Crafting Excellence with the Best Mini 3D Printer from China for Global Markets

As the demand for innovative manufacturing solutions continues to rise, the mini 3D printer market has emerged as a pivotal player in various industries. Recent industry reports indicate that the global 3D printing market is projected to reach $34.8 billion by 2024, with a significant portion of this growth driven by advancements in compact and efficient 3D printing technologies. Mini 3D printers, in particular, are gaining traction due to their affordability, versatility, and ease of use, making them ideal for both hobbyists and professionals alike.

Furthermore, with their capability to produce high-quality prototypes and personalized items, these printers are reshaping the landscape of product development and manufacturing. This blog will explore the top strategies for leveraging the best mini 3D printers from China to cater to global markets, ensuring excellence in craftsmanship and innovation.

Furthermore, with their capability to produce high-quality prototypes and personalized items, these printers are reshaping the landscape of product development and manufacturing. This blog will explore the top strategies for leveraging the best mini 3D printers from China to cater to global markets, ensuring excellence in craftsmanship and innovation.

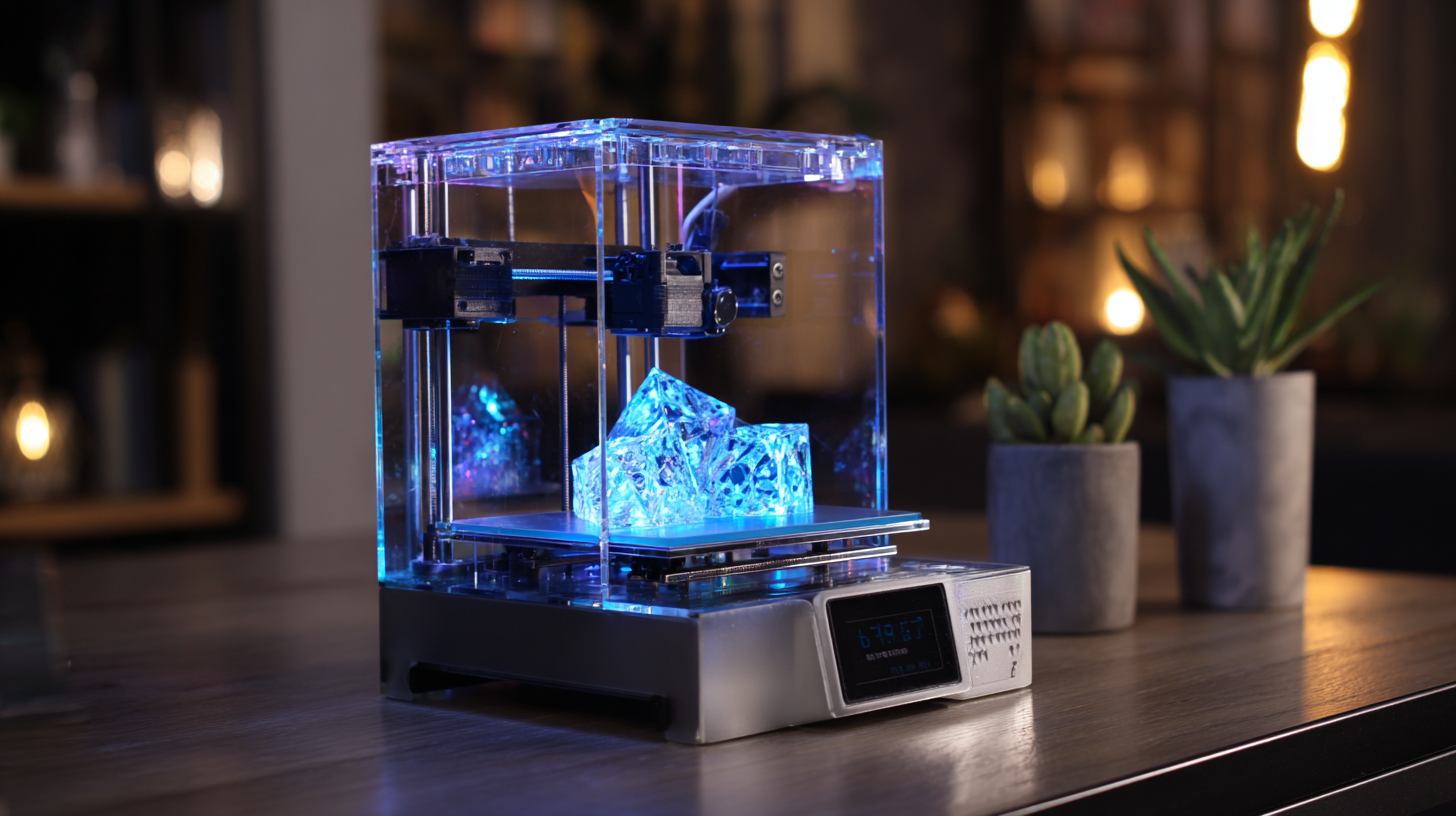

Unveiling the Technical Specifications of Premium Mini 3D Printers from China

The rise of mini 3D printers from China has revolutionized the global manufacturing landscape, thanks to their compact size and advanced technology. According to a recent report by MarketsandMarkets, the global 3D printing market is expected to reach $34.8 billion by 2026, with mini 3D printers playing a significant role due to their affordability and versatility. These premium devices typically boast features such as precise layer resolution of up to 50 microns, a build volume suitable for various applications, and compatibility with multiple filament types, which enhances their usability across different sectors.

