How to Choose the Best Professional 3D Printer for Your Business Needs

In recent years, the demand for professional 3D printers has surged, driven by advancements in technology and a growing recognition of additive manufacturing's potential across various industries. According to a report by MarketsandMarkets, the global 3D printing market is projected to reach $34.8 billion by 2024, growing at a compound annual growth rate (CAGR) of 25.76% from 2019 to 2024. This remarkable growth highlights the increasing adoption of professional 3D printers in sectors such as aerospace, automotive, healthcare, and consumer goods, where rapid prototyping and custom solutions are invaluable.

As businesses seek to enhance their production capabilities and innovate faster, choosing the right professional 3D printer becomes critical to meeting unique operational needs and staying competitive in the evolving marketplace. This guide will explore essential factors and considerations for selecting the best professional 3D printer tailored to your business objectives.

Understanding Different Types of 3D Printers for Professional Use

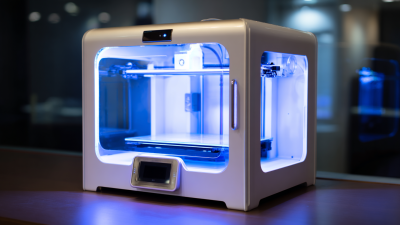

When selecting a professional 3D printer for your business needs, understanding the various types of printers available is crucial. The primary categories include In-office and In-lab printers, each tailored to different operational contexts. In-office 3D printers are ideal for rapid prototyping and creating functional parts on-site, allowing for quick iterations and immediate access to models. On the other hand, In-lab printers are better suited for specialized tasks, such as producing dental models or complex geometries that require a more controlled environment.

In terms of technology, several versatile options are available. Stereolithography (SLA) is known for its high precision and smooth surface finish, making it a popular choice for industries where detail matters, such as jewelry design and dental applications. Selective Laser Sintering (SLS), meanwhile, excels in creating durable parts from a range of materials, ideal for functional prototypes or production-level components. Each printer type and technology presents distinct advantages, so businesses must carefully evaluate their specific requirements and workflows to choose the best-fit 3D printer for their operations.

Key Features to Consider When Selecting a Professional 3D Printer

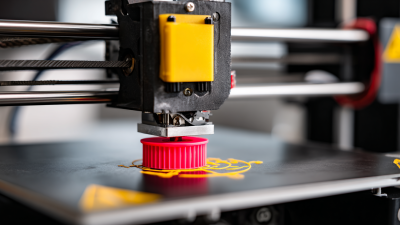

When selecting a professional 3D printer for your business, understanding the key features is crucial to ensure you make an informed decision. First, consider the printing technology that best fits your needs. Options like Fused Deposition Modeling (FDM), Stereolithography (SLA), or Selective Laser Sintering (SLS) each have unique advantages. For instance, FDM is cost-effective and ideal for prototyping, while SLA offers finer detail, making it suitable for intricate designs. Aligning the technology with your application is essential to maximizing efficiency and output quality.

Another critical feature is the build volume, which determines the size of the objects you can create. A larger build volume may be necessary for businesses focused on large-scale production or intricate assemblies. Additionally, look for printers with advanced material compatibility. Some businesses may require the use of specialized materials, such as flexible filaments or high-temperature polymers, which not all printers can accommodate. Lastly, consider the ease of use and support services provided by the manufacturer, as good customer service can alleviate challenges during setup and maintenance, ensuring you get the most out of your investment.

Evaluating Printing Technology: FDM, SLA, SLS, and More

When selecting a professional 3D printer for your business, understanding the various printing technologies is crucial.

Fused Deposition Modeling (FDM) is one of the most popular options due to its cost-effectiveness and ease of use. It works by extruding melted thermoplastic filament layer by layer, making it ideal for creating functional prototypes and end-use parts. However, FDM may not provide the level of detail required for intricate designs.

