Mastering the Art of Choosing the Best High Temperature 3D Printer for Your Needs

In recent years, the demand for high temperature 3D printers has surged, driven by advancements in materials technology and a growing need for robust manufacturing solutions across various industries such as aerospace, automotive, and medical. According to a report by MarketsandMarkets, the 3D printing market is projected to reach $34.8 billion by 2024, with high temperature 3D printers playing a crucial role in this expansion. These printers are designed to process high-performance thermoplastics, including PEEK and Ultem, which can withstand extreme environmental conditions. However, with the plethora of options available, choosing the right high temperature 3D printer tailored to specific needs can be challenging. This blog will provide essential insights and top strategies for finding quality suppliers, ensuring that you make an informed decision that aligns with your production requirements and technical specifications.

Understanding the Importance of High Temperature 3D Printing in Specialized Industries

High temperature 3D printing plays a crucial role in specialized industries where material performance and durability are paramount. Industries such as aerospace, automotive, and medical require components that can withstand extreme conditions, including high heat and pressure. Traditional materials often fall short of these demands, making high-temperature filament options like PEEK, ULTEM, and Nylon available for 3D printing essential for creating reliable prototypes and end-use parts.

High temperature 3D printing plays a crucial role in specialized industries where material performance and durability are paramount. Industries such as aerospace, automotive, and medical require components that can withstand extreme conditions, including high heat and pressure. Traditional materials often fall short of these demands, making high-temperature filament options like PEEK, ULTEM, and Nylon available for 3D printing essential for creating reliable prototypes and end-use parts.

The complexity of environments in which these parts operate makes high temperature 3D printing an invaluable asset. For instance, aerospace components must endure severe thermal stresses, necessitating materials that can not only bear high temperatures but also exhibit robust mechanical properties. Furthermore, in the medical field, specialized devices and tools made with high-temperature 3D printing ensure compliance with safety standards while maintaining integrity under sterilization processes. Understanding the significance of these capabilities is vital for industries aiming to innovate and achieve competitive advantages through advanced manufacturing techniques.

Key Considerations for Selecting a High Temperature 3D Printer

When selecting a high temperature 3D printer, several key considerations play a crucial role in meeting your specific needs. Firstly, the maximum extrusion temperature is vital. Printers that can reach temperatures above 300°C are capable of processing high-performance materials like PEEK and Ultem, which are essential for industries such as aerospace and automotive where high thermal and mechanical stability is required. According to a 2022 report from SmarTech Analysis, the demand for high-temperature 3D printing in industrial applications is projected to grow at a compound annual growth rate (CAGR) of 25%, underscoring the need for precision in selecting the right printer.

Another essential consideration is the build volume, which can significantly impact the types of projects you can undertake. A larger build volume provides the flexibility to create more complex parts or several components simultaneously, making it particularly advantageous for prototyping and small batch production. Data from Wohlers Associates indicates that the market for larger-format 3D printers is increasing, with many manufacturers incorporating scalable features into their designs. Therefore, assessing the specific requirements of your projects, including material compatibility and print size, will ensure that you invest in a high temperature 3D printer that aligns with your operational goals.

Top Brands and Models for High Temperature 3D Printers in the Market

When it comes to high-temperature 3D printers, several brands and models stand out in the market, meeting the increasing demands for advanced materials and precision. According to a recent industry report by Wohlers Associates, the market for 3D printing is projected to grow from $12 billion in 2020 to over $35 billion by 2025, with high-temperature 3D printing technologies playing a significant role in this expansion. Brands like Stratasys and Markforged have been at the forefront, offering machines that can print with materials like PEEK and Ultem, which require high processing temperatures and robust performance.

Among the top models, Stratasys' F900 and Markforged's Metal X are noteworthy for their ability to handle high-temperature applications in industries like aerospace and automotive. The F900, equipped with a build chamber that can reach up to 300°C, allows for the printing of complex geometries using engineering-grade thermoplastics. Similarly, the Metal X utilizes a unique process for metal printing, ensuring high precision and strength in finished parts, crucial for critical applications. As the demand for high-performance materials grows, selecting the right printer will depend on specific applications, material compatibility, and the technological capabilities each brand offers.

Regulatory Compliance: Navigating Certification for High Temperature 3D Printing

When diving into the world of high-temperature 3D printing, regulatory compliance is a critical aspect that can often be overlooked. Navigating the certification process can be daunting yet essential for ensuring that your printing practices adhere to industry standards. Each region may have specific requirements, so it’s important to familiarize yourself with local regulations regarding material safety and environmental impact. This not only protects your business but also assures clients of the integrity of your products.

**Tip:** Start by researching the necessary certifications for the materials you intend to use. Many high-temperature polymers require specific compliance certifications like RoHS or REACH.

Another key point is to keep documentation organized. Maintaining well-documented compliance records can facilitate smoother audits and assessments. It’s advisable to collaborate with suppliers who can provide material certifications and ensure that your 3D printing equipment meets relevant safety standards.

