Ultimate Guide to Choosing the Best Enclosed 3D Printer for Your Business Needs

In the rapidly evolving landscape of additive manufacturing, the role of an enclosed 3D printer has become increasingly pivotal for businesses seeking precision and reliability. According to a report by MarketsandMarkets, the global 3D printing market is expected to grow from $13.7 billion in 2020 to $34.8 billion by 2026, indicating a significant uptick in demand across various sectors.

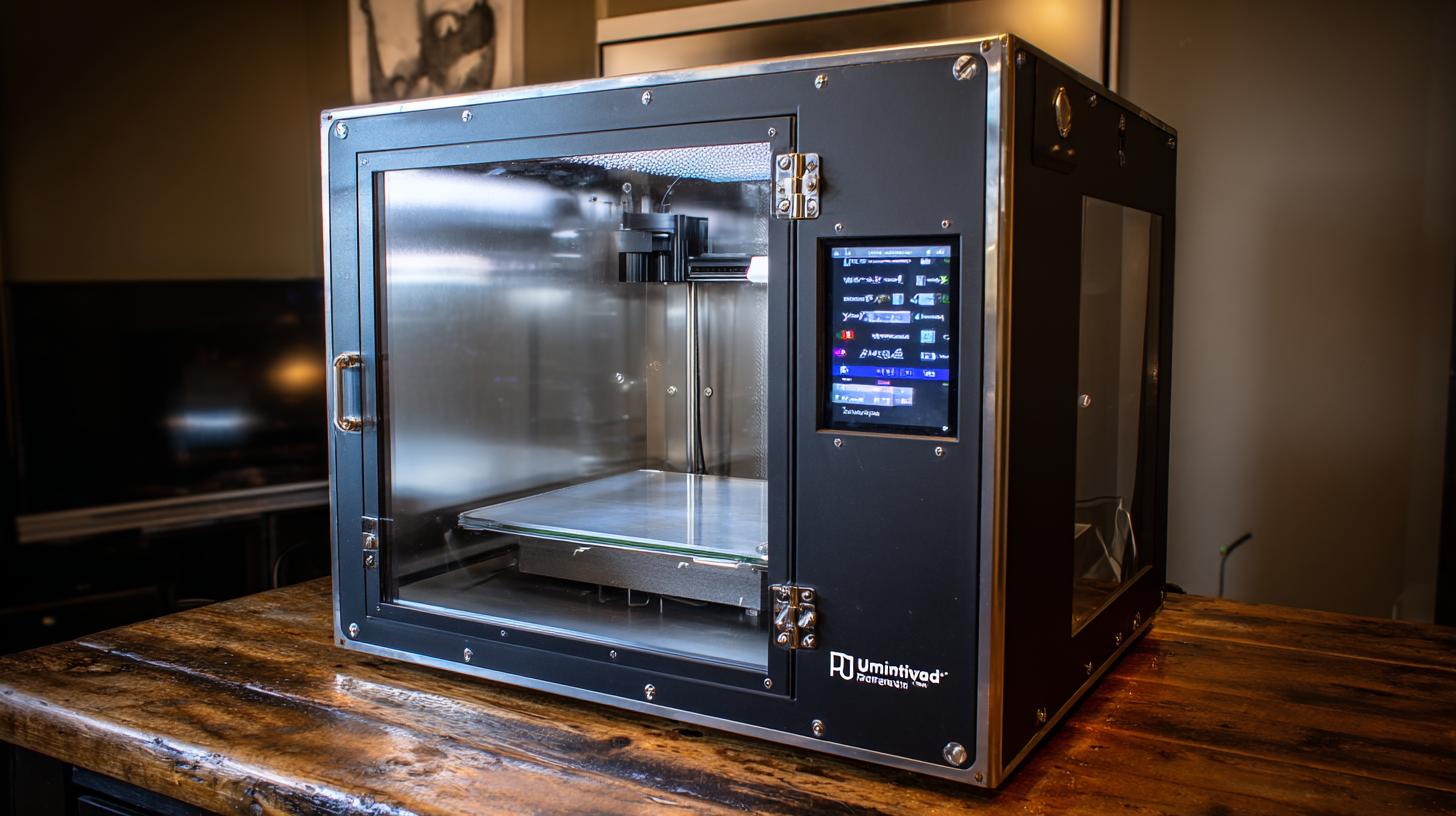

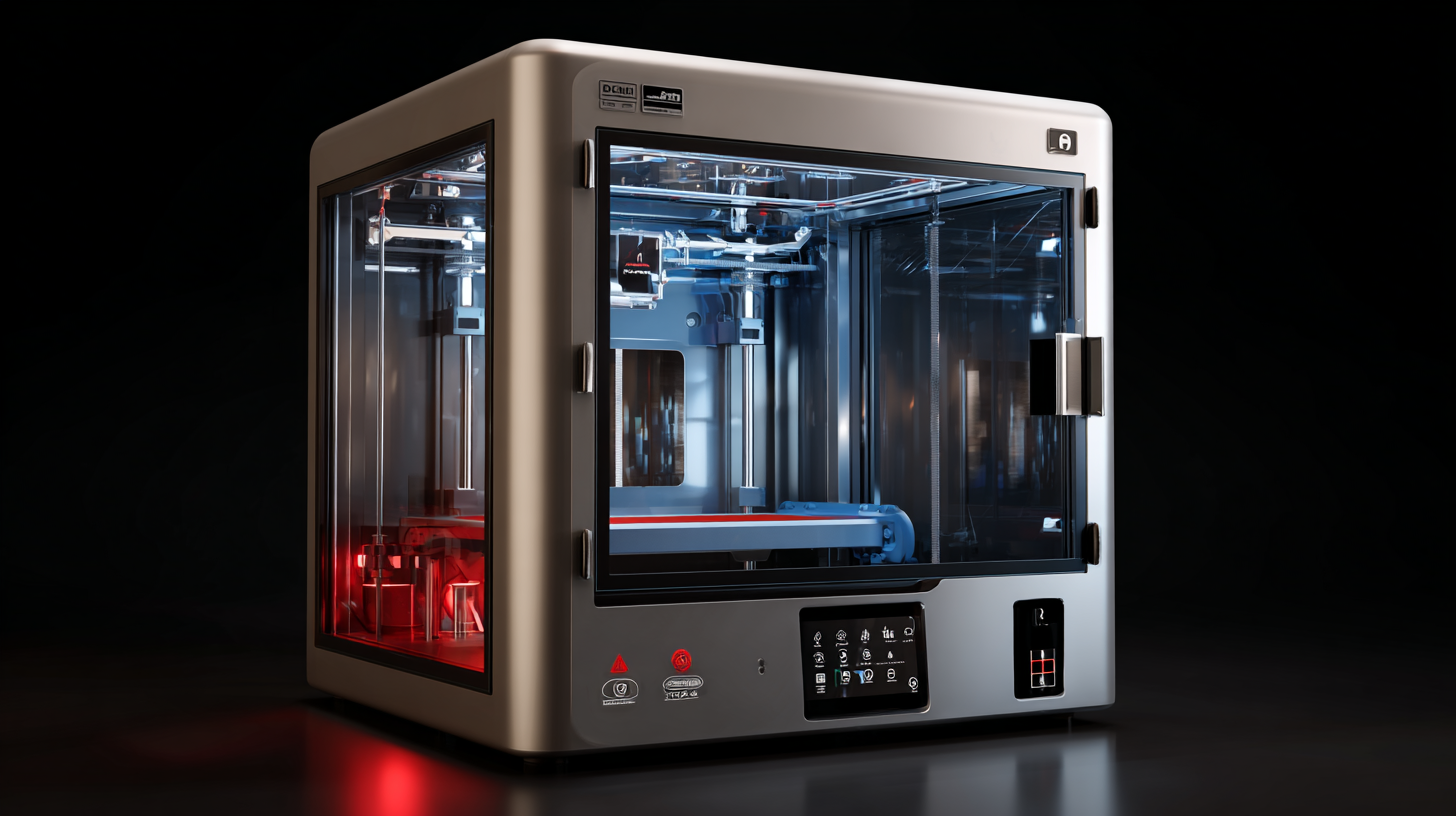

One of the key advantages of an enclosed 3D printer is its ability to maintain a controlled environment, which is essential for processing high-performance materials like ABS and Nylon. This environment minimizes warping and ensures superior print quality, making it a vital investment for companies aiming to enhance their manufacturing processes. As the market expands, understanding the nuances of selecting the right enclosed 3D printer becomes imperative for businesses looking to stay competitive and innovate efficiently.

One of the key advantages of an enclosed 3D printer is its ability to maintain a controlled environment, which is essential for processing high-performance materials like ABS and Nylon. This environment minimizes warping and ensures superior print quality, making it a vital investment for companies aiming to enhance their manufacturing processes. As the market expands, understanding the nuances of selecting the right enclosed 3D printer becomes imperative for businesses looking to stay competitive and innovate efficiently.

Key Features to Consider When Selecting an Enclosed 3D Printer for Your Business

When selecting an enclosed 3D printer for your business, several key features should be at the forefront of your decision-making process. First and foremost, print volume is critical, as it directly influences the size of the objects you can produce. According to a report by SmarTech Analysis, the demand for large-format 3D printing has been increasing, with projections estimating a market growth of 25% CAGR through 2026. This surge highlights the necessity for businesses needing to create larger prototypes or parts to invest in models that offer substantial build volumes.

Another essential factor to consider is the printer's material compatibility. A study published by Wohlers Associates indicates that over 60% of professional 3D printer users prioritize material variety to meet diverse application needs. Your choice of an enclosed 3D printer should thus accommodate a wide range of materials, including high-performance thermoplastics and composites, to ensure versatility in production workflows. Furthermore, effective temperature control within enclosed systems is crucial for printing with materials prone to warping or delamination, ensuring you achieve the best possible print quality.