Stereolithography (SLA) offers a different approach by utilizing a UV laser to cure resin into solid objects. This method is known for its high precision and smooth surface finish, making it suitable for applications that require intricate detail, such as jewelry modeling or dental applications. However, the materials can be more expensive, and post-processing is often necessary.

Selective Laser Sintering (SLS) employs a laser to fuse powdered materials, resulting in durable parts with excellent mechanical properties. This method can handle complex geometries and does not require support structures, which is a major advantage. For businesses focused on functional prototypes or production parts that demand strength, SLS might be the preferred choice.

Tip: Consider the specific requirements of your projects—such as material properties, detail level, and production volume—when choosing a technology. Also, assess the total cost of ownership, including material expenses and maintenance, to ensure a well-rounded decision.

Assessing Material Compatibility for Business-Specific Applications

When selecting a professional 3D printer for your business, one of the most critical aspects to consider is material compatibility. Different 3D printing technologies utilize various materials, and each material has distinct properties that can significantly impact the final product's quality, durability, and usability. For instance, if your business requires printing prototypes or end-use parts that must withstand high temperatures or mechanical stress, it’s essential to choose a printer that supports industrial-grade materials such as ABS, Nylon, or composites. Evaluating your specific application requirements will guide you in selecting a printer that can deliver the necessary performance.

In addition to mechanical properties, businesses must also assess the aesthetic qualities of the materials available. If your projects demand intricate designs with smooth finishes or vibrant colors, printers compatible with materials like PLA or resin might be more appropriate. Furthermore, it’s crucial to consider the availability and cost of these materials, as they can significantly impact your operating budget. Researching the accompanying ecosystem of materials for your chosen printer can ensure that you remain flexible and responsive to evolving business needs while also maximizing the return on your investment.

How to Choose the Best Professional 3D Printer for Your Business Needs - Assessing Material Compatibility for Business-Specific Applications

| Material Type | Compatibility | Best Applications | Cost per kg | Strength Rating (MPa) |

|---|---|---|---|---|

| PLA | High | Prototyping, Educational Models | $25 | 50 |

| ABS | Medium | Mechanical Parts, Automotive | $30 | 40 |

| PETG | High | Food Containers, Medical Devices | $35 | 50 |

| Nylon | Medium | Textiles, Functional Prototypes | $40 | 45 |

| Resin | High | Jewelry, Miniatures | $100 | 70 |

Cost vs. Performance: Finding the Right Balance for Your Needs

When selecting a professional 3D printer for your business, it's crucial to strike the right balance between cost and performance. Today's market offers a diverse range of options, making it essential to assess your specific needs carefully. Consider the cost of ownership, including maintenance and material expenses, against the performance capabilities that will meet your production demands. A high-performance printer may come with a higher initial investment, but if it significantly boosts efficiency or unlocks new capabilities, it can provide greater long-term value.

In a rapidly evolving business landscape, companies must also consider how these choices align with broader strategic goals. Just as organizations face pressure to innovate while managing costs in the financial services sector, your choice in 3D printing technology should facilitate growth without sacrificing efficiency. Adopting a solution that balances these aspects can be transformative, enabling you to explore new markets and enhance product offerings while keeping operational costs in check. The right 3D printer not only fulfills immediate production needs but also supports sustainable business growth, ensuring that you stay competitive in a dynamic environment.

