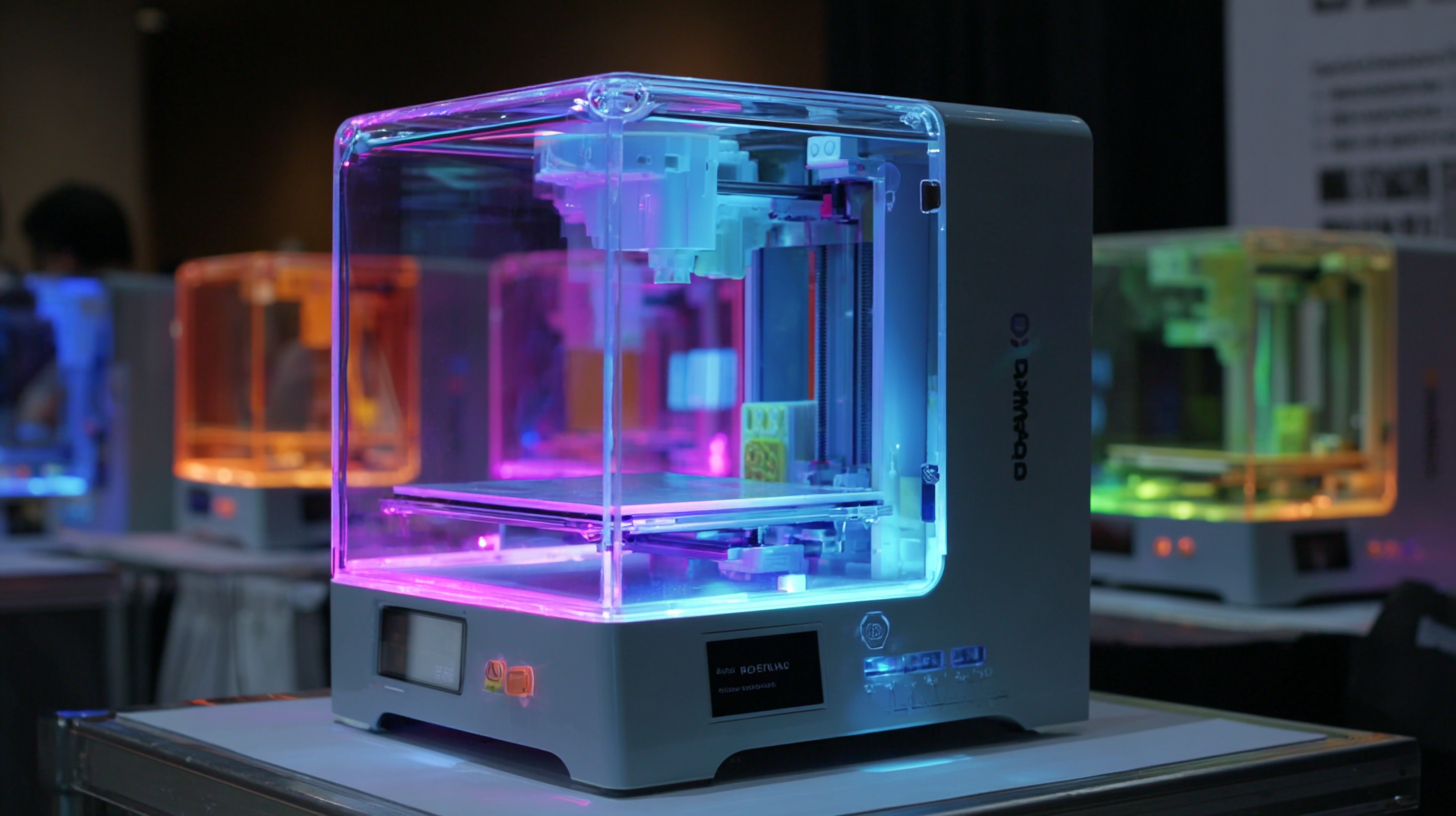

The Rise of Enclosed 3D Printers: Key Features and Advantages

The rise of enclosed 3D printers is reshaping the landscape of additive manufacturing, providing benefits that cater to both beginners and seasoned professionals. One of the standout features of these printers is their ability to maintain a stable internal environment, which is crucial for achieving high-quality prints. By minimizing temperature fluctuations and shielding the print area from drafts, enclosed printers significantly reduce the likelihood of warping and layer separation, common issues faced with open-frame models.

When considering an enclosed 3D printer, there are a few key tips to keep in mind. First, prioritize a model with good insulation and heated build plates, as these will enhance temperature control and improve print reliability. Additionally, pay attention to the size and build volume; ensuring that the printer can accommodate your project needs is essential for effective production. Lastly, look for features such as easy access for maintenance, as this can save valuable time in the long run.

As the market continues to evolve by 2025, enclosed 3D printers will play a pivotal role in advancing the technology. Their advantages extend beyond improved print quality; they also foster safer working conditions due to the reduced exposure to fumes and moving parts. This makes them particularly appealing for educational institutions and home offices, paving the way for greater adoption in various sectors.