When selecting a mini 3D printer, keep the following tips in mind: first, consider the printer's layer resolution, as finer details require higher precision. Additionally, check for a robust software suite that supports user-friendly design and operation—this is crucial for both beginners and seasoned users. Lastly, investigate the support and warranty options provided by the manufacturer to ensure assistance is available when needed.

Many of these printers also incorporate cutting-edge technologies such as auto-bed leveling and faster printing speeds, with some models achieving print times up to 30% quicker than their competitors. As these specifications continue to improve, the appeal of mini 3D printers from China in global markets is set to expand, offering innovative solutions for hobbyists and professionals alike.

Top Features to Look for in Mini 3D Printers for Optimal Performance

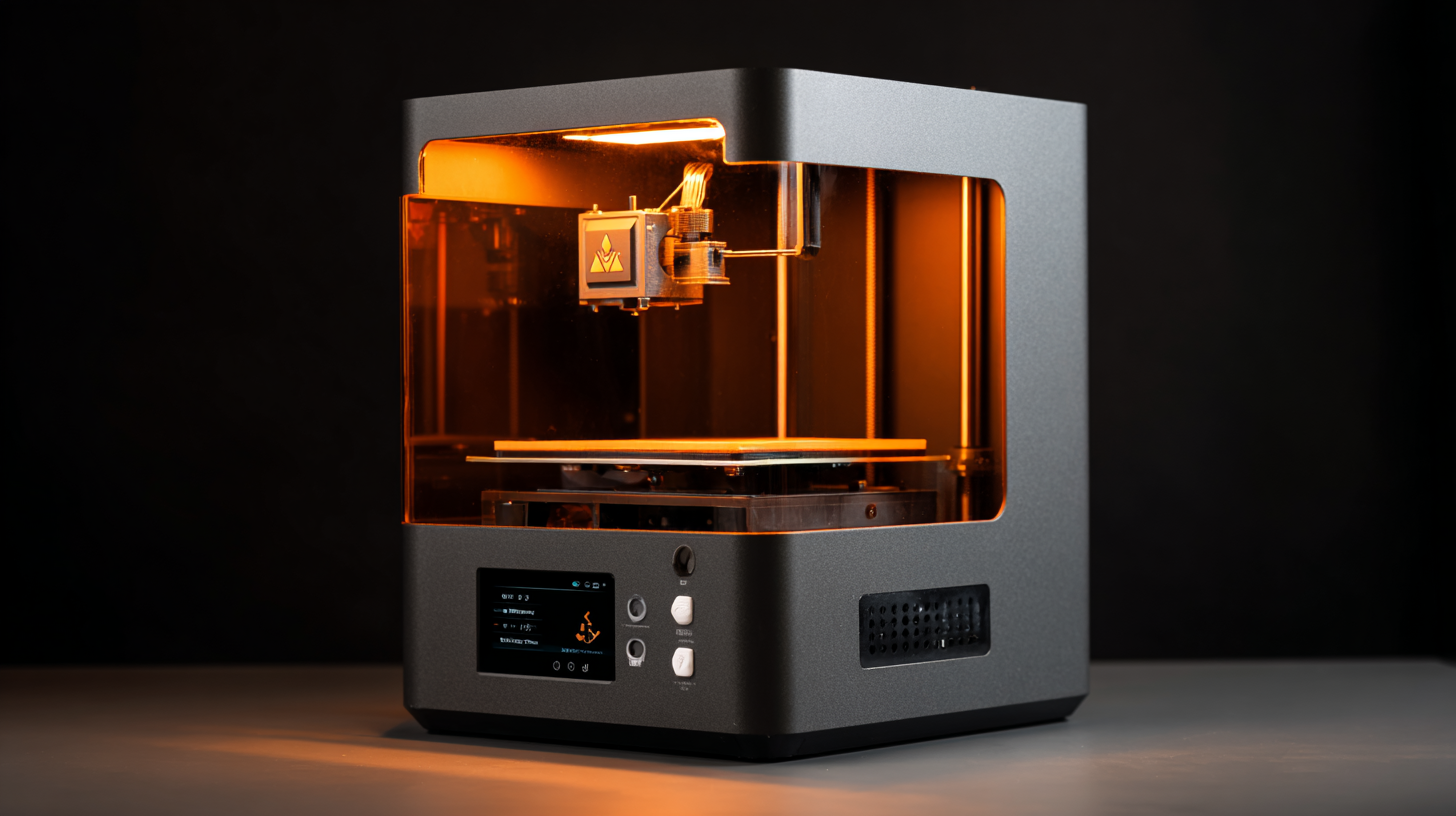

When exploring the realm of mini 3D printers, especially those exported from China to global markets, it’s crucial to identify the top features that contribute to optimal performance. First and foremost, a robust printing accuracy is essential; this ensures that intricate designs are rendered precisely, making it vital for applications ranging from hobbyist model making to professional prototyping. A reliable printer should also exhibit versatility in material compatibility, allowing users to experiment with different filaments or resins for a variety of projects.