Related Posts

-

7 Essential Tips for Choosing the Best High Temperature 3D Printer

-

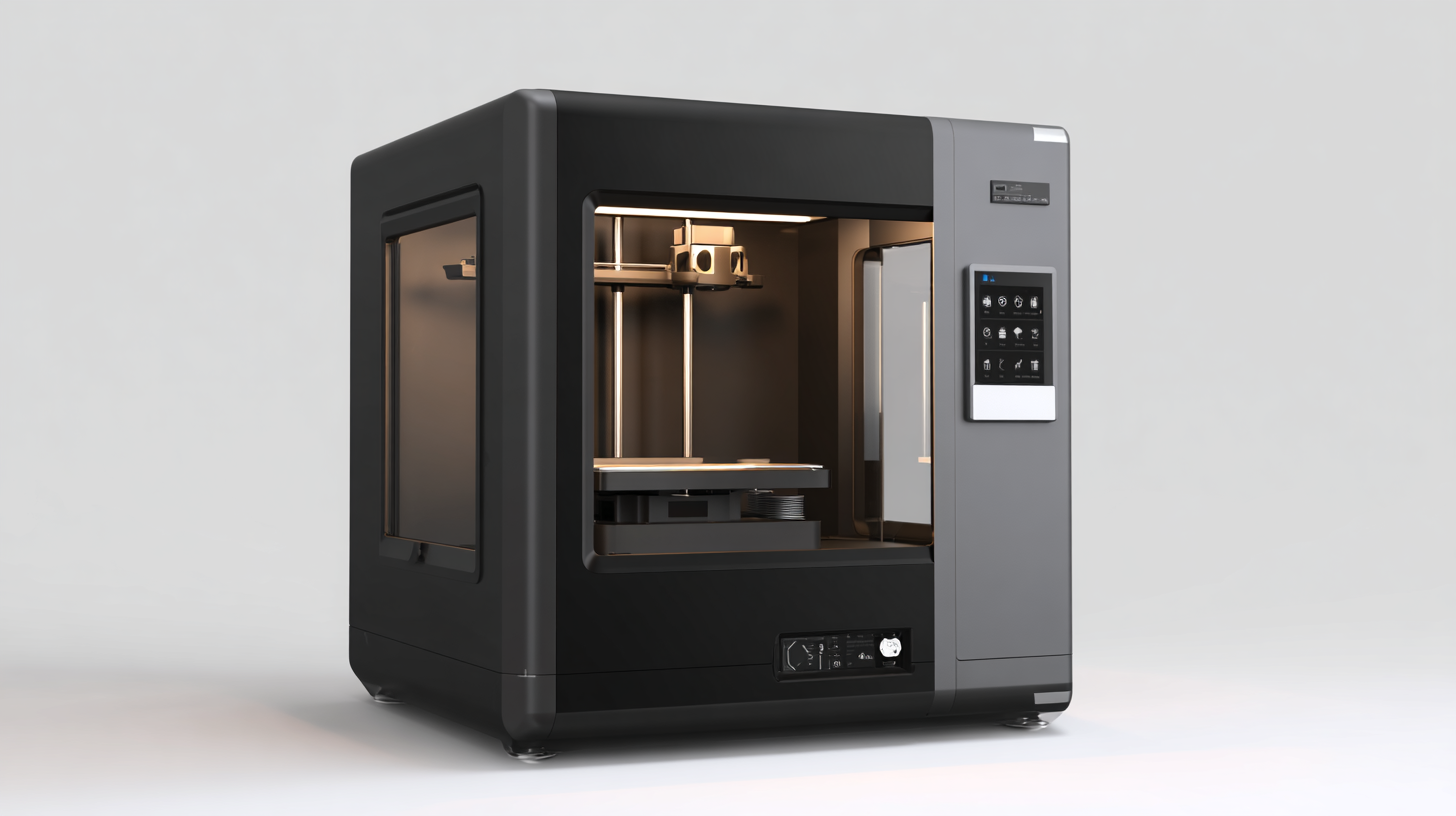

Ultimate Guide to Choosing the Best Enclosed 3D Printer for Your Business Needs

-

Ultimate Checklist for Choosing the Best Enclosed 3D Printer for Your Business Needs

-

Navigating Export Certifications for the Best Home 3D Printer and What You Need to Know

-

Market Forecast for High End 3D Printers in 2025 and How to Choose the Right One for Your Business

-

Unlocking the Future: Top 5 Digital Innovations in High-End 3D Printing