**Tip:** Implement a compliance checklist to streamline your processes; this can include verification of supplier certifications and regular audits of your printing setups.

Temperature Resistance of Various 3D Printing Materials

Future Trends in High Temperature 3D Printing Technology and Their Impact on Industry

As high temperature 3D printing continues to evolve, several key trends are shaping the future of this technology and its applications across various industries. One significant trend is the increasing use of advanced polymers and composites that can withstand elevated temperatures. This allows for the production of parts that are not only durable but also lightweight, making them ideal for aerospace and automotive applications. Manufacturers are investing in research and development to refine these materials, ensuring they offer improved mechanical properties and resistance to thermal degradation.

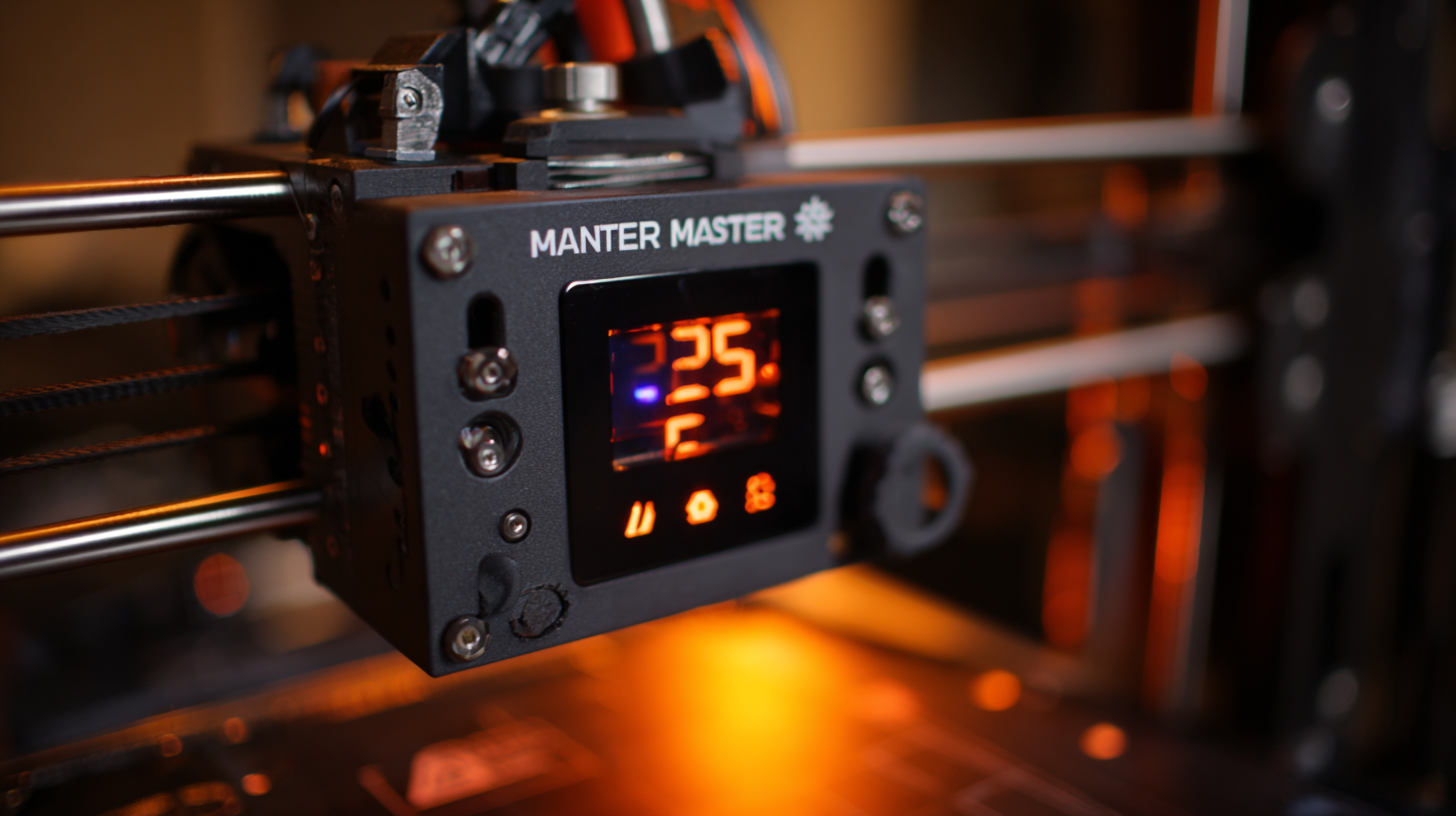

Another noteworthy development is the integration of smart technology into high temperature 3D printers. Innovations such as real-time monitoring systems and artificial intelligence are enhancing printing accuracy and efficiency. By collecting data throughout the printing process, these systems enable operators to detect potential issues early, minimizing waste and reducing production time. Additionally, the collaboration between different industries in developing customized solutions is paving the way for tailored applications, further driving the adoption of high temperature 3D printing in sectors ranging from energy to healthcare, where precision and reliability are paramount.