Understanding Different 3D Printing Technologies and Their Applications

When choosing an enclosed 3D printer for your business, it's crucial to understand the various 3D printing technologies available today. Fused Deposition Modeling (FDM) is one of the most common methods, ideal for producing durable prototypes and functional parts. It works by extruding melted thermoplastic filament layer by layer, allowing for intricate designs and a range of material choices. For businesses focusing on medical or engineering applications, Stereolithography (SLA) offers unmatched precision and a smooth surface finish by utilizing a UV laser to cure liquid resin.

**Tip:** Always assess your specific application needs against the capabilities of each technology. FDM printers, for example, are generally more affordable but may not yield the fine details required for precision components, where SLA shines.

Additionally, Selective Laser Sintering (SLS) is a powerful option for producing complex geometries without the need for support structures, using a laser to fuse powdered materials. This technology is particularly beneficial for small production runs and custom parts.

**Tip:** Consider the material options available for each printing technology; SLS typically supports a wider variety of polymers and can result in strong, functional parts suitable for operational use in competitive industries.

Comparison of 3D Printing Technologies

Cost Analysis: Budgeting for Your Enclosed 3D Printer Investment

Investing in an enclosed 3D printer for your business can significantly enhance your production capabilities, but understanding the costs involved is crucial for effective budgeting. According to a recent report by SmarTech Analysis, the global market for professional 3D printers is projected to grow at a compound annual growth rate (CAGR) of over 20% through 2025. This growth indicates a rising demand for 3D printing solutions, making comprehensive cost analysis essential for any business looking to stay competitive.

When budgeting for an enclosed 3D printer, consider not only the upfront cost of the machine—typically ranging from $2,500 to $10,000 depending on features and specifications—but also the ongoing operational expenses. The 3D printing industry report by Wohlers Associates states that materials can contribute up to 30% of the total operational costs. Additionally, maintenance and software licensing should also be factored into your financial planning. By carefully assessing these costs, businesses can make informed decisions, ensuring a balanced investment that aligns with their long-term operational goals and financial sustainability.

Ultimate Guide to Choosing the Best Enclosed 3D Printer for Your Business Needs - Cost Analysis: Budgeting for Your Enclosed 3D Printer Investment

| 3D Printer Model | Build Volume (mm) | Printing Speed (mm/s) | Material Compatibility | Estimated Cost (USD) | Maintenance Cost per Year (USD) |

|---|---|---|---|---|---|

| Model A | 250 x 250 x 300 | 50 | PLA, ABS, PETG | 2,000 | 300 |

| Model B | 400 x 400 x 500 | 60 | ASA, Nylon, TPU | 3,500 | 450 |

| Model C | 300 x 300 x 400 | 45 | PLA, ABS | 2,200 | 350 |

| Model D | 500 x 500 x 600 | 70 | PC, PETG | 4,500 | 500 |

Evaluating Workspace Requirements for Enclosed 3D Printers

When choosing an enclosed 3D printer for your business, evaluating your workspace requirements is crucial. An enclosed 3D printer provides significant benefits such as temperature stability, safety, and noise reduction, but it also requires careful consideration of the physical space it will occupy. Start by measuring your workspace dimensions and ensure that there is enough room not just for the printer itself, but also for maneuvering and maintenance. Remember that some printers may have additional equipment, such as filament storage or post-processing areas, which need to be factored into your space planning.

Tip: Ensure that your workspace allows for proper ventilation and air circulation. Enclosed 3D printers can produce fumes during the printing process, making it essential to have an adequate air exchange system set up to maintain a safe working environment.

Another aspect to consider is accessibility. Position your enclosed 3D printer in a location that minimizes obstructive pathways while allowing easy access for loading materials and performing maintenance tasks. This will improve efficiency and reduce downtime as you scale up your production needs.

Tip: Incorporate storage solutions within your workspace to keep filament and print supplies organized. Having dedicated storage helps to maximize your workspace and ensures you can easily access necessary materials when needed.

Tips for Maintenance and Longevity of Your Enclosed 3D Printer in a Business Setting

When investing in an enclosed 3D printer for your business, effective maintenance and longevity should be at the forefront of your considerations. A well-maintained printer not only extends the machine’s lifespan but also ensures consistent and high-quality output. According to a report by SmarTech Analysis, nearly 30% of companies experience production downtime due to inadequate maintenance of their 3D printing equipment. Regularly checking critical components such as the extruder, build plate, and enclosure seals can significantly mitigate these risks.

Additionally, implementing a routine cleaning schedule is essential. Filament residues can accumulate and affect print quality. Research from Gartner indicates that companies that adopt preventive maintenance practices can reduce costs by up to 25% in the long run. Moreover, using high-quality materials designed specifically for enclosed environments allows for better thermal stability, minimizing warping and improving overall print reliability. By prioritizing these maintenance strategies, businesses can not only enhance the performance of their enclosed 3D printers but also optimize their production processes.