Addressing Common Issues with Enclosed 3D Printers: A Comprehensive Guide

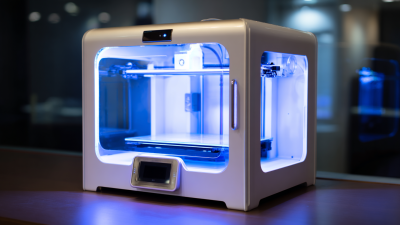

The rise of enclosed 3D printers has transformed the landscape of additive manufacturing, offering greater control over print environments and enhancing the quality of finished products.

According to a report by Markets and Markets, the global 3D printing market is expected to reach $34.8 billion by 2026, driven in part by the increasing adoption of enclosed 3D printers across various industries like aerospace, automotive, and healthcare.

These printers not only provide a safer working environment by limiting exposure to harmful particles and fumes but also improve print consistency by maintaining a stable temperature and humidity level.

However, despite their advantages, users often encounter common issues that can hinder their 3D printing experience. This comprehensive guide aims to address those challenges, providing insights and solutions to optimize the use of enclosed 3D printers and ensure successful printing outcomes.

Key Features to Evaluate in Enclosed 3D Printers

When selecting an enclosed 3D printer, it's essential to evaluate key features that can significantly enhance your printing experience and output quality. One critical aspect is temperature control; studies indicate that maintaining a stable environment can improve print adhesion and reduce warping, especially for materials like ABS and PETG. According to a report by IDC, 65% of users experienced improved print success rates in controlled environments compared to open setups, highlighting the importance of an enclosed chamber.

Another important feature to consider is the filtration system. With the growing concerns about VOC emissions from various filaments, an effective air filtration system can ensure a safe working environment. A recent analysis by the American Society for Testing and Materials (ASTM) found that enclosed printers equipped with HEPA filters reduced airborne particles by up to 99%, making them not only a practical choice but also a healthier one for users. Additionally, it’s crucial to evaluate the build volume and ease of access to the print area, which can greatly impact user-friendliness and project scalability. These elements combined help form a comprehensive view of what makes an enclosed 3D printer suitable for both hobbyists and professionals alike.

Addressing Common Issues with Enclosed 3D Printers: A Comprehensive Guide - Key Features to Evaluate in Enclosed 3D Printers

| Feature | Description | Importance | Common Issues Addressed |

|---|---|---|---|

| Enclosed Build Chamber | A fully enclosed environment that stabilizes temperature and reduces drafts. | High | Warping and temperature fluctuations. |

| HEPA Filtration System | Filters out harmful fumes and particles produced during printing. | Medium | Air quality issues, odors. |

| User-Friendly Interface | Intuitive controls for easy setup and printing. | High | User frustration and operational mistakes. |

| Stable Platform | A robust print bed that minimizes vibrations during operation. | High | Misalignments and failed prints. |

| Temperature Control | Maintains an optimal printing temperature for various materials. | High | Material-specific issues like stringing and adhesion. |

Common Performance Issues in Enclosed 3D Printers Compared

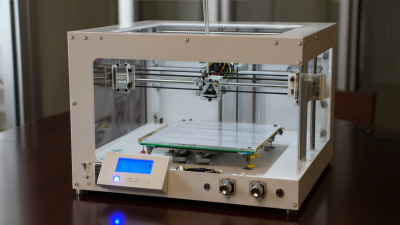

Enclosed 3D printers offer a wealth of advantages, especially when it comes to maintaining stable print conditions. However, they can also encounter a variety of performance issues that can affect print quality and consistency. One common issue is temperature regulation; even minor fluctuations can lead to warping and layer adhesion problems. It's essential for users to invest in reliable temperature control systems and, if possible, to incorporate features such as heated chambers to maintain optimal thermal environments.

Another challenge faced by enclosed 3D printers is limited airflow, which can contribute to the accumulation of volatile fumes during the printing process. Regular maintenance, including cleaning and making sure ventilation systems are functioning properly, can help mitigate this issue. Users should also consider integrating air purification solutions to enhance air quality and safety in the workspace. Addressing these common issues not only improves the performance of enclosed 3D printers but also elevates the overall user experience, making it more efficient for professionals and hobbyists alike.

