7 Digital Innovations Transforming the Professional 3D Printer Industry

As the demand for customized solutions and rapid prototyping continues to soar across various industries, the professional 3D printer market is experiencing a significant transformation driven by digital innovations. According to a recent industry report by Grand View Research, the global 3D printing market is projected to reach USD 62.79 billion by 2028, with professional 3D printers playing a pivotal role in this growth.

Key advancements in materials, cloud computing, and AI-driven design tools are enabling businesses to enhance their production capabilities while reducing lead times and costs. This blog will explore seven groundbreaking digital innovations that are not only reshaping the capabilities of professional 3D printers but are also setting new standards in manufacturing efficiency and product customization.

As we delve into these transformative technologies, it becomes evident that the future of professional 3D printing is ripe with possibilities, poised to revolutionize how industries approach design and production.

Impact of Artificial Intelligence on 3D Printing Efficiency

Artificial intelligence (AI) is revolutionizing the 3D printing industry, particularly in enhancing efficiency and productivity across various sectors. By employing machine learning algorithms and generative design, companies in the aerospace sector are able to optimize their printing processes, reducing time and material waste. AI can predict failures in real-time, allowing for adjustments that prevent costly downtime. This integration not only streamlines production but also elevates the quality of printed parts, meeting the rigorous standards demanded by aerospace applications.

Furthermore, the impact of AI extends to materials innovation, where algorithms assist in developing new composites and alloys tailored for specific applications. As aerospace companies continue to push the boundaries of design, AI-driven processes enable the creation of lighter, stronger, and more efficient components. This shift not only assures better performance but also enhances sustainability within the industry by minimizing the environmental footprint of manufacturing. Overall, the fusion of AI and 3D printing is paving the way for unprecedented advancements, signifying a transformative era for the aerospace market.

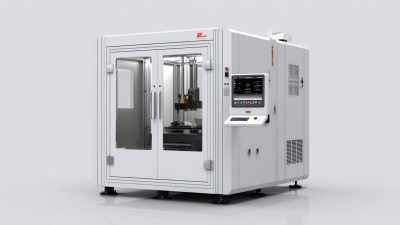

Advancements in Material Science Enhancing 3D Printing Capabilities

The evolution of material science is significantly reshaping the 3D printing landscape, leading to remarkable improvements in the capabilities of professional-grade printers. New composite materials, such as carbon fiber-infused filaments and high-temperature thermoplastics, are allowing manufacturers to produce stronger, lighter, and more durable components than ever before. These advancements not only enhance the structural integrity of printed parts but also open doors to innovative applications across various industries, from aerospace to healthcare.

Moreover, bio-based and eco-friendly materials are becoming more prevalent, driven by a growing demand for sustainable practices. Materials like biodegradable thermoplastics are not only reducing the environmental impact of 3D printing but also maintaining high-performance standards. This transition towards sustainable materials aligns with global efforts to minimize waste and promote renewable resources, showcasing how material science innovations can go hand in hand with ecological responsibility. As these exciting developments continue to emerge, the professional 3D printer industry is poised for unprecedented growth and transformation.

Innovations in 3D Printing Materials

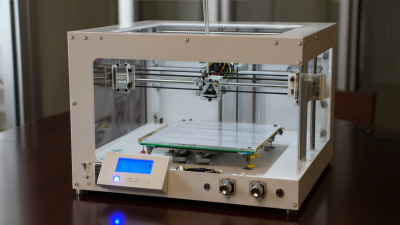

The Role of IoT in Real-Time Monitoring of 3D Printing Processes

The incorporation of the Internet of Things (IoT) in the 3D printing industry is revolutionizing how professionals monitor and manage their printing processes. By enabling real-time monitoring, IoT technology allows for instantaneous data collection from printers, which improves accuracy and reduces errors. According to a report by MarketsandMarkets, the IoT in manufacturing is projected to grow from $28.3 billion in 2020 to $87 billion by 2025, highlighting the increasing reliance on connected devices to enhance productivity and efficiency.

With IoT sensors integrated into 3D printers, manufacturers can track variables such as temperature, humidity, and material flow in real time. This capability not only ensures optimal printing conditions but also provides predictive maintenance insights. Research from Gartner indicates that over 70% of organizations employing IoT solutions report improved operational efficiency, emphasizing how real-time data not only enhances the quality of 3D printed products but also significantly cuts down on waste and downtime. As the professional 3D printer industry continues to evolve, the integration of IoT will be pivotal in driving innovation and ensuring high-quality production standards.

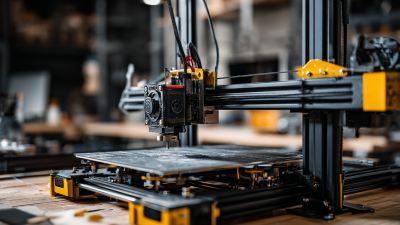

Automation and Robotics Revolutionizing the 3D Printing Workflow

The integration of automation and robotics into the 3D printing workflow marks a significant shift in the professional 3D printer industry. With advancements in technology, printers can now operate with minimal human intervention, streamlining production processes. Automated systems allow for rapid material preparation, printing, and post-processing, significantly reducing cycle times and enhancing productivity. This efficiency not only lowers operational costs but also enables manufacturers to meet increasing demand without compromising on quality.

Moreover, robotics play a crucial role in the handling and maintenance of 3D printers. Automated robotic arms can manage multiple printers simultaneously, perform maintenance checks, and replace materials as needed. This reduces the risk of errors associated with manual handling and allows skilled workers to focus on more complex tasks, such as design and problem-solving. As robotics continue to evolve, we can expect even greater solutions to be integrated into the 3D printing workflow, paving the way for a smarter and more efficient industry.

Sustainability Innovations Driving Eco-Friendly 3D Printing Practices

Sustainability has become a cornerstone in the evolution of the 3D printing industry, driving significant innovations designed to minimize environmental impact. One of the most promising developments is the use of bio-based and recycled materials. These materials not only reduce reliance on virgin plastics but also utilize waste products, transforming what would be discarded into valuable resources for 3D printing. As manufacturers increasingly adopt these sustainable filaments, the carbon footprint of production can be significantly lowered, promoting a circular economy.

Moreover, advancements in energy-efficient printing technologies are paving the way for greener production processes. Manufacturers are now investing in printers that consume less energy and utilize smart technologies to optimize power usage. Techniques such as energy recovery and on-demand printing reduce waste and energy consumption, making the overall printing process more eco-friendly. By integrating these innovations, the 3D printing industry not only addresses environmental concerns but also appeals to a growing consumer base that prioritizes sustainability, establishing itself as a leader in responsible manufacturing practices.

Related Posts

-

Ultimate Guide to Finding the Best Professional 3D Printer for Your Business Needs

-

Envisioning the Future of 3D Printing: Why the Best Desktop Models Will Lead Innovation

-

Understanding the Benefits of the Best Large 3D Printer for Global Buyers

-

China Leading the World with the Best 3D Printing Machines

-

Addressing Common Issues with Enclosed 3D Printers: A Comprehensive Guide

-

Exploring the Top Industrial 3D Printers for Global Buyers in 2023