Equally important is user-friendliness, particularly for beginners. Features such as intuitive slicing software and straightforward setup procedures can significantly enhance the 3D printing experience. Additionally, stability and reliability during prolonged printing sessions cannot be overlooked, as they minimize the risk of failed prints and wasted materials. Users will also appreciate having a compact footprint, making these devices suitable even for small workspaces. With advancements continuously emerging in the market, these attributes help ensure that a mini 3D printer not only meets current demands but also provides exceptional value for years to come.

Crafting Excellence with the Best Mini 3D Printer from China for Global Markets - Top Features to Look for in Mini 3D Printers for Optimal Performance

| Feature | Description | Importance | Average Rating |

|---|---|---|---|

| Print Quality | The level of detail and smoothness in printed objects. | Essential for professional applications. | 4.5/5 |

| Build Volume | The maximum size of objects that can be printed. | Important for larger projects. | 4.0/5 |

| Ease of Use | User-friendly software and assembly process. | Critical for beginners. | 4.8/5 |

| Material Compatibility | Supports a variety of filaments like PLA, ABS, PETG. | Allows versatility in projects. | 4.3/5 |

| Print Speed | How quickly the printer can create objects. | Important for production efficiency. | 4.2/5 |

| Technical Support | Availability of customer service and resources. | Vital for troubleshooting issues. | 4.6/5 |

| Price | Affordability relative to features offered. | Crucial for budget-conscious buyers. | 4.4/5 |

Comparative Analysis: Mini 3D Printers vs. Traditional 3D Printers

In recent years, the 3D printing industry has witnessed significant advancements, especially with the rise of mini 3D printers. According to a report by MarketsandMarkets, the global 3D printing market is projected to reach USD 34.8 billion by 2024, with mini 3D printers playing a vital role in this growth. Unlike traditional 3D printers, which often come with hefty price tags and complex operational requirements, mini 3D printers are designed to be more user-friendly and accessible, making them an appealing option for hobbyists and small businesses alike.

A comparative analysis reveals that mini 3D printers not only offer affordability but also enhanced portability and versatility. A study from ResearchAndMarkets indicates that mini 3D printers are generally 30-50% smaller in footprint compared to their traditional counterparts, allowing for easy placement in various environments, from home offices to workshops. Additionally, while traditional printers can be daunting for beginners, many mini models feature intuitive software interfaces and require minimal setup, enabling users to produce high-quality prints with less hassle. This democratization of 3D printing technology is enabling a new wave of creativity and innovation across various sectors.

Exploring Market Trends: Global Demand for Mini 3D Printers

The global demand for mini 3D printers is witnessing a significant surge, driven by the increasing interest in additive manufacturing across various sectors. By 2025, the surgical mesh market is expected to reach an estimated $3.565 billion, showcasing the broader trend where advanced manufacturing technologies are seamlessly integrating into medical applications. As manufacturers adapt their strategies to target niche markets, we observe an explosive 87% rise in shipping volumes for mini 3D printers, indicating a growing acceptance of these technologies among consumers.

This transition from a specialized domain, predominantly embraced by enthusiasts and creators, to widespread consumer adoption highlights the evolving landscape of 3D printing. Companies are actively working on enhancing the user-friendliness and accessibility of their devices, making it increasingly feasible for general consumers to tap into the transformative potential of 3D printing. This shift not only opens new avenues for creative expression but also paves the way for innovative applications that can redefine traditional manufacturing processes, suggesting a promising future for mini 3D printers on the global market.

Innovative Applications of Mini 3D Printers in Various Industries

The rise of mini 3D printers is reshaping various industries, presenting innovative applications that enhance efficiency and creativity. As the 3D printing market is predicted to surpass $40 billion by 2030, the integration of these compact printers in sectors like healthcare, construction, and retail is becoming increasingly evident. The ability to create custom products on demand allows businesses to minimize waste and optimize production cycles, catering directly to consumer needs.

In the healthcare industry, for example, mini 3D printers are revolutionizing patient care by enabling the rapid production of customized prosthetics and dental appliances. This not only accelerates the manufacturing process but also improves patient outcomes. Meanwhile, in construction, the convergence of 3D printing, artificial intelligence, and the Internet of Things is paving the way for eco-friendly and intelligent housing solutions. As these technologies mature, small and medium enterprises can leverage affordable mini 3D printers to innovate and capture new market opportunities, positioning themselves at the forefront of this transformative landscape.