Common Performance Issues in Enclosed 3D Printers

Materials Compatibility and Its Impact on Print Quality

When it comes to enclosed 3D printers, materials compatibility plays a pivotal role in achieving high print quality. While these printers provide a controlled environment that reduces the risks of warping and contraction, not all materials respond equally to the secured temperatures and humidity levels. For instance, widely used filaments like PLA can work well in enclosed spaces, but more advanced materials such as ABS and PETG may require specific conditions for optimal adhesion and layer bonding. Understanding the thermal properties and specific requirements of each material is crucial for selecting the right filament for your project.

Moreover, the choice of materials directly influences the surface finish and mechanical properties of the final print. Enclosed environments promote uniform heat distribution, but materials that are not suited for higher temperatures can lead to inconsistency in printing results. For example, selecting a material with a lower glass transition temperature in an enclosed printer might result in a print that degrades in quality or fails entirely due to excessive heat exposure. Therefore, it's essential to conduct thorough research on filaments and how they behave in an enclosed setup to enhance print quality and achieve desired outcomes efficiently.

Cost Analysis: Budget vs. High-End Enclosed 3D Printers

When considering the purchase of an enclosed 3D printer, one of the primary factors that influences decision-making is the cost. The market offers a diverse range of options, from budget-friendly models at lower price points to high-end printers that come with advanced features and enhanced performance.

Budget printers are often attractive to beginners or hobbyists, as they provide a relatively low initial investment while covering basic printing needs. However, these economical options may lack essential features such as superior build quality, consistent temperature control, and advanced software capabilities, which can affect print quality and reliability over time.

Budget printers are often attractive to beginners or hobbyists, as they provide a relatively low initial investment while covering basic printing needs. However, these economical options may lack essential features such as superior build quality, consistent temperature control, and advanced software capabilities, which can affect print quality and reliability over time.

On the other hand, high-end enclosed 3D printers justify their price tags by integrating top-notch components and technologies that significantly enhance the user experience. These printers typically offer features like dual extrusion, automatic bed leveling, and advanced filtration systems, ensuring not only higher quality prints but also a safer working environment. For businesses or serious enthusiasts looking to produce high-quality, intricate models, investing in a high-end machine may lead to long-term savings by minimizing failed prints and the need for frequent maintenance. Understanding these cost dynamics is crucial for anyone looking to make an informed choice in the 3D printing landscape.

User-Friendly Design Elements: Which Models Stand Out?

When exploring user-friendly design elements in enclosed 3D printers, several models stand out due to their intuitive interfaces and practical features. Key aspects such as easy assembly, minimal maintenance requirements, and connectivity options significantly enhance the user experience. For instance, many modern printers now incorporate touchscreen controls that simplify navigation and allow users to pre-set print jobs conveniently.

**Tips:** When selecting an enclosed 3D printer, consider models that offer clear and accessible user manuals to aid in setup and operation. Look for printers with a robust community or customer support, which can provide additional resources like tutorials and troubleshooting assistance.

Moreover, the design of the printer should facilitate a clean and safe workflow. Features such as filament sensors, automatic bed leveling, and quiet operation can dramatically improve the overall experience. Choosing a printer with these built-in functionalities not only saves time but also diminishes the learning curve for beginners.

**Tips:** Invest in a model that includes good safety mechanisms, such as door locks and temperature controls, to ensure a safe printing environment, especially in homes with children or pets. Consider reading reviews and watching demonstration videos to gain insights into the printer's ease of use and functionality before making a purchase.

Related Posts

-

Market Forecast for High End 3D Printers in 2025 and How to Choose the Right One for Your Business

-

7 Essential Tips for Choosing the Best High Temperature 3D Printer

-

Unlocking the Future: Top 5 Digital Innovations in High-End 3D Printing

-

Ultimate Guide to Choosing the Best Enclosed 3D Printer for Your Business Needs

-

China Leading the World with the Best 3D Printing Machines

-

Ultimate Checklist for Choosing the Best Enclosed 3D Printer for Your Business Needs