Best Professional 3D Printers for Every Business Need?

In today's fast-paced business environment, the demand for a professional 3D printer is at an all-time high. According to Dr. Emily Chen, an industry expert, "Professional 3D printers are revolutionizing the way companies innovate and create." These machines have become vital tools for various sectors, from manufacturing to healthcare.

However, selecting the right professional 3D printer can be challenging. Businesses must consider their specific needs and budget constraints. Some printers excel in speed, while others focus on detail. Companies often overlook essential factors, leading to suboptimal choices. Understanding these nuances is crucial for maximizing efficiency.

As we explore the best professional 3D printers available, we will delve into their unique features, strengths, and weaknesses. Each model serves different needs, and no single printer is perfect for everyone. Companies must reflect on their abilities and requirements to find the ideal match in this evolving landscape.

Overview of 3D Printing Technology and Its Applications in Business

3D printing technology has transformed business operations. Its applications are vast, from prototyping to creating final products. Businesses can produce customized items and reduce time-to-market. This flexibility empowers companies, allowing rapid design changes and cost savings on inventory.

Consider the potential of producing custom solutions. Many industries, like healthcare and automotive, benefit significantly. However, it's essential to recognize the learning curve involved. Adopting this technology requires training and adaptation. Not every attempt may yield perfect results, and that's okay. Embrace the imperfections as a step towards mastery.

**Tip:** Start with small projects. Experimentation can drive innovation. Analyze results to improve processes. Collaborate with your team to harness creative ideas. Keep an eye on industry trends and advancements. Staying informed can elevate your business and keep you competitive.

Best Professional 3D Printers for Every Business Need

Key Factors to Consider When Choosing a Professional 3D Printer

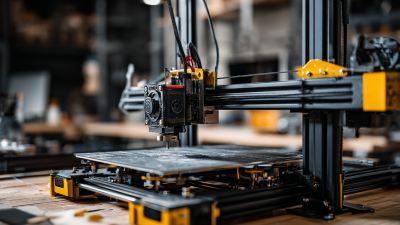

Choosing the right professional 3D printer involves several key factors. One important aspect is the printing technology. Different technologies yield different results. For example, resin printers provide high detail, while FDM printers offer versatility. Consider the specific needs of your projects. What level of detail do you require?

Material compatibility is another critical factor. Ensure the printer supports materials suitable for your applications. Some materials are stronger or more flexible than others. Consider how these properties will impact your designs. It’s also essential to think about post-processing needs. Some materials require extra work after printing.

Tips: Always request samples if possible. This helps you evaluate print quality firsthand. Don’t hesitate to ask for demonstrations. Understanding the workflow is equally vital. Take note of ease of use and customer support. A steep learning curve can hinder productivity. Remember, the cheapest option isn't always the best choice. Reflect on your long-term goals. Will this investment serve your needs tomorrow?

Top 3D Printers for Prototyping and Product Development Needs

When it comes to prototyping and product development, selecting the right 3D printer is crucial. Different industries require different features. Some may prioritize speed, while others focus on precision. A good printer can significantly reduce the time it takes to bring an idea to life. Often, businesses may overlook their specific needs. This leads to choices that don’t align with project demands.

Material versatility is key. Certain printers excel at using specialized materials, which can help in creating functional prototypes. However, not all materials are easy to work with. Businesses sometimes struggle with adhesion issues, warping, or post-processing challenges. Understanding these pros and cons is vital. Some features might seem appealing, but they could complicate the workflow.

Equally important is the printer’s ability to handle complex designs. Layer resolution impacts the final product quality. While high-resolution printers exist, they can require more maintenance. Users may find themselves reflecting on whether the benefits justify the extra effort. Balancing quality with usability can be a trial-and-error process, making the selection journey both rewarding and frustrating.

Best 3D Printers for Small and Medium-Sized Enterprises

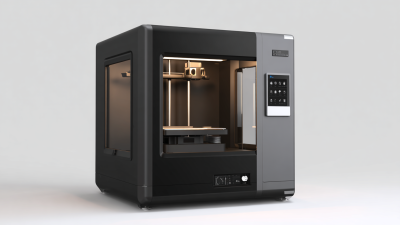

In today's competitive marketplace, small and medium-sized enterprises (SMEs) are turning to 3D printing to boost productivity. This technology offers flexibility in design and can reduce manufacturing costs. SMEs can produce prototypes or small batches of products quickly. However, choosing the right 3D printer is not always straightforward.

Several factors influence the decision. Print speed, material compatibility, and build volume are crucial considerations. Each business has unique needs. Some may prioritize speed for rapid prototyping, while others might focus on precision for detailed models. Finding the balance can be challenging and often requires trial and error. Misjudgments in selecting the right printer can lead to wasted time and resources.

Furthermore, there may be a learning curve involved. Employees need training to operate these machines effectively. Regular maintenance is also essential for optimal performance. Without it, a printer can become unreliable, affecting production timelines. Adopting 3D printing technology is a step forward, but businesses must remain open to adjustments and improvements as they navigate this new landscape.

3D Printers for Specialized Industries: Healthcare, Automotive, and More

In specialized industries like healthcare and automotive, 3D printing is transforming production processes. The global 3D printing market in healthcare was valued at approximately $1.5 billion in 2021, with an expected annual growth rate of 20.4% through 2030. This technology allows for the creation of customized medical implants and prosthetics. Such precision can lead to improved patient outcomes, although some practitioners still raise concerns about material reliability.

Automotive companies are also leveraging 3D printing. Reports show that 25% of manufacturers have adopted this technology to produce lightweight parts with complex geometries. This can reduce material waste significantly. Yet, challenges remain in scaling production for mass markets. Many manufacturers are still learning how to fully integrate new 3D printing technologies into existing workflows.

Despite these advancements, the journey is not flawless. Some 3D printed parts lack the durability of traditional components. Also, regulatory hurdles can delay implementation in industries like healthcare. As businesses navigate these challenges, critical thinking and reflection on both processes and outcomes are essential. The evolution of 3D printing holds great promise, but industry players must address these growing pains head-on.

Related Posts

-

Envisioning the Future of 3D Printing: Why the Best Desktop Models Will Lead Innovation

-

Understanding the Benefits of the Best Large 3D Printer for Global Buyers

-

Ultimate Guide to Finding the Best Professional 3D Printer for Your Business Needs

-

7 Digital Innovations Transforming the Professional 3D Printer Industry

-

20 Essential Tips for Selecting the Best Professional 3D Printer

-

How to Choose the Best Professional 3D Printer for Your Business Needs