Market Trends: How Enclosed 3D Printers Are Changing Manufacturing

The advent of enclosed 3D printers is revolutionizing the manufacturing landscape, creating significant shifts in efficiency and product quality. As these printers offer controlled environments, they mitigate issues like warping, dust contamination, and temperature fluctuations, which have long plagued traditional open-frame models. This capability not only enhances the reliability of the printing process but also expands the range of materials that can be used, allowing for more sophisticated and durable products.

Market trends show a growing adoption of enclosed 3D printers across various industries, including aerospace, automotive, and consumer goods. Companies are increasingly recognizing the value of precision and scalability that these printers provide. As they lower the barriers to innovative design and rapid prototyping, businesses using enclosed systems can speed up production cycles, reduce costs, and respond more dynamically to market demands. The transformation is not merely technological; it represents a paradigm shift in the way products are conceived, developed, and brought to market.

How Best Enclosed 3D Printers Will Transform the Market by 2025

| Category | 2023 Value (USD) | 2025 Projected Value (USD) | Growth Rate (%) | Key Insights |

|---|---|---|---|---|

| Market Size | 1.5 Billion | 3.2 Billion | 113% | Increased adoption in industrial sectors. |

| Material Demand | 200 Million | 450 Million | 125% | Growing need for high-performance materials. |

| User Base | 50,000 | 120,000 | 140% | Expanding from hobbyists to professionals. |

| Geographical Growth | North America: 40% | Asia: 45% | - | Asia-Pacific emerging as a leader in 3D printing. |

| Applications in Manufacturing | 30% | 55% | 83% | Increased use in rapid prototyping and tooling. |

Strategies for Adopting Enclosed 3D Printers in Your Business

As businesses increasingly recognize the potential of 3D printing, enclosed 3D printers are emerging as a game-changer in the additive manufacturing landscape. By offering a controlled environment that enhances material performance and provides safety benefits, these printers are set to revolutionize industries by 2025. Companies looking to integrate enclosed 3D printers into their operations must focus on strategic adoption, which begins with thorough market research. Understanding the specific needs of your business and the diverse materials available for enclosed systems is crucial in selecting the right printer.

Moreover, establishing a conducive workspace that supports the operational demands of enclosed 3D printing is essential. This includes ensuring adequate ventilation, power supply, and safe material storage. Organizations should also explore partnerships with established technology providers, as recent innovations in the field highlight strong strategic collaborations that can facilitate successful integration. Staying informed about trends and focusing on continuous training for your workforce will position your business at the forefront of the evolving 3D printing market.

Moreover, establishing a conducive workspace that supports the operational demands of enclosed 3D printing is essential. This includes ensuring adequate ventilation, power supply, and safe material storage. Organizations should also explore partnerships with established technology providers, as recent innovations in the field highlight strong strategic collaborations that can facilitate successful integration. Staying informed about trends and focusing on continuous training for your workforce will position your business at the forefront of the evolving 3D printing market.

Case Studies: Successful Implementation of Enclosed 3D Printers

The rise of enclosed 3D printers has marked a significant shift in the manufacturing landscape, particularly for industries that prioritize precision and quality. Companies like XYZPrinting have successfully integrated enclosed 3D printing into their production lines, showcasing how these machines can enhance material performance and print consistency. For instance, by using an enclosed environment, XYZPrinting minimizes the effects of fluctuating temperatures and drafts, leading to superior adhesion of layers and reduction in warping. This case study highlights not only the technical advantages but also the business impact, as firms can reduce waste and increase production efficiency.

Another notable example is the implementation of enclosed 3D printing by a leading automotive manufacturer. By utilizing these systems for prototyping and small-batch production, they were able to streamline their development processes. The controlled environment enabled the use of advanced materials that are otherwise challenging to print, such as Nylon and PETG. As a result, the company saw a decrease in lead times and costs associated with tooling. This successful transition underscores the pivotal role that enclosed 3D printers will play in transforming industries by 2025, illustrating that strategic investment in technology can lead to both operational and competitive advantages.

Future Predictions: What to Expect from Enclosed 3D Printers by 2025

As we approach 2025, the advancements in enclosed 3D printers are poised to reshape the manufacturing landscape significantly. These printers, which provide a controlled environment for the printing process, are expected to reduce the common issues associated with warping and adhesion. Users can anticipate a surge in print quality and reliability, making enclosed 3D printers a preferred choice for both hobbyists and professionals.

Tip: When investing in an enclosed 3D printer, consider models that offer dual heating zones, which can maintain optimal temperatures for different filament types. This feature can enhance print success rates and expand your material options.

Moreover, sustainability will take center stage. The rise of eco-friendly filaments and energy-efficient designs will appeal to businesses striving to reduce their carbon footprints. As regulations around manufacturing and waste tighten, adopting enclosed 3D printers can play a crucial role in maintaining compliance and promoting responsible production.

Tip: Look for printers with advanced filtration systems to minimize VOC emissions. This not only helps ensure a safer working environment but also aligns your practices with green manufacturing standards.

Projected Growth of Enclosed 3D Printers by 2025

This chart illustrates the projected market share growth of enclosed 3D printers over the next few years, highlighting the expected increase in adoption and its significant impact on the overall 3D printing market by 2025.